| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10169880

Manufacturer Communication Number: TSB19-2374

Summary

Some 2015-2019 F-150, 2017-2019 F-Super Duty, 2018-2019 Expedition/Navigator vehicles may exhibit a rattle and/or squeak noise from the vista roof opening panel while driving with the roof opening panel closed. This may be due to dirt and/or debris build up between the vista roof opening panel seal and the body. To correct the condition, follow the Service Procedure steps to clean and lubricate the vista roof opening panel seal.

21 Affected Products

Vehicles

FORD | EXPEDITION | 2018-2019 |

FORD | F-150 | 2015-2019 |

FORD | F-250 SD | 2017-2019 |

FORD | F-350 SD | 2017-2019 |

FORD | F-450 SD | 2017-2019 |

FORD | F-550 SD | 2017-2019 |

LINCOLN | NAVIGATOR | 2018-2019 |

This bulletin supersedes 19-2169. Reason for update: Concern Carryover to New Model

Model:

2015-2019 F-150

2017-2019 F-Super Duty

2018-2019 Expedition

2018-2019 Navigator

Summary

This article supersedes TSB 19-2169 to update the vehicle lines, Service Procedure, and Part List.

Issue: Some 2015-2019 F-150, 2017-2019 F-Super Duty, 2018-2019 Expedition/Navigator vehicles may exhibit a rattle and/or squeak noise from the vista roof opening panel while driving with the roof opening panel closed. This may be due to dirt and/or debris build up between the vista roof opening panel seal and the body. To correct the condition, follow the Service Procedure steps to clean and lubricate the vista roof opening panel seal.

Action: Follow the Service Procedure steps to correct the condition on vehicles that meet the following criteria:

- One of the following vehicle lines:

- 2015-2019 F-150

- 2017-2019 F-Super Duty

- 2018-2019 Expedition/Navigator

- Customer symptom of rattle and/or squeak from the vista roof opening panel while driving

Parts

| Description | Quantity | Part Number |

| Krytox® Weather Strip Lube Or Equivalent | As Needed | 164-WS0850102 |

| Krytox® Grease Or Equivalent | As Needed | 164-R4906 |

| Isopropyl Alcohol Or Equivalent | As Needed | Obtain Locally |

SEOCONTENT-START

TECHNICAL SERVICE BULLETIN

Vista Roof – Rattle And/Or Squeak Noise While Driving With

Roof Opening Panel Closed

Warranty Status: Eligible Under Provisions Of New Vehicle Limited Warranty Coverage Warranty/ESP coverage limits/policies/prior approvals are not altered by a TSB. Warranty/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool.

Labor Times

| Description | Operation No. | Time |

| 2015-2019 F-150, 2017-2019 F-Super Duty, 2018-2019 Expedition/Navigator: Clean And Lubricate Rubber Seals Following The Service Procedure (Do Not Use With Any Other Labor Operations) | 192169A | 0.4

Hrs. |

Repair/Claim Coding

| Causal Part: | 16500A18 |

| Condition Code: | 07 |

SEOCONTENT-END

Service Procedure

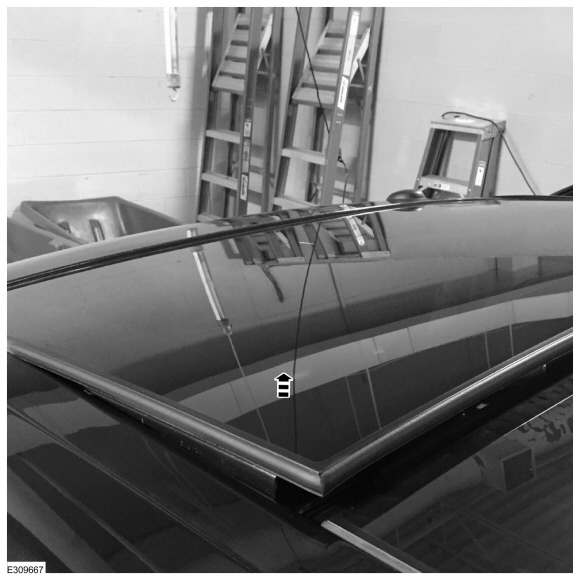

- Position the glass panel to the vent position. (Figure 1)

Figure 1

- Clean the rear and side rubber seals of the movable glass panel with isopropyl alcohol or equivalent.

- Clean the exposed sheet metal of the roof opening with isopropyl alcohol or equivalent.

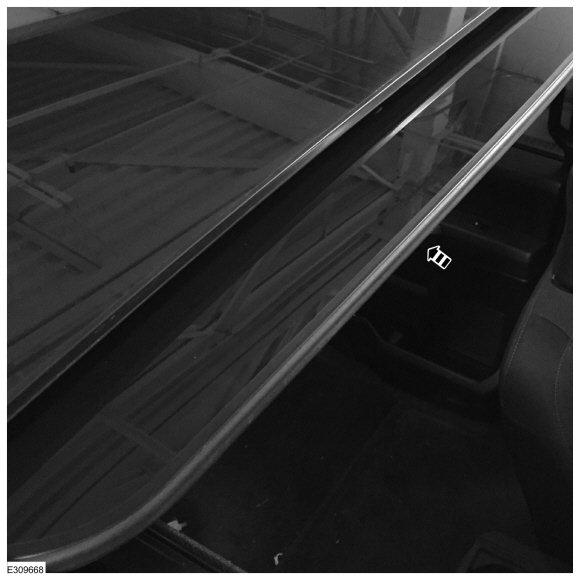

- Position the glass panel to the fully open position. (Figure 2)

Figure 2

- Clean the remaining front rubber seal area of the movable glass panel with isopropyl alcohol or equivalent.

