| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10168821

Manufacturer Communication Number: 18N03-S7

Summary

Customer Satisfaction Program 18N03 – Supplement #7

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550

Vehicles – Door Latch Freezing Concerns

November 21, 2019

Customer Satisfaction Program 18N03 – Supplement #7

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550

Vehicles – Door Latch Freezing Concerns

PROGRAM TERMS

This is a one-time repair program for vehicle owners that report a door latch freezing concern. Affected vehicles are eligible for this repair through October 31, 2028, regardless of vehicle mileage or warranty start date. Coverage is automatically transferred to subsequent owners. This program will expire October 31, 2028.

REASON FOR THIS SUPPLEMENT

Technical Information: Updated with revised directions regarding the inspection of the interior door handle release cables. As a result, the Labor Allowances and the Parts Requirements / Ordering Information have also been updated.

VEHICLES COVERED BY THIS PROGRAM

| Vehicle | Model Year | Assembly Plant | Build Dates |

| F-150 | 2015-2018 | Dearborn | March 12, 2014 through April 12, 2018 |

| Kansas City | August 11, 2014 through April 3, 2018 | ||

| F-250 – F-550 | 2017-2018 | Kentucky | October 8, 2015 through April 21, 2018 |

| OHAP | February 5, 2016 through April 17, 2018 |

REASON FOR PROVIDING EXTENDED WARRANTY COVERAGE

In the affected vehicles, water entering the doors in cold temperatures can cause door latching components to freeze. Ford is offering this no charge service to customers that have experienced a frozen door latch to install additional sealing to the front doors and crew cab rear doors, which will prevent water intrusion and door latch freezing.

is offering this no charge service to customers that have experienced a frozen door latch to install additional sealing to the front doors and crew cab rear doors, which will prevent water intrusion and door latch freezing.

SERVICE ACTION

If an affected vehicle owner has reported a frozen latch concern, dealers are to install additional sealing to the front doors and crew cab rear doors, lubricate certain door latch, door handle and cable components, clean the door drain holes, inject windshield wash concentrate or a methyl hydrate (methanol) product into the exterior door handle cables and install a wiper clip on the exterior door handle cable ends. This service must be performed at no charge to the vehicle owner.

Note: The technical instructions for this program include all additional steps required to also complete safety recall 17S33, if 17S33 is open.

OWNER NOTIFICATION AND MAILING SCHEDULE

Owners of affected vehicles have been notified. Dealers should repair any affected vehicles that experience a frozen door latch whether or not the customer has received a letter.

SOLD VEHICLES

- Only owners with affected vehicles that exhibit the covered condition will be directed to dealers for repairs.

- Dealers are to prioritize repairs of customer vehicles over repairs of new and used vehicle inventory.

STOCK VEHICLES

Do not perform this program unless the affected vehicle exhibits the covered condition.

TITLE BRANDED / SALVAGED VEHICLES

Affected title branded and salvaged vehicles are eligible for this service action.

OWNER REFUNDS

Refunds are not approved for this program.

RENTAL VEHICLES

The use of rental vehicles is not approved for this program.

PARTS REQUIREMENTS

| Description | Part Number | Order Quantity | Claim Quantity |

| Front Doors Foam Kit (F-150 Built Prior to December 2016*) | FL3Z-16308-L | As required | |

| Front Doors Foam Kit (F-150 Built December 2016 or later and All F-Super Duty*) (New Kit)*** | FL3Z-16308-P | As required | |

| Front Doors Foam Kit (F-150 Built December 2016 or later and All F-Super Duty*) (Old Kit)*** | FL3Z-16308-M | ||

| Rear Doors Foam Kit (crew cab only) (New Kit)*** | FL3Z-16308-Q | As required | |

| Rear Doors Foam Kit (crew cab only) (Old Kit)*** | FL3Z-16308-N | ||

| Exterior Door Handle Cable Wiper Clip (One Piece per Package) | LL3Z-15264B28-A | 2 Req. Reg/Sup Cab

4 Req. Crew Cab | |

| Motorcraft® Low Temperature Grease** | XG-16 | MISC. OTHER | |

| Motorcraft® Door Latch Grease** | XG-13 | ||

| Motorcraft® High Temperature Grease** | XG-11 | ||

| Motorcraft® Silicone Spray** | XL-6 | ||

| Motorcraft® Silicone Sealant** | TA-30 | ||

| Motorcraft® Premium Windshield Wash Concentrate, or a 99 percent Methyl Hydrate (Methanol) product** | ZC-32-B2 | ||

| Cotton Swabs/Q-Tips®** | Obtain Locally | ||

| Isopropyl Alcohol** | |||

| Brushes** | |||

| Syringe, Eye Dropper or a Similar Applicator | |||

| Description | Part Number | Order Quantity | Claim Quantity |

| Interior Door Handle Release Cable (RH Front – All Vehicles Except F-150 with Gas Engine) | HC3Z-15221A00-B | As required **** | |

| Interior Door Handle Release Cable

(LH Front – All Vehicles Except F-150 with Gas Engine) | HC3Z-15221A01-B | ||

| Interior Door Handle Release Cable

(LH/RH Front – Only F-150 with Gas Engine) | FL3Z-15221A00-B | ||

| Interior Door Handle Release Cable

(LH/RH Rear – All Vehicles Crew Cab Doors) | FL3Z-1540180-A | ||

**** Less than 5% vehicles are expected to require a cable replacement.

CERTAIN 2015-2018 MODEL YEAR F-150 AND 2017-2018 MODEL YEAR F-250 – F-550 VEHICLES — DOOR LATCH FREEZING CONCERNS

OVERVIEW

In the affected vehicles, water entering the doors in cold temperatures can cause door latching components to freeze. Ford is offering this no charge service to customers that have experienced a frozen door latch to install additional sealing to the front doors and crew cab rear doors, which will prevent water intrusion and door latch freezing. If an affected vehicle owner has reported a frozen latch concern, dealers are to install additional sealing to the front doors and crew cab rear doors, and lubricate certain door latch, door handle and cable components. This service must be performed at no charge to the vehicle owner.

is offering this no charge service to customers that have experienced a frozen door latch to install additional sealing to the front doors and crew cab rear doors, which will prevent water intrusion and door latch freezing. If an affected vehicle owner has reported a frozen latch concern, dealers are to install additional sealing to the front doors and crew cab rear doors, and lubricate certain door latch, door handle and cable components. This service must be performed at no charge to the vehicle owner.

NOTE: The technical instructions for this program include all additional steps required to also complete safety recall 17S33, if 17S33 is open.

NOTE: Please read this procedure in its entirety, prior to performing repairs. Additionally, instructional videos have been developed to assist with the repair. Please refer to Attachment IV: Instructional Video Links to view the videos.

NOTE: Some of the door foam kits were packaged with incorrect size door glass run funnels. Prior to starting the repair, please refer to ATTACHMENT V – Door Glass Run Funnel Measurement Guide, to ensure the correct funnels are being installed.

SERVICE PROCEDURE

Recommended Tool List:

| General Tools | General Equipment |

| 1/4″ Drive Impact Driver | Flashlight |

| 1/4″ Drive Ratchet | Industrial Grade Heavy Duty Scissors |

| 1/4″ Drive Torque Wrench | Bungee Cords |

| 1/4″ Drive Extension – 6″ (152mm) | Body Tape |

| 1/4″ Drive Socket – 7mm, 8mm and 10mm | Q-Tips® |

| 1/4″ Driver Bit – T-20 and T-25 Torx® | Brushes |

| 3/8″ Drive Ratchet | Caulk Gun |

| 3/8″ Driver Bit – T-30 Torx® | Ruler |

| 3/8″ Drive Torque Wrench | Paint Pen |

| Small Pick | Locally Obtained Syringe, Eye Dropper or Similar Applicator |

| Plastic Trim Removal Tools | Disposable Gloves |

| Pocket Screwdriver | Shop Towel |

| Blowgun | Zip Tie |

| Long Needle Nose Pliers | |

| Utility Knife | |

| 10mm Wrench | |

| Tape Measure |

Front Door Service Procedure

- Is this a F-150 vehicle with safety recall 17S33 open?

Yes – Proceed to the Front Door Latch Water Shield Kit installation Procedure.

No – Proceed to the Front Door and Front Door Latch Sealing Procedure (Page 9).

Front Door Latch Water Shield Kit Installation (Safety Recall 17S33 Open)

NOTE: Front door latch water shields were phased into F-150 production in December 2016.

For vehicles already equipped with water shields, it is not necessary to remove and replace the water shields on the front doors.

NOTE: This procedure uses a different door latch water shield attachment procedure than what was previously used in TSB 16-0155. Do not attempt to use TSB parts to perform this procedure.

NOTE: Procedure to be performed on both front doors.

NOTE: The window must be in the closed (up) position when performing this procedure.

NOTICE: Do not allow the door trim panel or exterior door handle to hang by the door handle cables or damage to the cable and door may occur.

- Remove the exterior front door handles. Please follow the Workshop Manual (WSM) procedures in Section 501-14.

NOTE: The interior grab handle cover clips can be reused for this repair. Only replace if damaged.

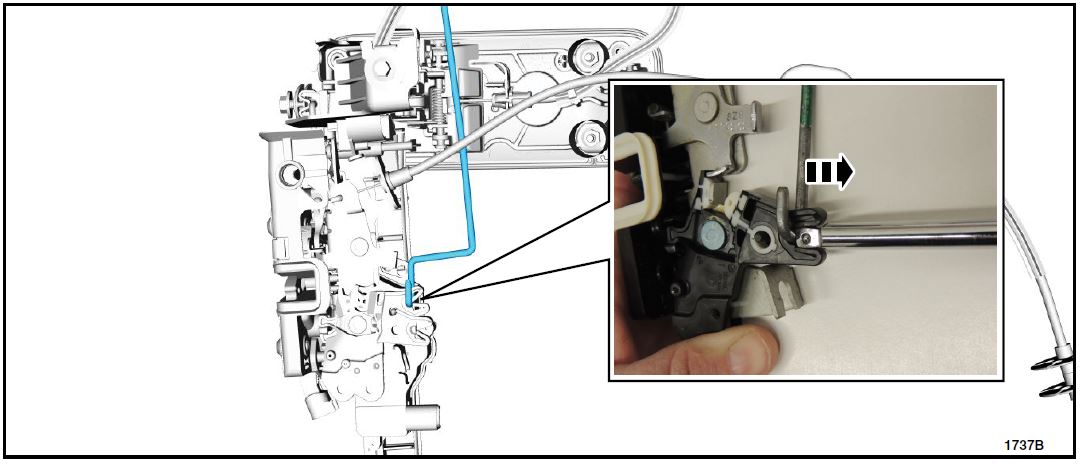

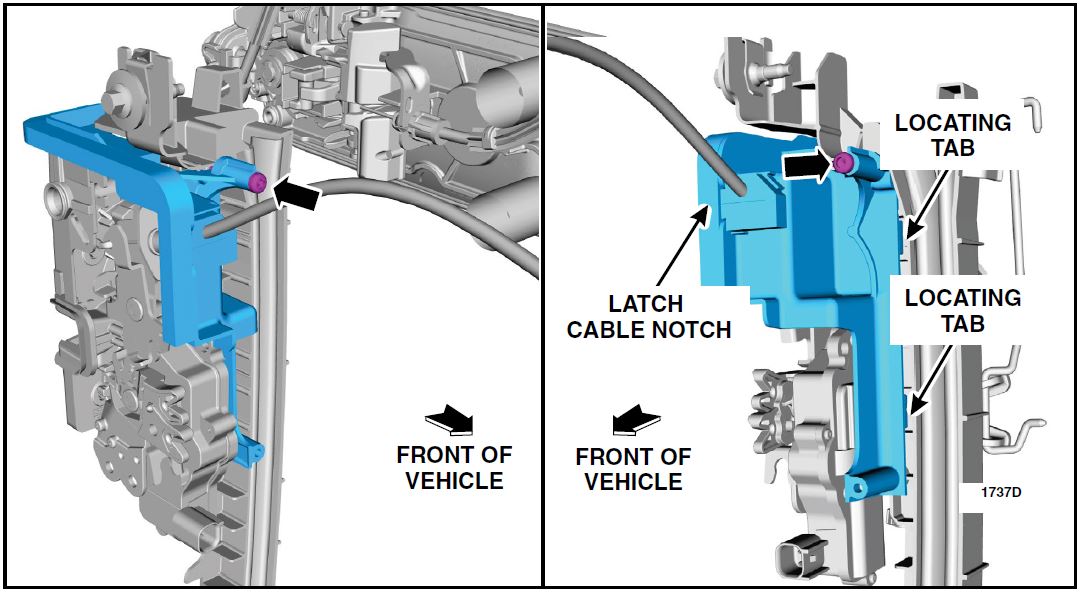

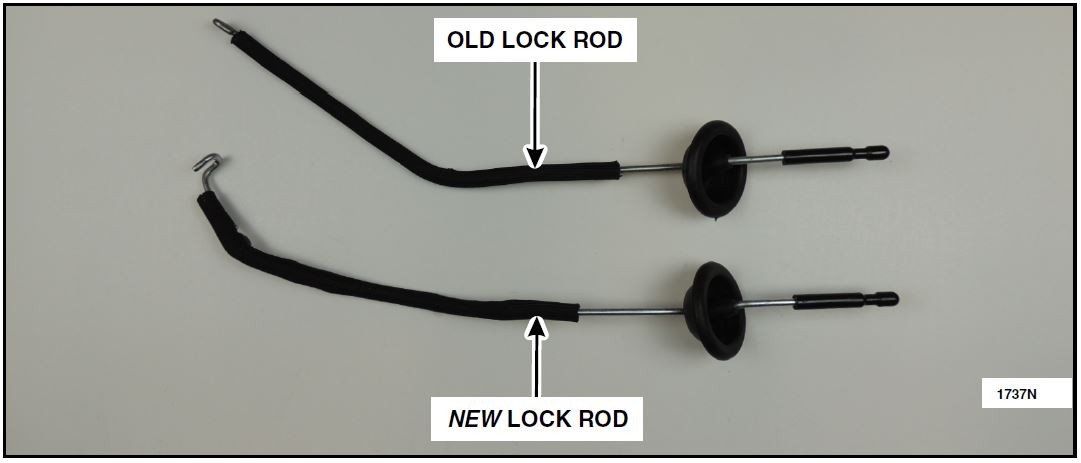

- Remove the lock rod assemblies. See Figure 1.

