| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10169898

Manufacturer Communication Number: TSB 19-2390

Summary

Some 2015-2019 F-150, 2015-2020 Explorer, 2017-2019 F-Super Duty, 2017-2020 Continental, 2018-2020 Expedition/Navigator, 2016-2018 MKX, 2019-2020 Nautilus, 2020 Aviator/Corsair and 2013-2020 MKZ vehicles equipped with multi-contour seats may exhibit intermittent multi-contour seat operation and/or massage and lumbar adjust inoperative from the seat switch or SYNC screen with or without diagnostic trouble code (DTC) B1471, U024B, and/or U024C. This may be due to terminal fretting at the connector for the driver multi-contour seat module (SCMG) and passenger multi-contour seat module (SCMH). To correct the condition, follow the Service Procedure steps to replace the connectors and reroute the harness.

39 Affected Products

Vehicles

FORD | EXPLORER | 2015-2019 |

FORD | F-150 | 2015-2019 |

FORD | F-250 SD | 2017-2019 |

FORD | F-350 SD | 2017-2019 |

FORD | F-450 SD | 2017-2019 |

FORD | F-550 SD | 2017-2019 |

LINCOLN | AVIATOR | 2020 |

LINCOLN | CORSAIR | 2020 |

LINCOLN | MKX | 2016-2019 |

LINCOLN | MKZ | 2013-2020 |

LINCOLN | NAVIGATOR | 2018-2020 |

This bulletin supersedes 19-2293. Reason for update: Concern Carryover to New Model

Model:

2018-2020 Expedition

2015-2020 Explorer

2015-2019 F-150

2017-2019 F-Super Duty

2020 Aviator

2017-2020 Continental

2020 Corsair

2016-2018 MKX

2013-2020 MKZ

2019-2020 Nautilus

2018-2020 Navigator

Summary

This article supersedes TSB 19-2293 to update the vehicle model years affected.

Issue: Some 2015-2019 F-150, 2015-2020 Explorer, 2017-2019 F-Super Duty, 2017-2020 Continental,

2018-2020 Expedition/Navigator, 2016-2018 MKX, 2019-2020 Nautilus, 2020 Aviator/Corsair and 20132020 MKZ vehicles equipped with multi-contour seats may exhibit intermittent multi-contour seat operation and/or massage and lumbar adjust inoperative from the seat switch or SYNC screen with or without diagnostic trouble code (DTC) B1471, U024B, and/or U024C. This may be due to terminal fretting at the connector for the driver multi-contour seat module (SCMG) and passenger multi-contour seat module (SCMH). To correct the condition, follow the Service Procedure steps to replace the connectors and reroute the harness.

Action: Follow the Service Procedure steps to correct the condition on vehicles that meet all of the following criteria:

- One of the following vehicle lines:

- 2015-2019 F-150

- 2017-2019 F-Super Duty

- 2017-2020 Continental

- 2018-2020 Expedition/Navigator

- 2016-2018 MKX

- 2019-2020 Nautilus

- 2013-2020 MXZ

- 2015-2020 Explorer

- 2020 Aviator/Corsair

- Equipped with multi-contour seats

- Customer symptom of intermittent multi-contour seat operation and/or massage and lumbar adjust inoperative from the seat switch or SYNC

Parts

| Description | Quantity | Part Number | |

| 2 Kits Required, 1 Kit Per Side | Pigtail Kit (2 Kits Required, 1 Kit Per Side) | 2 | KU2Z-14S411FA |

| Package Contains 4 Pieces, 4 Pieces Required, 2 Per Seat | Front Seat Bolts (Navigator Only, Package Contains 4 Pieces, 4 Pieces Required, 2 Per Seat) | 1 | W719352S451 |

| Package Contains 4 Pieces, 4 Pieces Required, 2 Per Seat | Front Seat Bolts (Navigator Only, Package Contains 4 Pieces, 4 Pieces Required, 2 Per Seat) | 1 | W718633S451 |

| Package Contains 50 Pieces, 2 Pieces Required, 1 Per Seat | Zip Tie Or Equivalent, Length Of 280 mm (11 In.) (Package Contains 50 Pieces, 2 Pieces Required, 1 Per Seat) | As Needed | WA-14-SBA |

| – | Rotunda Coroplast Wiring Harness Tape Or Equivalent | As Needed | NAI837X |

| – | Rosin Core Mildly-activated (RMA) Solder | As Needed | Obtain Locally |

SEOCONTENT-START

TECHNICAL SERVICE BULLETIN

Multi-Contour Seats – Intermittent Multi-Contour Seat Operation

And/Or Massage And Lumbar Adjust Inoperative

Warranty Status: Eligible under provisions of New Vehicle Limited Warranty (NVLW)/Service Part