- Clean the remaining exposed sheet metal of the roof opening with isopropyl alcohol or equivalent.

- Apply isopropyl alcohol or equivalent onto a clean cloth and insert it between the rear fixed glass panel rubber seal and the roof opening sheet metal. (Figure 3)

(1). Folding the cloth over a flexible piece of plastic such as an old credit card or a thin piece of plexiglass will assist in the cleaning process.

(2). Slide the isopropyl alcohol soaked cloth around all sides of the fixed panel glass and rubber bulb seal.

Figure 3

- Apply a light film of Krytox® Weather Strip Lube to the entire front moveable glass panel rubber bulb seal and rear fixed glass panel rubber bulb seal that contacts the sheet metal opening of the roof opening panel.

(1). Folding a clean rag over a flexible piece of plastic such as an old credit card or a thin piece of plexiglass will assist in application process.

(2). Slide the Krytox® Weather Strip Lube soaked rag around all sides of the fixed panel glass and rubber bulb seal.

- Hold the wind deflector down and apply Krytox® Grease to both openings of the left and right front set plates. (Figure 4)

Figure 4

- Cycle the glass from open to closed, closed to vent, vent to closed, closed to open and open to closed.

19-2374

13 December 2019

Loading...

Loading...

19-2169

28 May 2019

Loading...

Loading...

- Temp Range: -36C thru 204C: Viscosity 18cSt/100C, 160cSt/40C; Stable in a wide variety of operating conditions/environments

- Nonflammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

- Temp Range: -36C thru 260C: Viscosity 25cSt/100C, 240cSt/40C; Stable in a wide variety of operating conditions/environments

- Nonflammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

- Temp Range: -51C thru 179C: Viscosity 9cSt/100C, 60cSt/40C; Stable in a wide variety of operating conditions/environments

- Nonflammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

- Temp Range: -36C thru 204C: Viscosity 18cSt/100C, 160cSt/40C; Stable in a wide variety of operating conditions/environments

- Nonflammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

- Temp Range: -30C thru 288C: Viscosity 42cSt/100C, 440cSt/40C; Stable in a wide variety of operating conditions/environments

- Nonflammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

- Temp Range: -36C thru 204C: Viscosity 18cSt/100C, 160cSt/40C; Stable in a wide variety of operating conditions/environments

- Nonflammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

- Best for Corrosive environments; Contains Sodium Nitrite: Temp Range: -36C thru 204C: Viscosity 18cSt/100C, 160cSt/40C; Stable in a wide variety of operating conditions/environments

- Non-flammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

- Keyboard Lube: krytox 205g0 This high viscosity lubricant is optimised to silence keyboard stabilisers and comes in a convenient ml syringe that fits inside your stabiliser.Lubrication Amount Approximately 280 switches or more

- Easy to use: Remove the stabiliser keycaps and surrounding keycaps, use a small amount of lube to lift the stabiliser shaft to make room for the syringe.

- Lube Syringe Works on any Mx-style mechanical keyboard stabiliser where a metal wire is in contact with a plastic housing. Be careful not to use too much as this will result in sluggish stabilisers.

- Syringe and Luer tips: The best way to know exactly how much lubricant you're getting and the most efficient way to dispense EVERY DROP.

- krytox 205g0 Switch Lube Kit Makes a new mechanical keyboard feel "broken in" and switches feel ultra-smooth, eliminating "scratching" noises.

- Temp Range: -63C thru 132C: Viscosity 3cSt/100C, 15cSt/40C; Stable in a wide variety of operating conditions/environments

- Nonflammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

- Best for Corrosive environments; Contains Sodium Nitrite: Temp Range: -36C thru 260C: Viscosity 25cSt/100C, 240cSt/40C; Stable in a wide variety of operating conditions/environments

- Nonflammable: Krytox Grease contains only carbon, oxygen & fluorine, (no hydrogen or silicone); Will not burn or support combustion; Passes impact standards with LOX, Nitrogen Tetroxide, Nitric Acid

- Chemically Inert: Resistant to oxygen and inert to most all chemicals; Inert nature allows Krytox Grease to outlast/outperform hydrocarbon products; Chemically insoluble in nearly all solvents

- At operating temps and pressures Krytox Grease is highly resistant to attack by gaseous and liquid oxygen; The preferred choice in oxygen; use and manufacturing industry

- Exposure to significant radiation causes only minor DE polymerization (8% decrease of viscosity) and no formation of solids or sludge or change in appearance

Last update on 2025-05-10 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.