- Use the male end of a 1/4″ extension to spread apart the lock rod retainer and remove the rod from the door latch.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 1

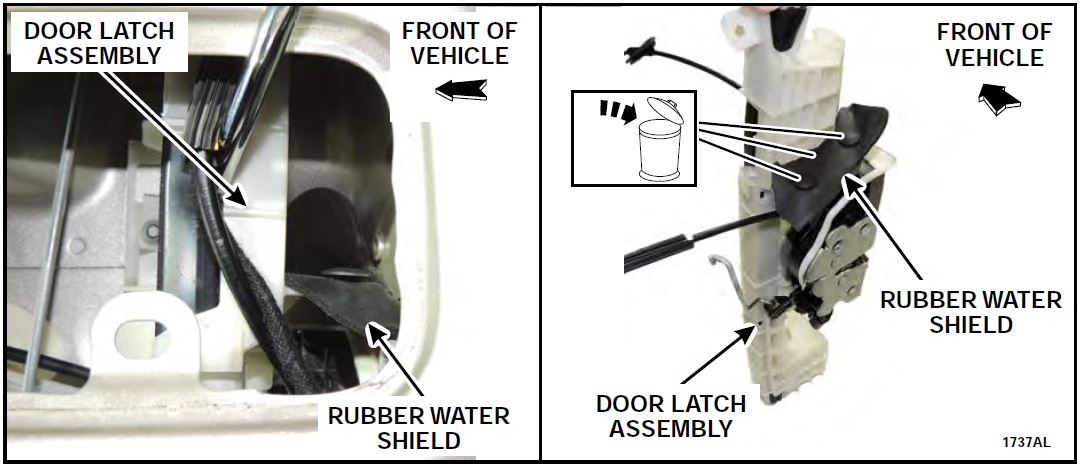

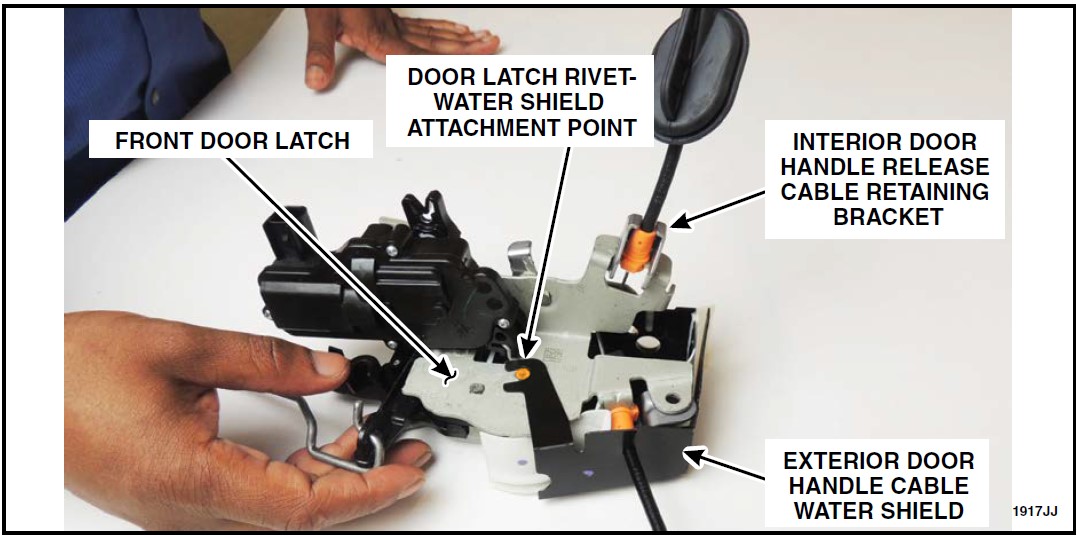

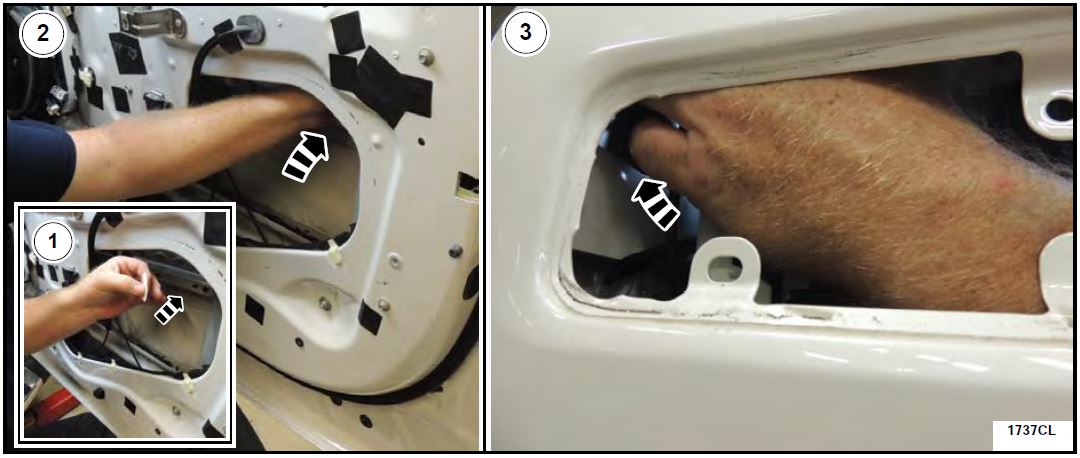

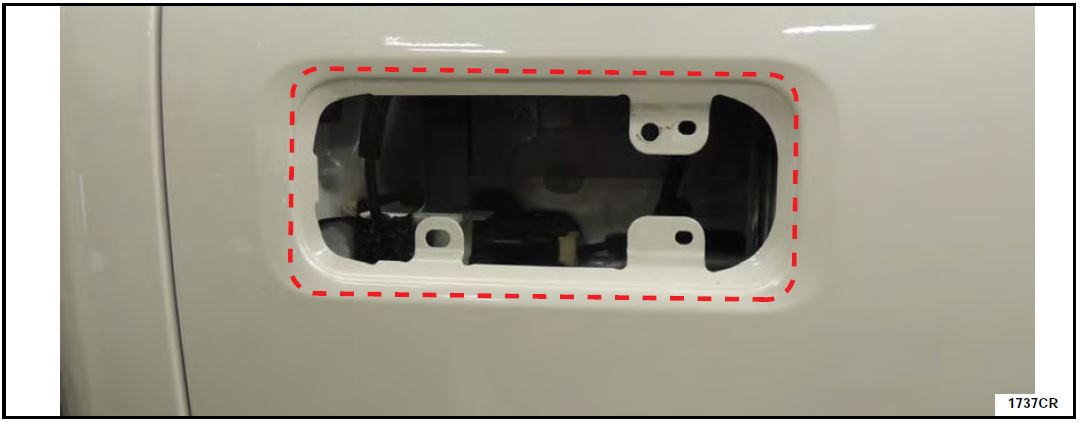

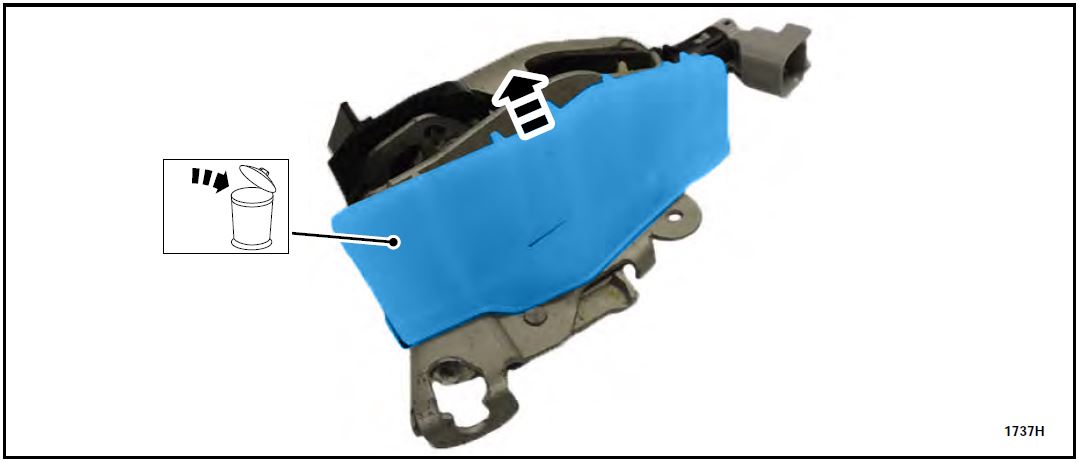

- Through the exterior front door handle opening, inspect for a rubber water shield installed on top of the door latch. See Figure 2.

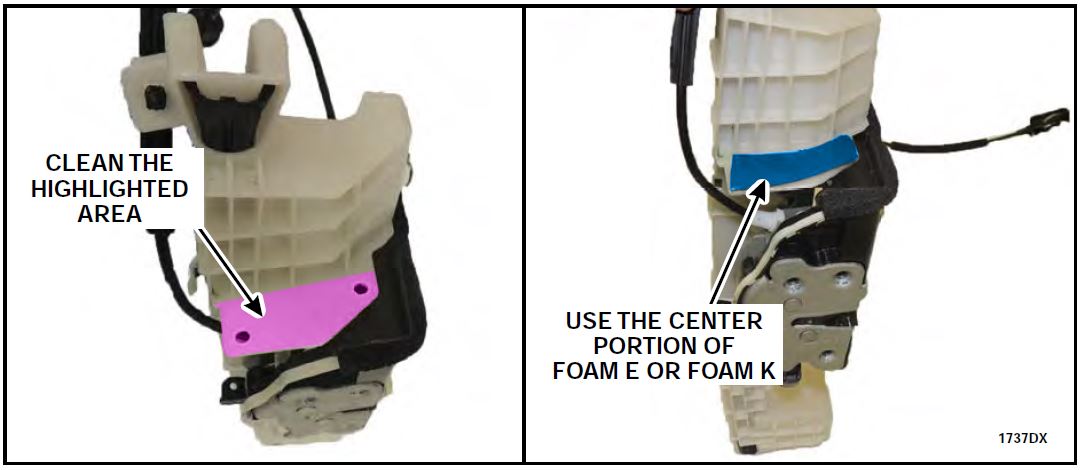

- If a rubber water shield is present, remove and discard the two attaching clips and the rubber water shield.