Warranty (SPW)/Special Service Part (SSP)/Extended Service Plan (ESP) coverage. Limits/policies/prior

approvals are not altered by a TSB. NVLW/SPW/SSP/ESP coverage limits are determined by the

identified causal part and verified using the OASIS part coverage tool.

Labor Times

Description

Operation

No.

Time

2015-2019 F-150, 2018-2020 Expedition: Retrieve DTCs And Install Pigtail In Both

(2) Front Seats Includes Time To Remove And Install Seat (Do Not Use With Any

Other Labor Operations)

192390A 3.5

Hrs.

2017-2020 Continental, 2020 Aviator: Retrieve DTCs And Install Pigtail In Both (2)

Front Seats Includes Time To Remove And Install Seat (Do Not Use With Any

Other Labor Operations)

192390B 2.5

Hrs.

2018-2020 Navigator: Retrieve DTCs And Install Pigtail In Both (2) Front Seats

Includes Time To Remove And Install Seat (Do Not Use With Any Other Labor

Operations)

192390C 2.4

Hrs.

2013-2020 MKZ, 2016-2020 MKX, 2019-2020 Nautilus: Retrieve DTCs And Install

Pigtail In Both (2) Front Seats Includes Time To Remove And Install Seat (Do Not

Use With Any Other Labor Operations)

192390D 3.5

Hrs.

2017-2019 F-Super Duty: Retrieve DTCs And Install Pigtail In Both (2) Front Seats

Includes Time To Remove And Install Seat (Do Not Use With Any Other Labor

Operations)

192390E 3.6

Hrs.

2015-2019 Explorer: Retrieve DTCs And Install Pigtail In Both (2) Front Seats

Includes Time To Remove And Install Seat (Do Not Use With Any Other Labor

Operations)

192390F 3.3

Hrs.

2020 Explorer/Corsair: Retrieve DTCs And Install Pigtail In Both (2) Front Seats

Includes Time To Remove And Install Seat (Do Not Use With Any Other Labor

Operations)

192390G 3.0

Hrs.

Repair/Claim Coding

Causal Part: 14D232

Page 2 of 5

https://www.fordservicecontent.com/Ford_Content/vdirsnethttps://static.oemdtc.com/TSB/EU/~WTSB19-2390/US/E… 1/3/2020

Condition Code: X4

Service Procedure

NOTE: Perform this procedure on both front seats.

- Remove the seat cover to access the SCMH and SCMG module. Refer to the Workshop Manual (WSM), Section 501-10A.

- Remove the harness shied to seat back frame retention clips and separate the plastic shield from the harness to access the circuits.

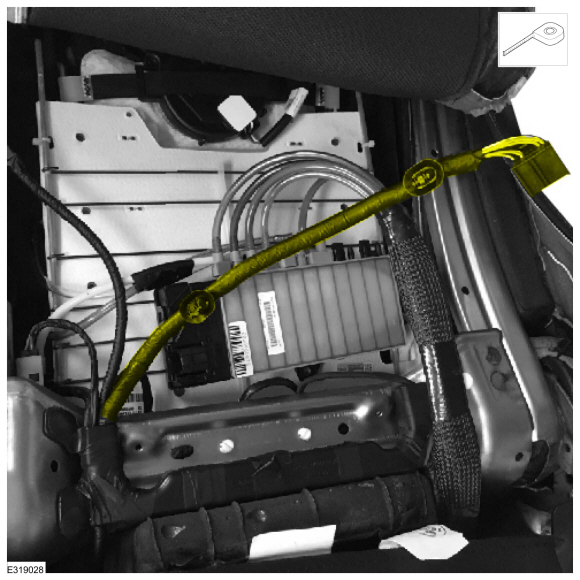

- Measure back 150 mm (5.9 in) from the edge of the plastic shield and mark the circuits to determine the cut location. The finished harness must extend a minimum of 300 mm (11.8 in) beyond the edge of the plastic shield. (Figure 1)

(1). The circuits for the left seat will run to the right side of the seat and the circuits for the right seat will run down toward the floor.

NOTE: Do not use the butt connectors included with the pigtail kit for this repair. Each circuit must be connected with solder and covered with heat shrink tubing.

Figure 1

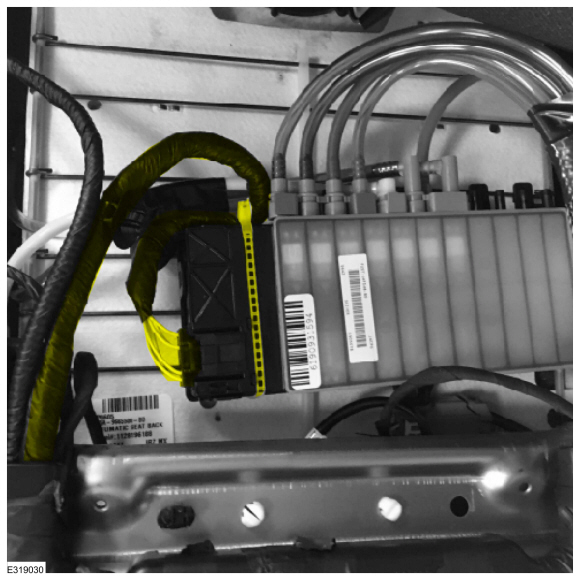

(1). Cut, solder, and heat shrink each circuit one at a time following the instructions included with the kit. (Figure 2)

Figure 2

- Wrap the new wiring with Coroplast tape or equivalent from the plastic harness shield to the connector.

- Install the plastic harness shield and secure with the 4 retention clips.

- Measure 105 mm (4.13 in) from the back for the new harness connector shell and place a mark on the new harness.

- Connect the new connector to the module and loop the harness above the module placing the mark on the harness applied in Step 7 on the top of the module next to the tube connections. (Figure 3)

Figure 3

- Secure the new harness to the module body using a minimum 280 mm (11 in) long zip tie.

- Reinstall the seat back cover. Refer to the WSM, Section 501-10A.

19-2390

19 December 2019

Loading...

Loading...

19-2293

26 September 2019

Loading...

Loading...

- [EXECELLENT QUALITY] - Direct factory with excellent quality control, STRONG & DURABLE. The copper core of our heat shrinkable joints is made of high quality tinned copper, in addition to being extremely conductive, it is easier to flatten and grip the wire

- [WATERPROOF] - Waterproof insulated, the polyolefin tubing on the outside and the hot-melt glue inner layer provide excellent water resistance when heated. The polyolefin tube reduces in size and the adhesive flows within the insulation

- [PERFECT FOR] - Perfect use for the repair technician on the electrical wiring. Seamless copper barrel design provides high tensile strength and mechanical damage resistance, translucent heat shrink tubing eliminates the issue of the barrel opening, high elasticity keeps steady performance

- [EASY USE] - Take two wires you wish to join. Remove the wire insulator, pick the terminal color you want. Insert the wire into the terminal one at the time and crimp by crimping tool, insert another terminal and crimp. Use air gun to apply heat on the heat shrink connectors

- [PACKAGE INCLUDES] - 200pcs Heat Shrink Butt Connectors. 3 Sizes, 90pcs Red, 9Opcs Blue and 20pcs Yellow.

- High-quality Material: Wire butt connectors are made of high-end brass conductor ( tin-plated finish ), PVC insulation

- Flared Insulation: Flared barrel design of insulated butt crimp connectors is easy to insert

- Wire-stop Structure: Wire-stop structure of butt splice terminals is conducive to inserting wires into the right place to ensure the effect of compression

- Practical Crimp Connectors: With the electronic wiring splice connectors, one or more different conductors can be crimped in a short space, which is ideal for automotive, home, scientific, car stereo, or occasional project

- Package included: Total 200 pcs, 90 pcs red connectors for 22-16 AWG, 80 pcs blue connectors for 16-14 AWG, 30 pcs yellow butt connectors for 12-10 AWG