- Clean the surface area where the water shield covered with isopropyl alcohol and a clean shop cloth. Use part of the center portion of Foam E (refer to Figure 12) or some locally acquired body tape to seal the holes the attaching clips were previously installed in. See Figure 3.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 2

FIGURE 3

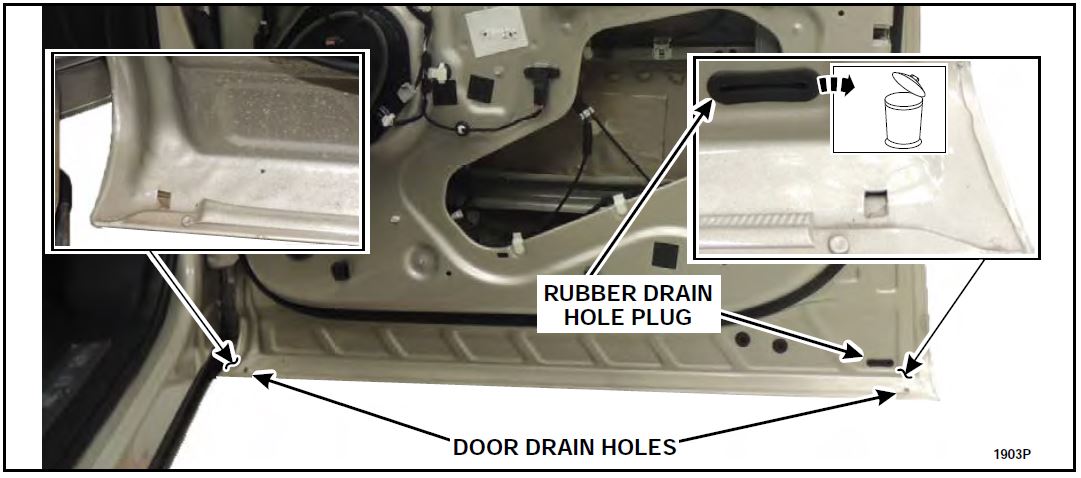

- Remove and discard the rubber drain plug and clean any obstructions, debris, foreign material and residual water from all of the door drain holes using compressed air and a tool such as a plastic trim tool or a zip tie. See Figure 4.

NOTE: Front passenger door shown, all doors similar.

FIGURE 4

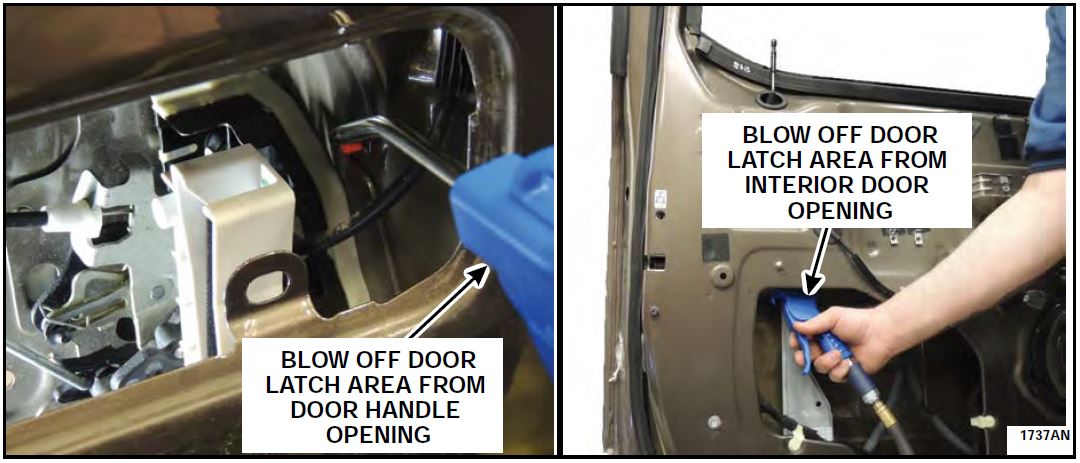

- Using compressed air, blow out any debris or residual water from the door latch assembly, exterior door handle mechanism and cables for thirty seconds. Blow drying with compressed air for thirty seconds is critical to remove as much moisture as possible. See Figure 5.

NOTE: Driver rear door latch shown, all door latches similar.

FIGURE 5

- Loosen but do not remove the two door glass run bolts. See Figure 6.

FIGURE 6

- Loosen but do not remove the 3 door latch bolts. See Figure 7.

FIGURE 7

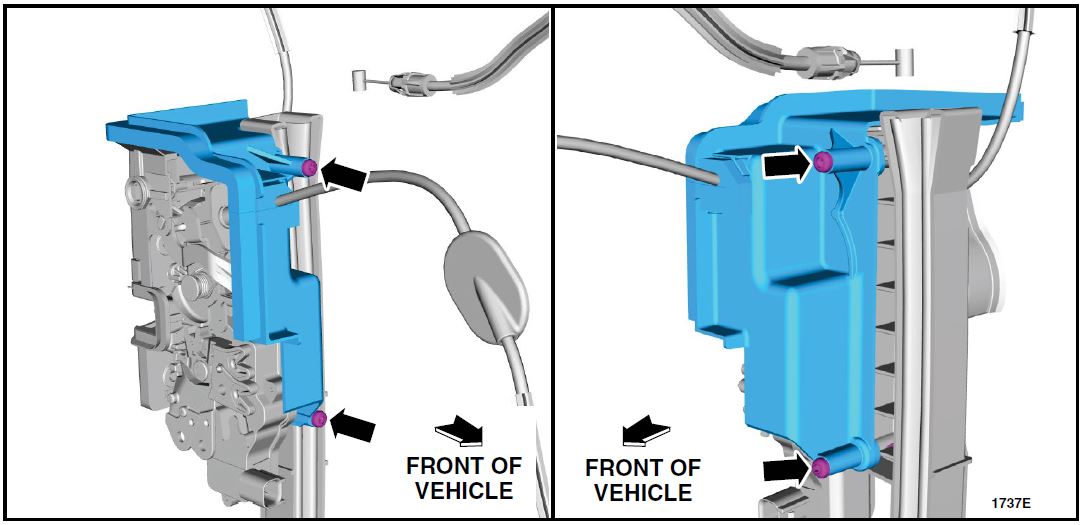

- Apply supplied Foam Tape to the new water shield in the highlighted area. See Figure 8.

FIGURE 8

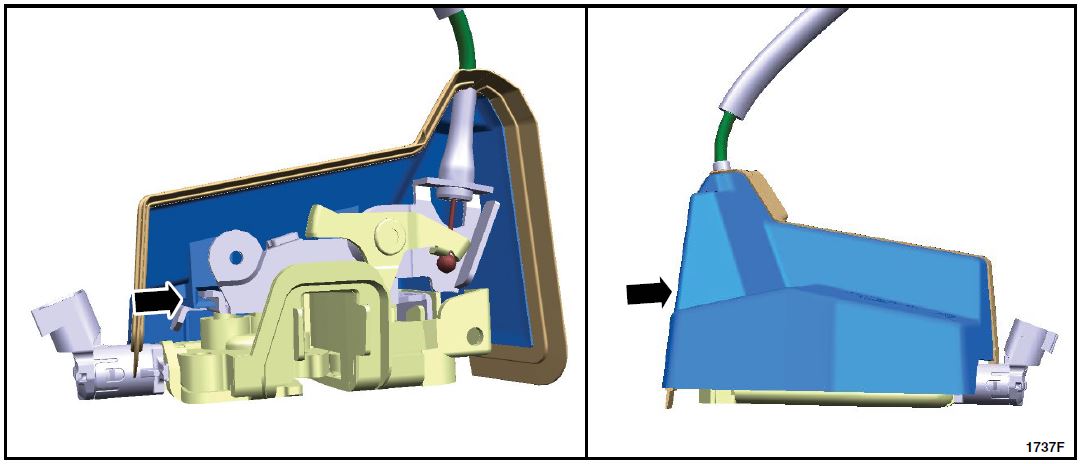

- With the latch and door glass run assembly loose inside the door panel, install the door latch water shield into position. See Figure 9.

NOTE: The water shield is properly installed when the locating tabs align with the door glass run, the latch cable is fitted in the notch of the water shield, and the fastener holes align.

- Install the new screw into the top hole of the shield. See Figure 9.

NOTE: The lower fastener hole of the shield is not used on the front water shields.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 9

- Tighten the two door glass run bolts. See Figure 6.

- 8 Nm (71 lb.in).

- Tighten the three door latch bolts. See Figure 7.

- 8 Nm (71 lb.in).

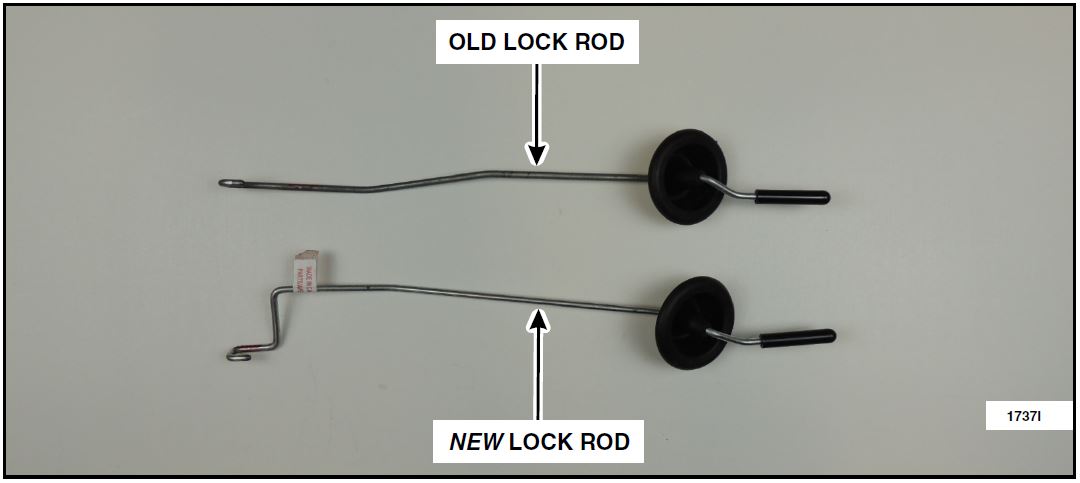

- Refer to Figure 10 to determine if the door latch is equipped with the new style lock rod.

NOTE: The new style lock rod is required to accommodate the water shield.

- Is the door latch equipped with the new style lock rod?

- Yes – Reinstall the lock rod and proceed to the Front Door and Front Door Latch Sealing

Procedure (Page 9). - No – Proceed to Step 17.

- Yes – Reinstall the lock rod and proceed to the Front Door and Front Door Latch Sealing

FIGURE 10

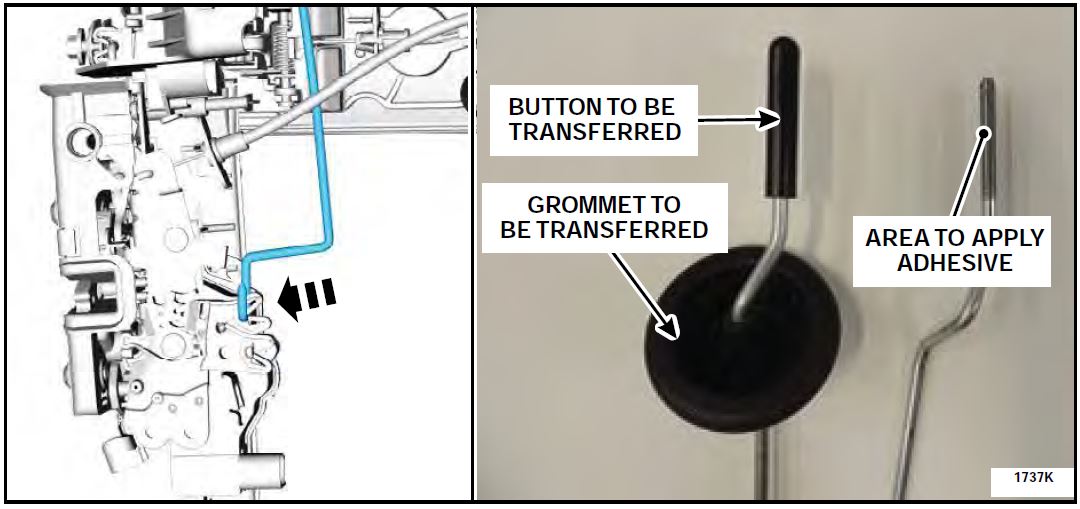

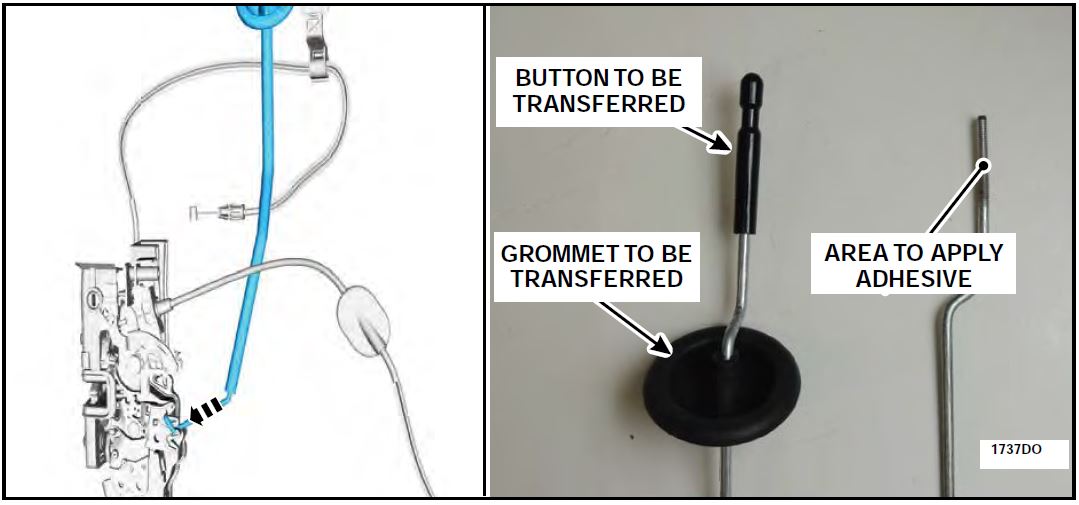

NOTE: If a replacement lock rod already has a button and grommet installed, transfer of the components is not required.

- Replace the lock rod and transfer the necessary components. See Figure 11.

a. Transfer the grommet and button from the original lock rod to the new lock rod.

b. Apply a bead of Motorcraft® Instant Gel Adhesive TA-19-C or equivalent to the lock rod prior to threading the button onto the new lock rod.

c. When threading the button onto the new lock rod, stop threading when some resistance is met.

d. Ensure both front lock rod buttons are installed at similar heights.

e. Reinstall the lock rod.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 11

- Proceed to the Front Door and Front Door Latch Sealing Procedure.

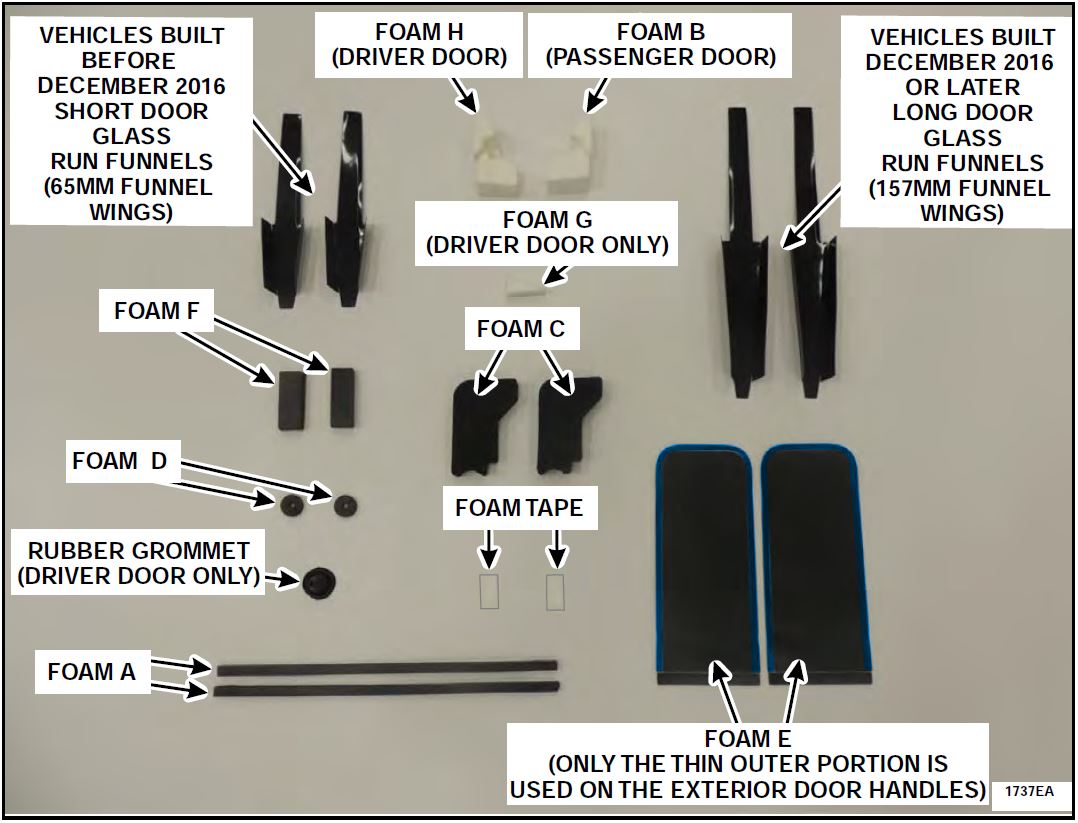

Front Door and Front Door Latch Sealing Procedure

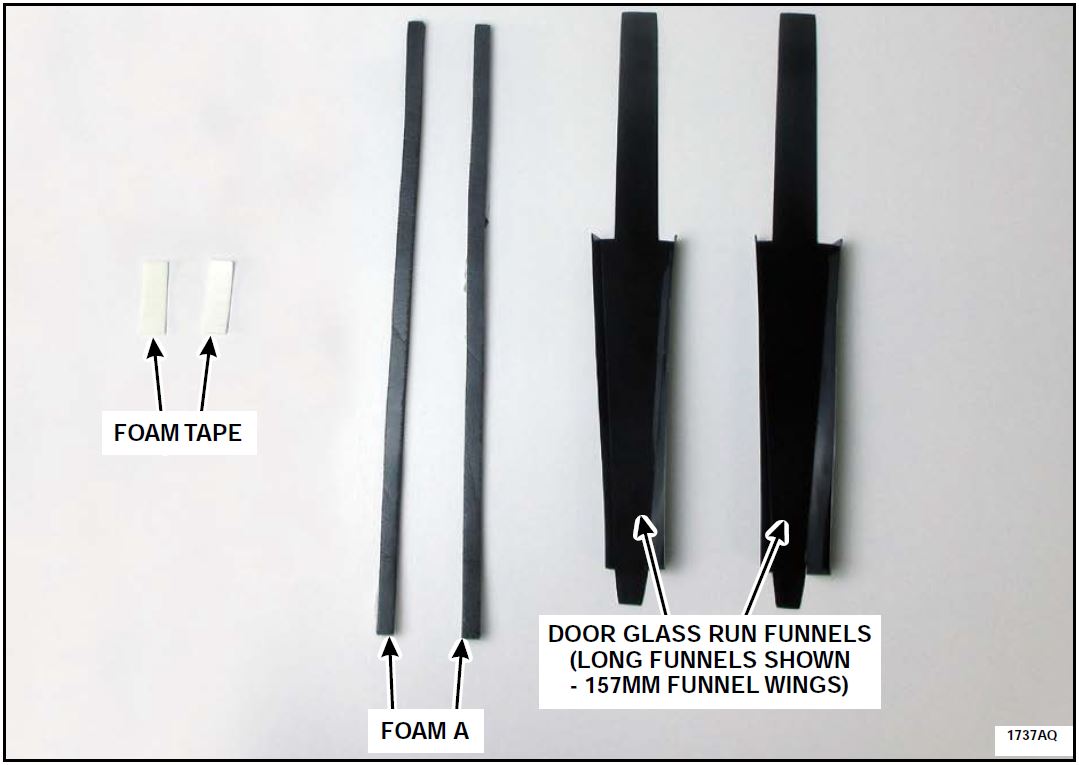

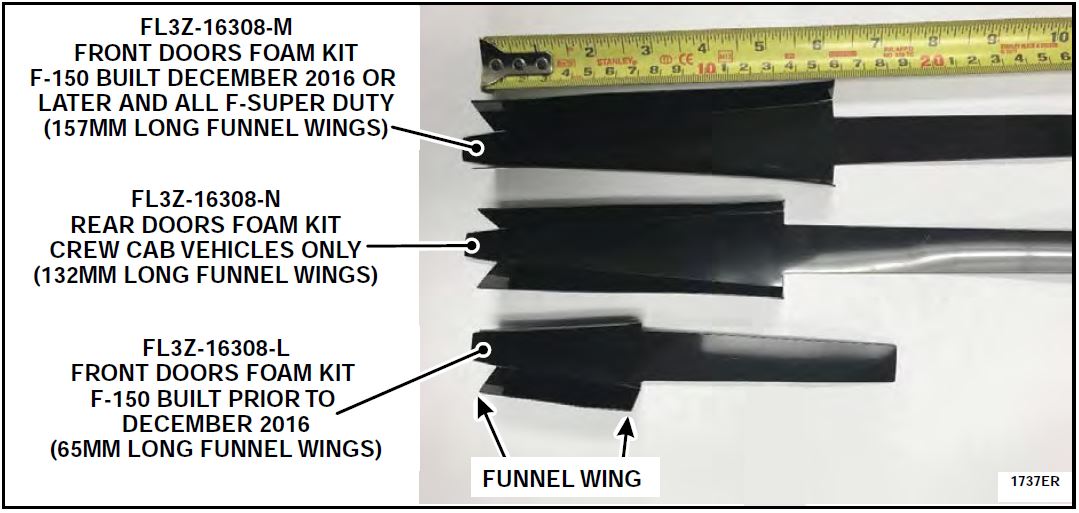

IMPORTANT! There are two different front door foam kits available for the F-150 vehicles. One kit comes with short (65mm funnel wings) door glass funnels (built before December 2016), and the other kit comes with long (157mm funnel wings) door glass funnels (built December 2016 or later). Funnel usage is based on vehicle build date and the length of the door glass run installed. Only one front door foam kit is available for the F-250-F-550 vehicles and the kit contains long (157mm funnel wings) door glass funnels. Refer to Attachment V for additional information.

NOTE: Procedure to be performed on both front doors.