- PREMIUM COPPER CORE AND HEAT SHRINK TUBE: Made of high quality tinned copper and adhesive lined heat shrink tubing. These professoinal butt connectors ensure protection against the elements. Heat shrink tubing provides high tensile strength and resistance to stretch and mechanical damage, high thickness copper core ensure protection against the elements

- STRONG CRIMPS: These butt connectors use thick, seamless copper barrels. Your wire will not pull out of these butt splices when crimping

- EXCELLENT WIRE CONTACT: The copper barrel provides increased current flow, and ensures less voltage drop, preventing wiring failures and reducing equipment downtime

- RELIABLE CONNECTION: Adhesive lined inside the 3:1 butt heat shrink connector will exude hot melt adhesive when evenly heated, shrinks quickly and adheres to wire insulation. Guarantees good environmental sealing, waterproof and wear-resistant

- WIDE APPLICATIONS: Excellent stability, water resistance and electrical conductivity provide durable connection for motorcycle, off-road vehicles, lawn tractors,RVs,fish finder and marine application. Widely used on multiple projects of your Christmas lights,ships with high waterproof requirements motorcycle stereo, boat electronics, equipment switches

- [EXECELLENT QUALITY] : Direct factory with excellent quality control, STRONG & DURABLE. The copper core of our heat shrinkable joints is made of high quality tinned copper, in addition to being extremely conductive, it is easier to flatten and grip the wire

- [EASY USE] : Take two wires you wish to join. Remove the wire insulator, pick the terminal color you want. Insert the wire into the terminal one at the time and crimp by crimping tool, insert another terminal and crimp. Use air gun to apply heat on the heat shrink connectors.

- [PRACTICAL DESIGN] : Double-wall design, outer layer of polyolefin tube, inner layer of hot melt adhesive, precise crimping and good contact. Electrical butt connectors provide high tensile strength and adequate hot melt adhesive inside the tube. After shrinking, the wiring is firm and not loose, and it can ensure that the current continues to flow smoothly.

- [WIDE APPLICATIONS] : Our waterproof terminals are perfect for marine, automobile applications, electrical and electronics industries. Whether working on your Boat, Vehicle, Home, or Scientific project, the electrical crimp connector will ensure a strong waterproof seal to make sure everything bonds correctly.

- [PACKAGE INCLUDED] : 25 pcs red connector ( 22-16 AWG ), 15 pcs blue connector ( 16-14 AWG ), 10 pcs yellow connector ( 12-10 AWG ).

- HIGH-QUALITY MATERIAL: Wire butt connectors are made of top brass ( tin-plated finished ), PVC insulation

- FLARED INSULATION: Flared barrel design of insulated butt crimp connectors is easy to insert

- WIRE-STOP STRUCTURE: Wire-stop structure of butt splice terminals is conductive to insert wires into the right place to ensure the effect of compression

- PRACTICAL CRIMP CONNECTORS: With the electronic butt connectors, one or more different conductors can be crimped in a short space

- Quantity: 100 PCS 22-16 AWG butt crimp connectors red

- Tinned Copper Core: Butt connectors use a heavy-duty copper core, strong crimp, higher conductivity

- Package Includes: 100Pcs Blue heat shrink butt connectors that can be used on wire AWG from 16 to 14

- Solderless Crimping: Insert the wires to be connected, crimp both sides with crimping pliers, and then heat with a heat gun

- 3:1 Shrink Ratio: Marine grade heat shrink tubing provides high tensile strength and enough hot melt adhesive inside the tubing to ensure waterproof performance, your wires will never slip out of the wire connectors

- Wide Application: Wire connectors are waterproof, stable, and corrosion resistant and are used in the automotive, marine, electrical, and electronic industries

- COMPLIANT WITH ALL RELEVANT STANDARDS:With Haisstronica 330PCS( A.W.G.:22-16 150 PCS,16-14 100 PCS,12-10 32 PCS,26-24 48 PCS) heat shrink waterproof wire connectors are compliant with ROHS, ISO 9001:2008, SGS, and CE standards

- HIGH-QUALITY COPPER CORE:Heat shrink butt connectors use a copper core with a higher thickness rating.This makes your connection project safer and better meets our customers’ quality needs

- HIGH-QUALITY HEAT SHRINK:Translucent heat shrink tubing provides high tensile strength and resistance to stretch and minimize mechanical damage.The thick barrel ensures a strong crimp every time.The inner wall of the heat-shrinkable tube has enough hot melt adhesive to ensure waterproof performance reliability.Your wire will never slip out of these heat shrink wire connectors