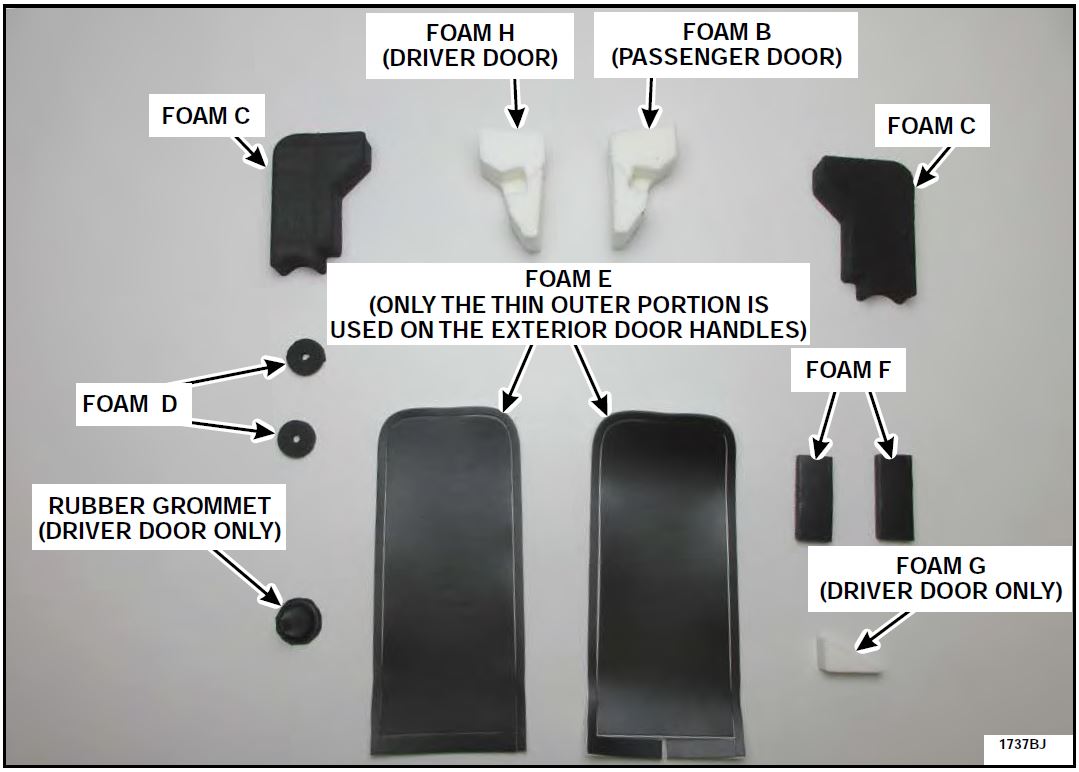

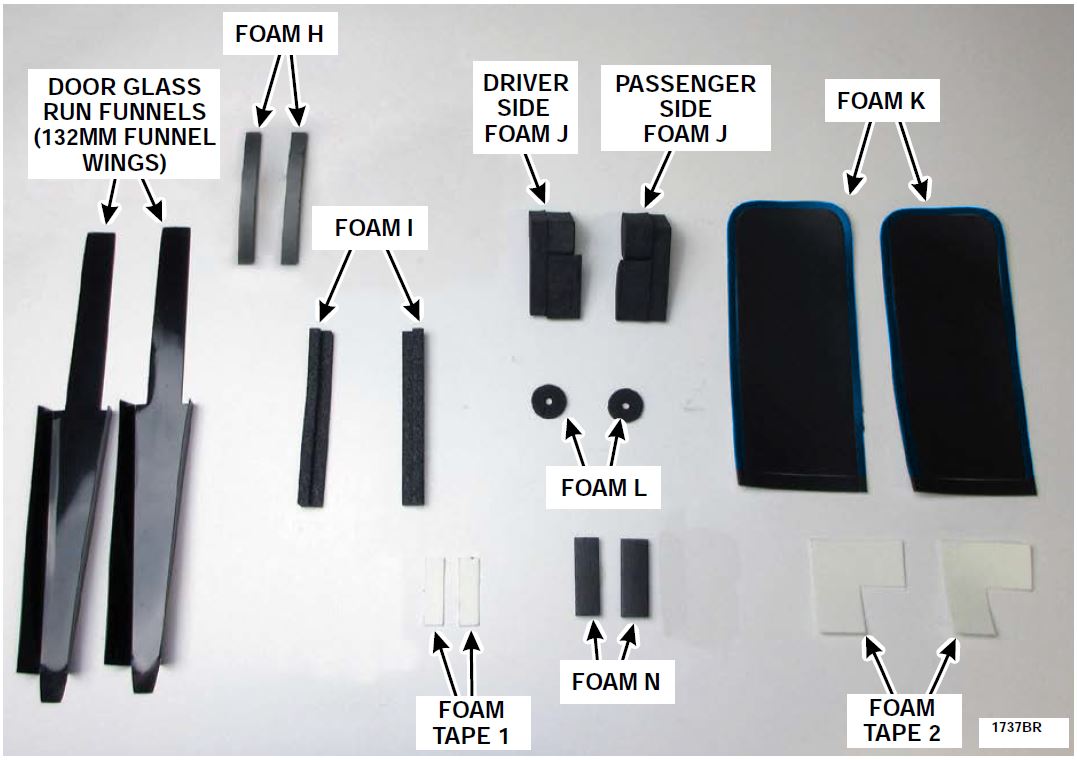

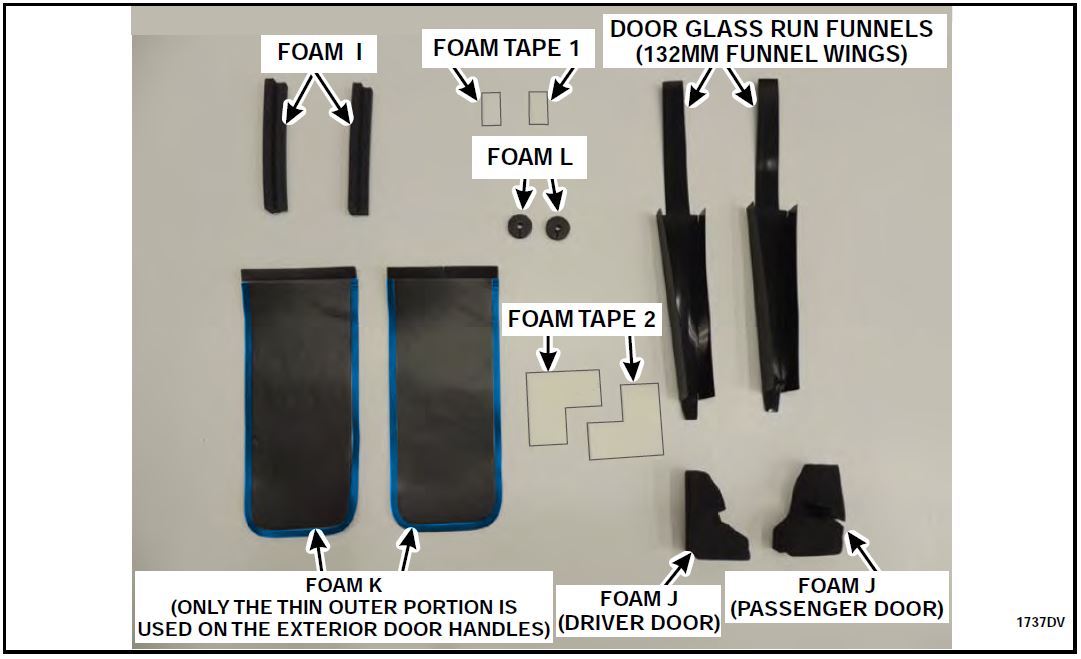

Complete Front Door Part Kit – Each Kit Will Include Either Long Door Glass Run Funnels Or Short Door Glass Run Funnels

FIGURE 12

NOTE: The parts being installed in this procedure are not labeled. Refer to Figure 12 for component identification.

NOTE: These components will be used for the following procedures:

- Front Door Glass Run and Belt Moulding Sealing Procedure (All Vehicles)

- Front Door Latch and Handle Service Procedure (All Vehicles)

Front Door Glass Run and Belt Moulding Sealing Procedure (All Vehicles)

Front Door Glass Run and Belt Moulding Sealing Components

FIGURE 13

NOTE: Procedure to be performed on both front doors.

NOTE: The window must be in the closed (up) position when performing this procedure.

NOTICE: Do not allow the door trim panel or exterior door handle to hang by the door handle

cables or damage to the cable and door may occur.

- Remove the exterior front door handles. Please follow the Workshop Manual (WSM) procedures in Section 501-14.

NOTE: The interior grab handle cover clips can be reused for this repair. Only replace if damaged.

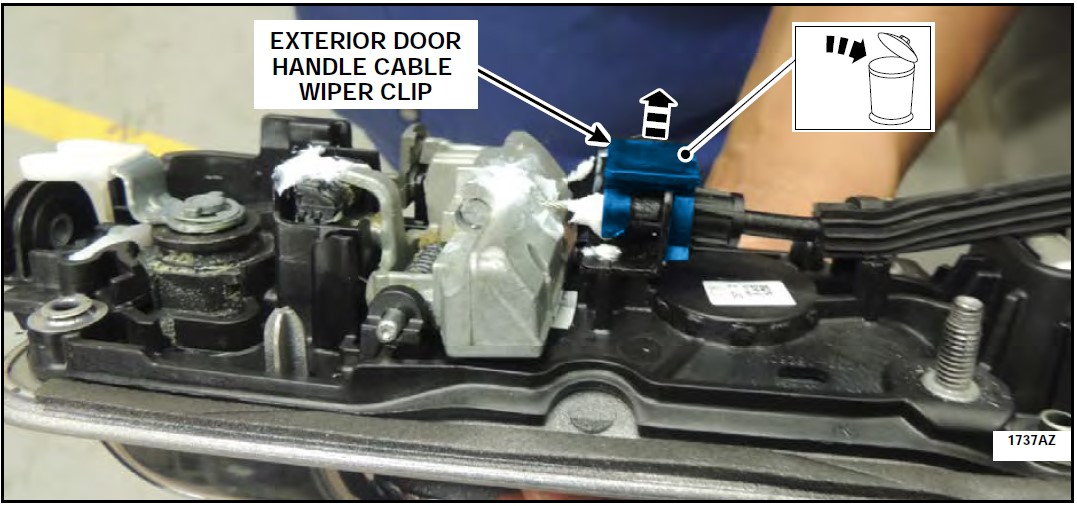

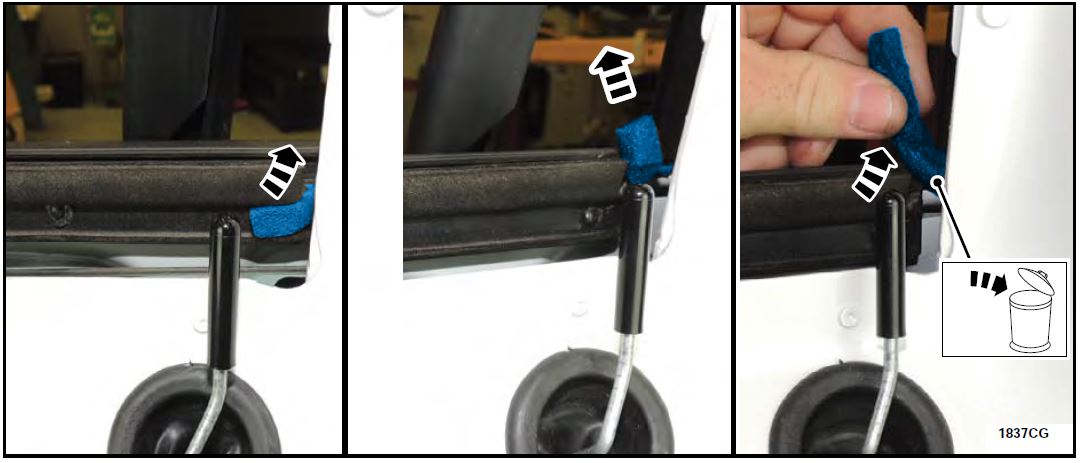

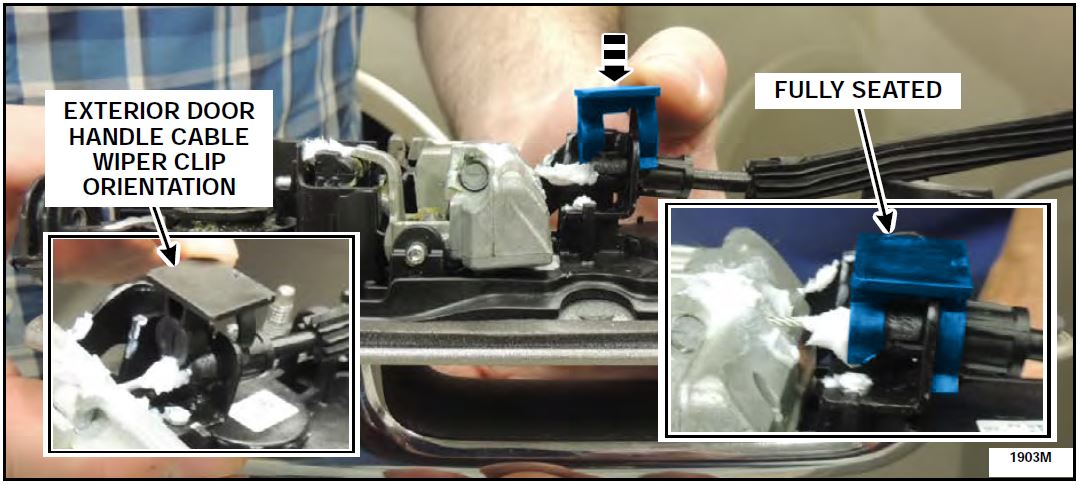

- If a cable wiper clip is present on the exterior door handle cable end, remove and discard the cable wiper clip. See Figure 14.

FIGURE 14

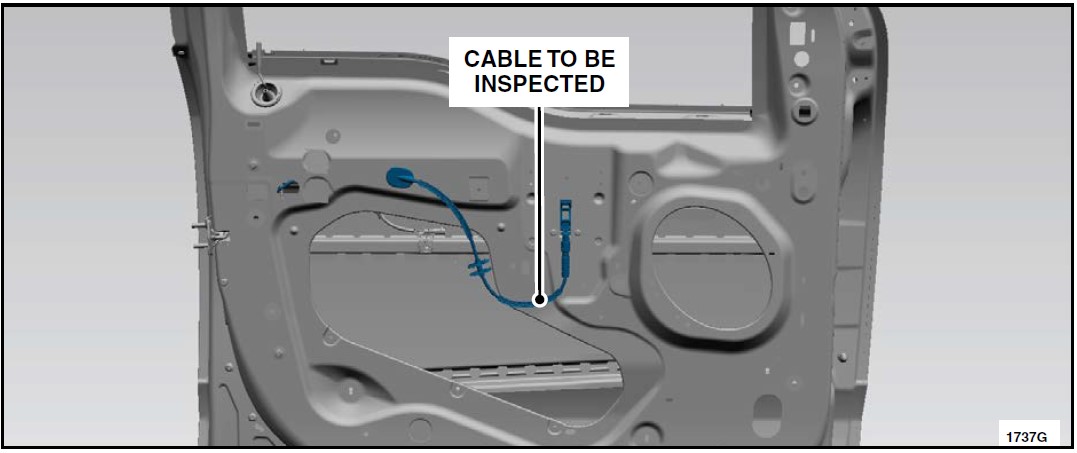

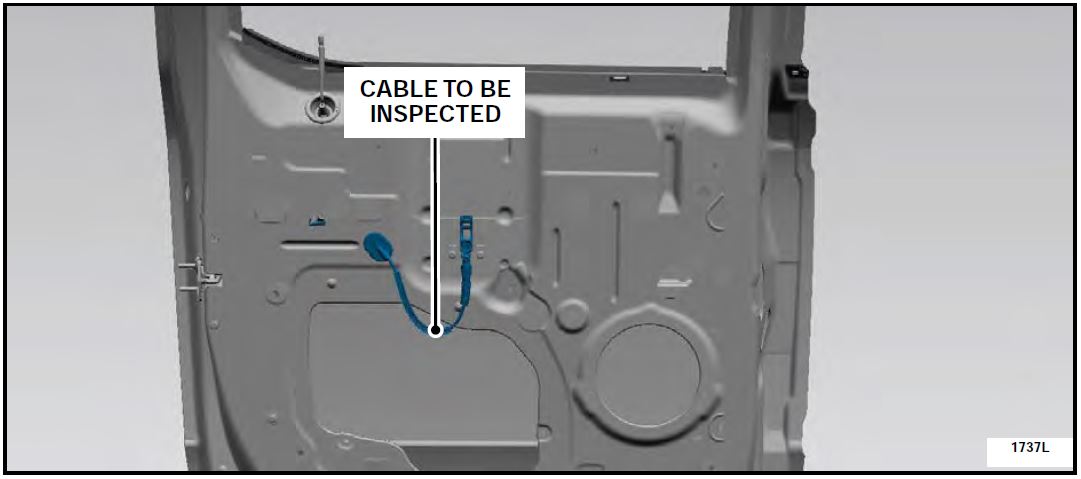

- Inspect the interior door handle to latch release cable for kinking. See Figure 15.

– Were any kinks visible on the interior door handle release cable?

Yes – Continue to Step 4.

No – Proceed to Step 6.

FIGURE 15

NOTE: The front door latch of some vehicles is equipped with a small flexible plastic water shield located over the exterior door handle cable attachment point. Note the water shield position and orientation for reassembly. See Figure 16.

NOTE: Certain vehicles are equipped with an interior door handle release cable retaining bracket on the front door latch. The interior door handle release cable is serviced in a similar manner whether or not a cable retaining bracket is present. See Figure 16.

FIGURE 16

NOTE: It is not necessary to detach the exterior door handle cable from the retaining bracket or remove the exterior door handle cable from the latch.

- Remove the front door latch and install a new interior door handle release cable. Please follow the WSM procedures in Section 501-14.

CAUTION: Use caution not to kink the cables during reassembly of the door latch. NOTE: Do not reinstall the door panel, watershield or the exterior door handle at this time.

- Reassemble and reinstall the front door latch. Complete by reversing the WSM procedures in Section 501-14. Then proceed to Step 6.

- If water shield kit installation was not necessary, remove and discard the rubber drain plug and clean any obstructions, debris, foreign material and residual water from all of the door drain holes using compressed air and a plastic trim tool. See Figure 17.

NOTE: Front passenger door shown, all doors similar.

FIGURE 17

- If not previously performed, use compressed air and blow out any debris or residual water from the door latch assembly, exterior door handle mechanism and cables for thirty seconds. Blow drying with compressed air for thirty seconds is critical to remove as much moisture as possible. See Figure 18.

NOTE: Driver rear door latch shown, all door latches similar.

FIGURE 18

- Position the front door window glass down.

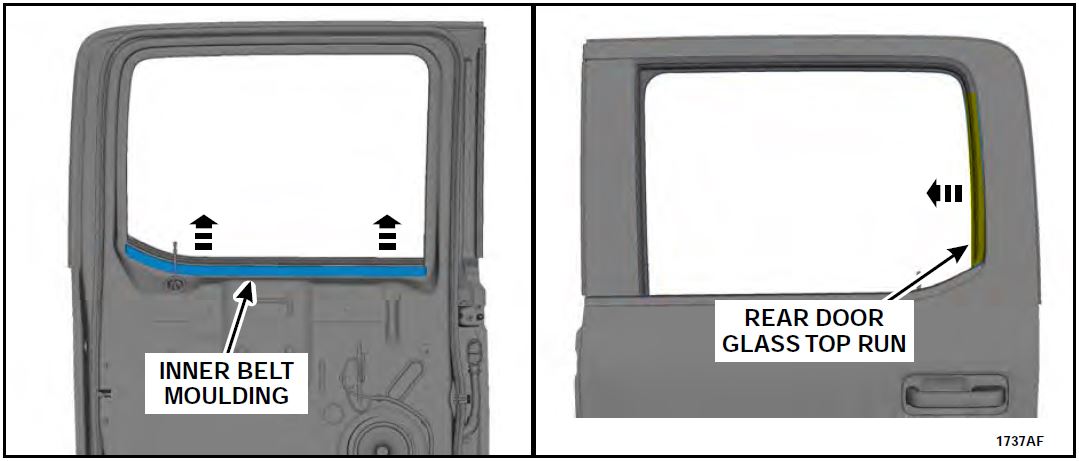

- Remove the inner belt moulding and position aside the latch side of the door glass top run.

See Figure 19.

FIGURE 19

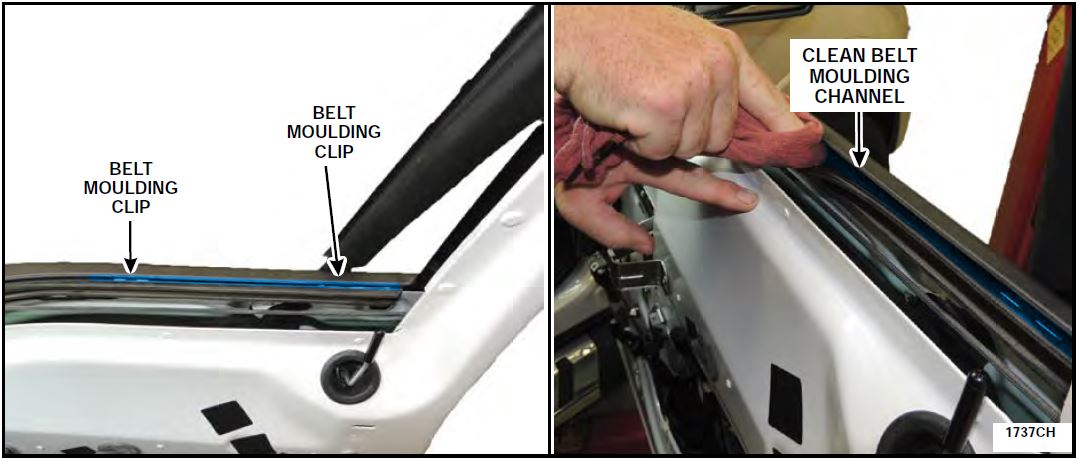

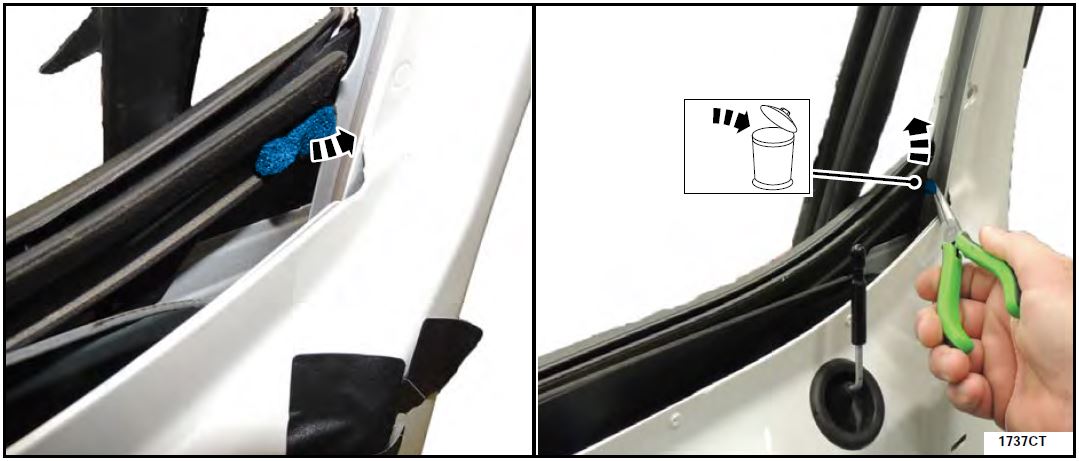

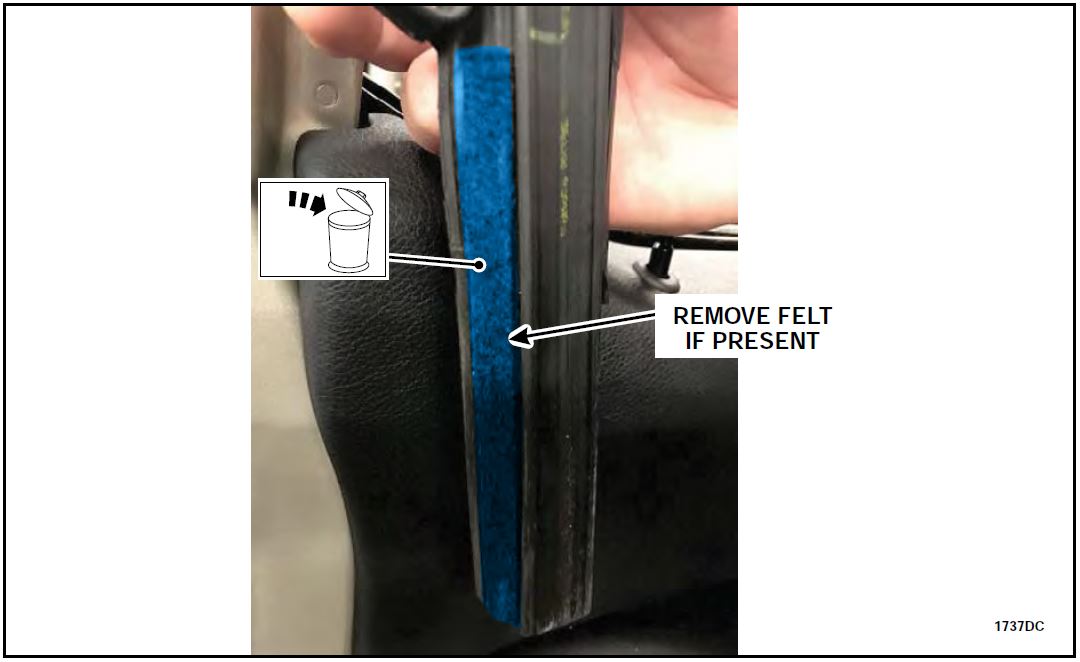

- If present, remove and discard existing foam on the driver and passenger side outer belt moulding (also known as upper belt moulding) at this location. See Figure 20.

NOTE: Passenger door shown, driver door similar.

FIGURE 20

- Clean the highlighted area of the outer belt moulding with isopropyl alcohol and a clean shop cloth.

See Figure 21.