- RECOGNIZABLE:Tubings of varying colors with easily recognizable wire gauge markings. Simply measure the wiring, and by checking the mark of wire gauge of the polyolefin tubing, then you can quickly choose the right connector

- WIDE APPLICATIONS: High quality 3:1 shrinkage tubing has a heat-activated sealant lining to provide complete secure seal. It's flame-retardant, waterproof, and can be used underground. Compliant with all electrical standards, Perfect for marine and automobile applications, whether you are working on your boat, Vehicle, Home or scientific project

- 【PREMIUM IN QUALITY】- Every single piece of our crimp connectors is made with tinned thick red copper barrel and polyolefin heat shrink tubing[Shrink Ratio 3:1], which ensure secure crimping and tight wire connection with high current flow and minimum voltage drop, preventing wire failures

- 【SAFETY MATTERS】- Safety is the top priority during any of your work, certificated products can ensure you reassured and secure using experience. Our heat shrink connectors meet the standards of CE, RoHS, ISO9001, SGS, you’re allowed to use these proffesional butt splice connectors with full confidence for a variety of electrical projects and wire connection issues

- 【MADE TO LAST】- Thanks to the thick tinned copper and seamless barrel desgin, it ensures strong and secure crimping all the time with no wire coming off issues. What's more, the polyolefin heat shrink tubing provides the high tensile strength and resistance to mechanical damage so there's no worry of rat chewing or similiar phisical damage issues. When heated with a heat gun, the adhesive melting inside create a waterproof and insulated seal, preventing electric leakage and corrosion

- 【WIDE APPLICATION】- Marine grade heat shrink butt splices can be widely applied in areas such as automotive industry, marine, science projects, family electrical wire connections and so on, due to its durability, steadily, water and corrosion resistace

- 【COST EFFECTIVE PACKAGE】- Considerate product quantity of 100pcs/pack

- ✔️【PREMIUM QUALITY】Thick copper barrel ensures strong secure crimping every time, providing minimal voltage drop, high current flow, and less heat. These will prevent short circuits and problematic wiring that inferior connectors are known for

- ✔️【DURABILITY】Each terminal features a thick tinned copper barrel that resists corrosion to hold the wire tight when crimped. The barrel is created from one seamless piece of copper that eliminates the problem of the barrel opening. Your wire will never slip out of the connector

- ✔️【WATERPROOF】Insulation tubing has unique dual-walled design. High quality 3:1 shrinkage tubing has a heat-activated sealant lining to provide a 360 degree secure seal. It's flame-retardant, waterproof, and can be used underground

- ✔️【WIDE APPLICATIONS】Compliant with all electrical standards, Perfect for marine and automobile applications, whether you are working on your boat, Vehicle, Home or scientific project, our electrical crimp connector will ensure strong watertight seal to make sure everything bond correctly. The connector assortment includes red (AWG 22 – 16), blue (AWG 16 – 14) and yellow (AWG 12 – 10) butt connectors that can be used on wire AWG from 22 to 10

- ✔️【TICONN BRAND QUALITY COMMITMENT】We stand behind the quality of our products. If for any reason you are not satisfied with your purchase, please contact us. We provide 30-day money back and 24-month warranty. 100% Satisfaction Guarantee for risk-free shopping!

- EASY TO IDENTIFY- Easier to choose the correct heat shrink connector, different color coded tubing with wire gauge imprint provides easy identification.

- WATERPROOF- Polyolefin tubing on the outside and hot melt adhesive inside provides excellent waterproof property. Polyolefin tubing reduces in size and adhesive flows inside the insulation when heating.

- HIGH QUALITY- Thick barrel ensures strong secure crimping every time to prevent wire failure, increase current flow, decrease voltage drop, and reduce equipment downtime. Your wire will never slip out of the connector.

- DURABILITY- Seamless copper barrel design provides high tensile strength and extreme stretch and mechanical damage resistance, translucent heat shrink tubing eliminates the issue of the barrel opening, high elasticity keeps steady performance.

- COMPLIANT WITH ALL ELECTRICAL STANDARDS - Qibaok heat shrink connectors are compliant with ROHS, ISO 9001:2008, SGS and CE standards.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.