FIGURE 21

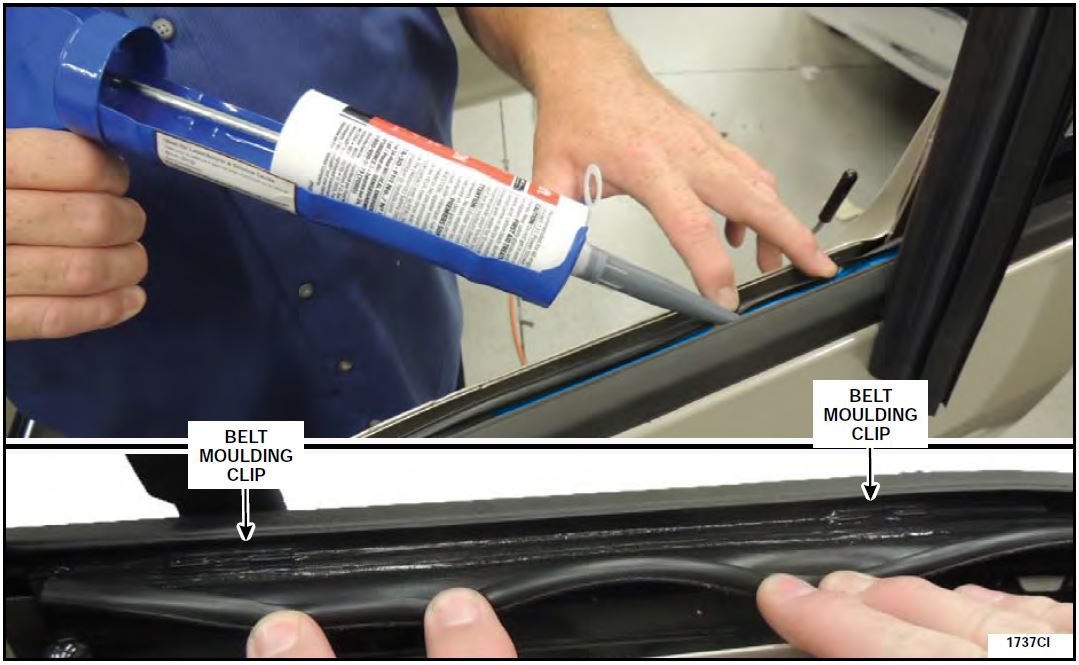

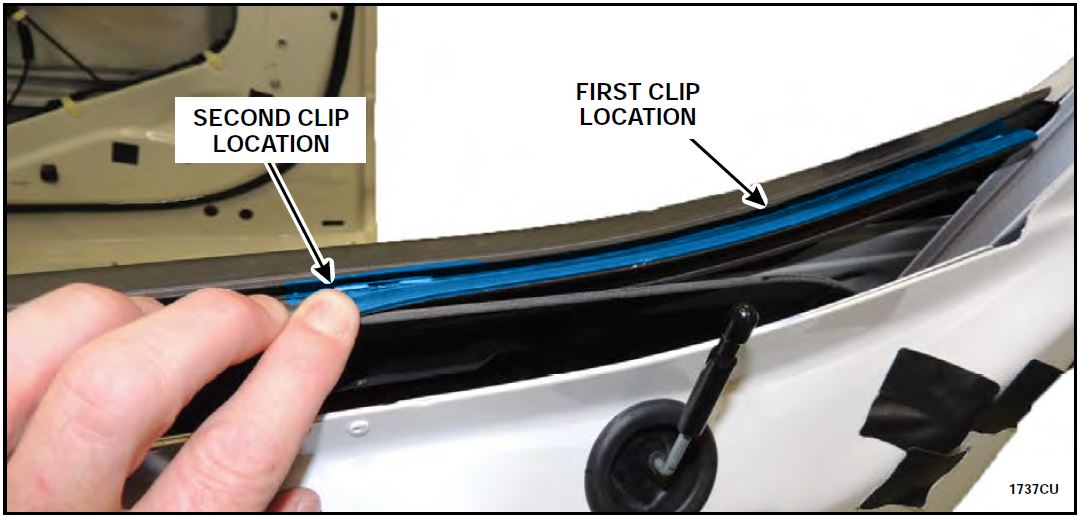

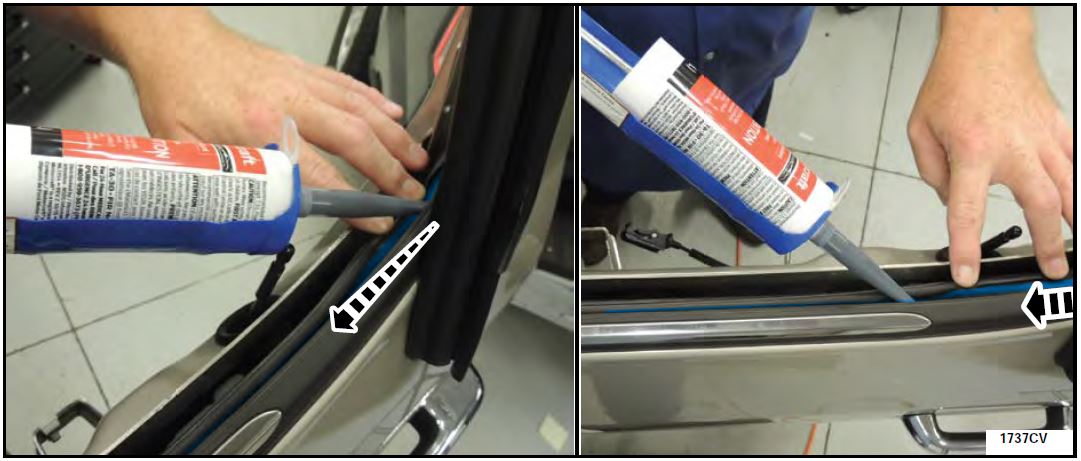

- Apply a small bead of Motorcraft® TA-30 Silicone sealant onto the highlighted area of the outer belt moulding, ensuring the two belt moulding clips shown in Figures 21 and 22 are completely covered. Using your finger, smooth out the sealer to establish an even surface. See Figure 22.

NOTE: A proper seal around the belt moulding metal clips is necessary to prevent water from entering the door.

FIGURE 22

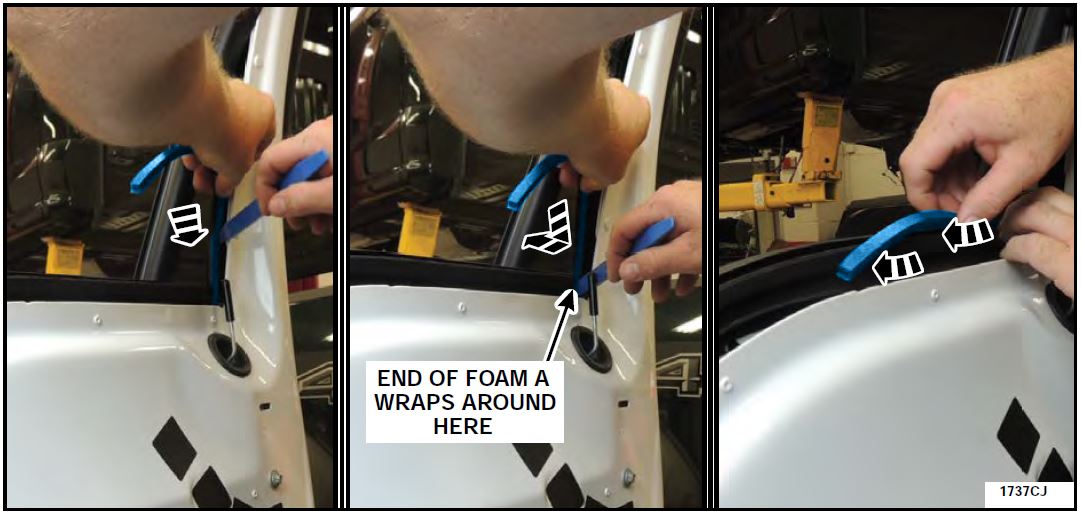

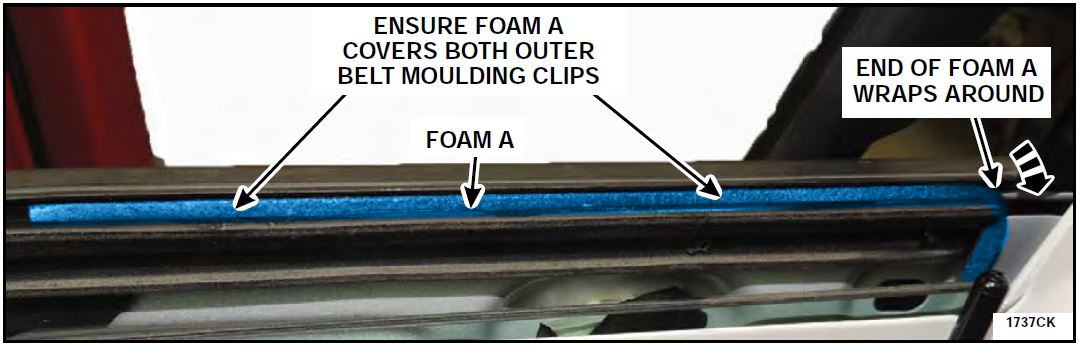

- Using a small trim removal tool, install Foam A to the outer belt moulding on top of the bead of silicone that was previously applied. Both of the outer belt moulding clips need to be covered by the Foam A. See Figures 23 and 23.

NOTE: It is crucial that both outer belt moulding clips are covered by Foam A and that the end of Foam A wraps around the outer belt moulding as shown.

FIGURE 22

FIGURE 24

- Remove any excessive silicone in visible areas on the outer belt moulding with isopropyl alcohol and a clean shop cloth.

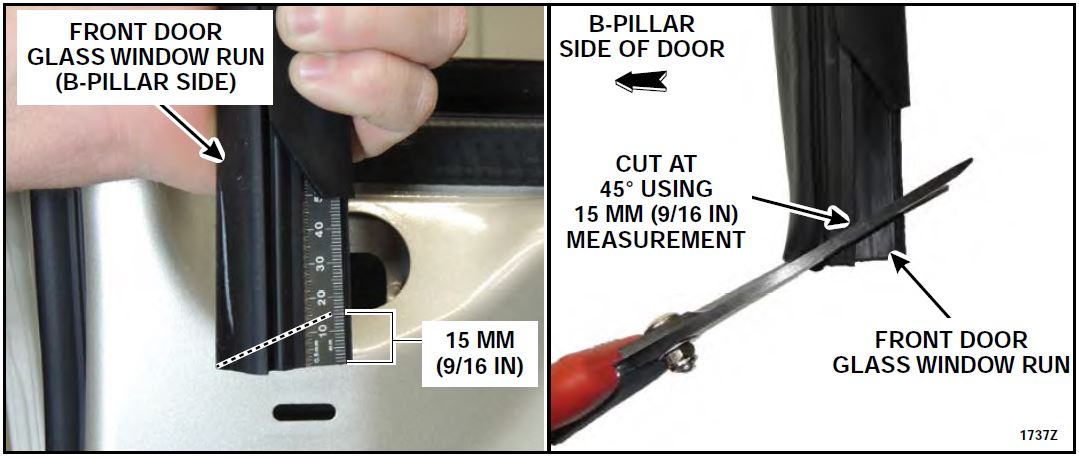

- Modify the front door glass top run. See Figure 25.

a. Measure 15 mm (9/16 in) from the inboard bottom corner of the door glass top run.

b. Mark the 15 mm (9/16 in) location.

c. Starting at the bottom outboard corner of the door glass top run, cut a 45° notch using the previous measurement as a guide.

FIGURE 25

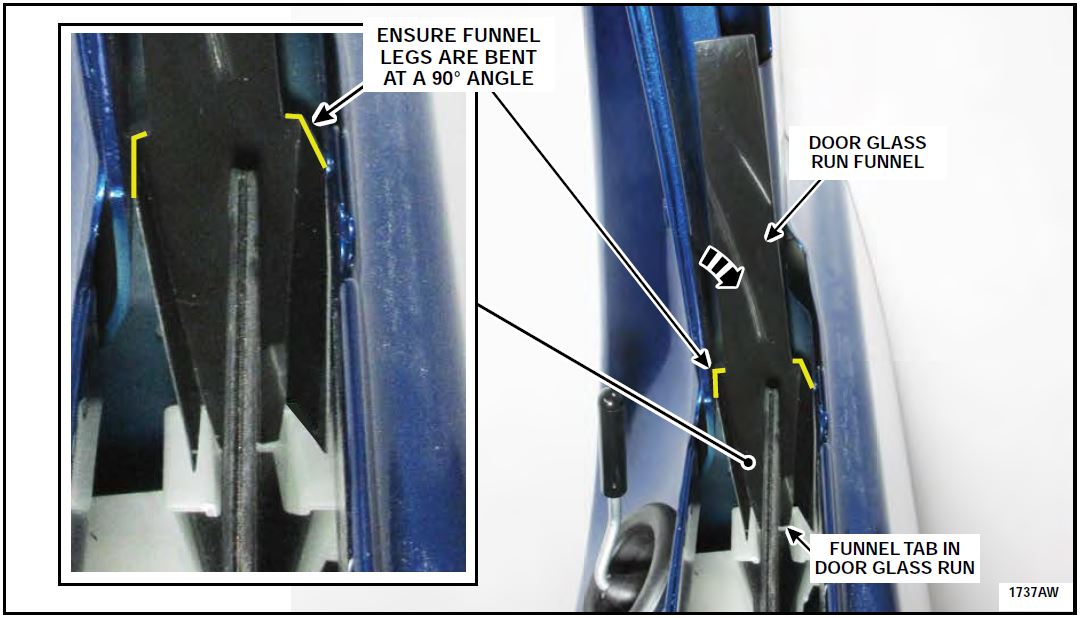

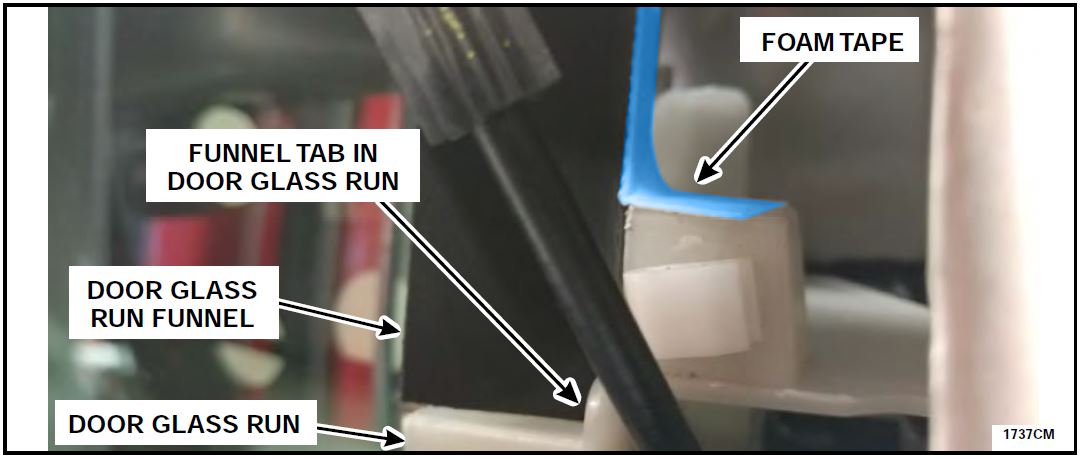

- Install one of the appropriate length door glass run funnels ensuring that the lower tab is situated in the door glass run and the funnel sides sit at a 90° angle above the door glass run. See Figure 26. Refer to Attachment V for additional information.

- F-150 vehicles: Short funnels – 65mm funnel wings (built before December 2016), Long funnels

– 157mm funnel wings (built December 2016 or later) - F-250-F-550 vehicles: Long funnels only – 157mm funnel wings

- F-150 vehicles: Short funnels – 65mm funnel wings (built before December 2016), Long funnels

NOTE: Ensure the funnel sides are at a 90° angle upon installation. It may be necessary to bend the sides of the funnel back to a 90° angle before installation.

FIGURE 26

- Reinstall the latch side of the front door glass top run and the inner belt moulding. See Figure 19.

NOTICE: IT WILL BE NECESSARY TO HOLD THE UPPER PORTION OF THE FUNNEL WHEN INSTALLING THE DOOR GLASS TOP RUN. CARE MUST BE TAKEN TO NOT BEND OR DAMAGE THE DOOR GLASS RUN FUNNEL.

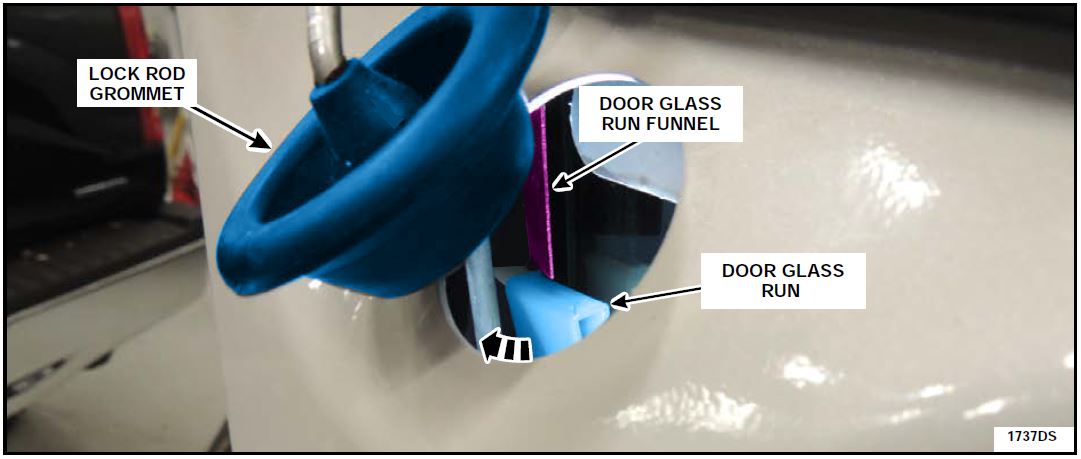

- Unseat the front door lock rod grommet and visually confirm that the funnel is in the correct position and then reinstall the front door lock rod grommet. See Figure 27.

NOTE: Driver door lock rod grommet shown, passenger door lock rod grommet similar.

FIGURE 27

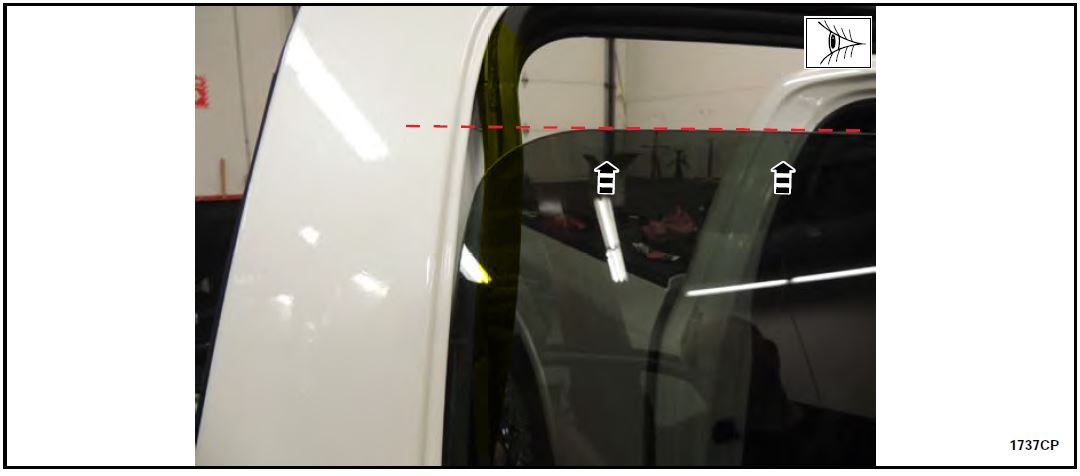

- Raise the front door window to the full up position.

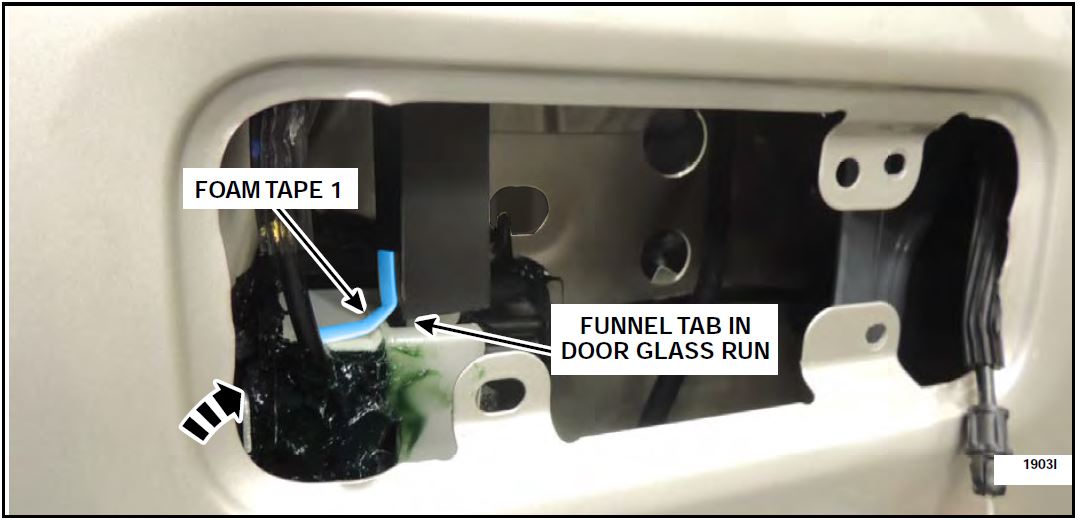

- Using your hand install the Foam Tape on the top of the door glass run and on the back of the door glass run funnel in the order shown in Figure 28. Figure 29 shows the Foam Tape installed.

FIGURE 28

NOTE: Front door shown, rear door similar.

FIGURE 29

- Using isopropyl alcohol clean the top portion of the door and then neatly apply Motorcraft® TA-30 silicone sealant to the indicated/highlighted area in order to completely fill the gap as shown in Figure 30.

- Do not close the door until the silicone is cured.

NOTE: Proper application of the sealant is crucial to properly water seal the door and also avoid appearance concerns.

NOTE: Top of driver front door shown, passenger front door similar.

FIGURE 30

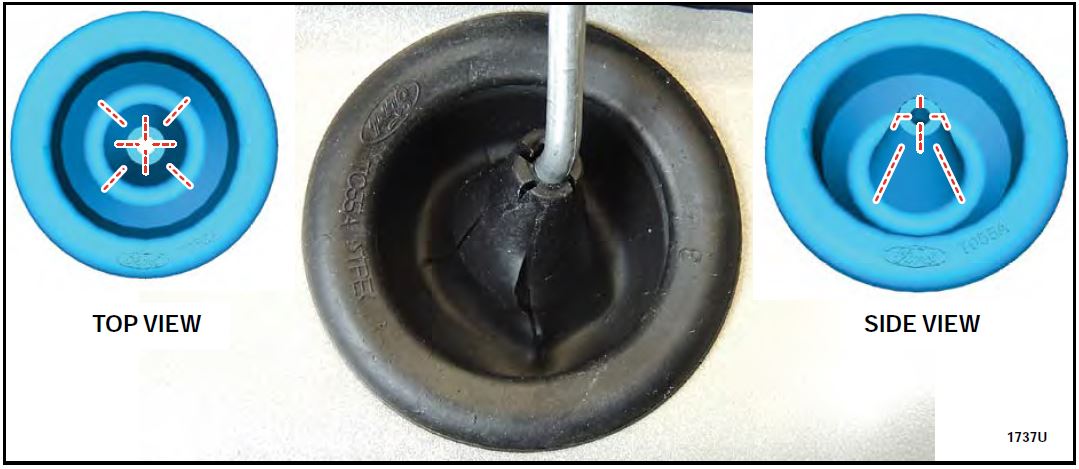

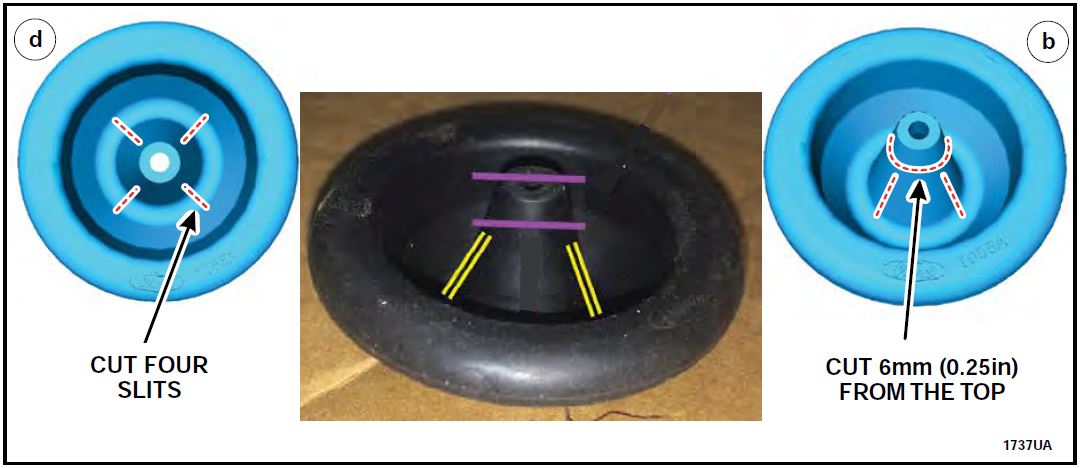

- Modify the front door lock rod grommet. See Figure 31.

a. Using a utility knife, cut four 6 mm (.25 in) long slits approximately 90° apart into the top of the front door lock rod grommet where the lock rod exits the grommet.

b. Cut four additional 13 mm (.5 in) long slits approximately 90° apart on the inner sides of the grommet 45° separated from the previously cut slits.

FIGURE 31

- Proceed to the Front Door Latch and Exterior Handle Service Procedure.

Front Door Latch and Exterior Handle Service Procedure (All Vehicles)

NOTE: Procedure to be performed on both front doors.

Front Door Latch and Exterior Handle Sealing Components

FIGURE 32

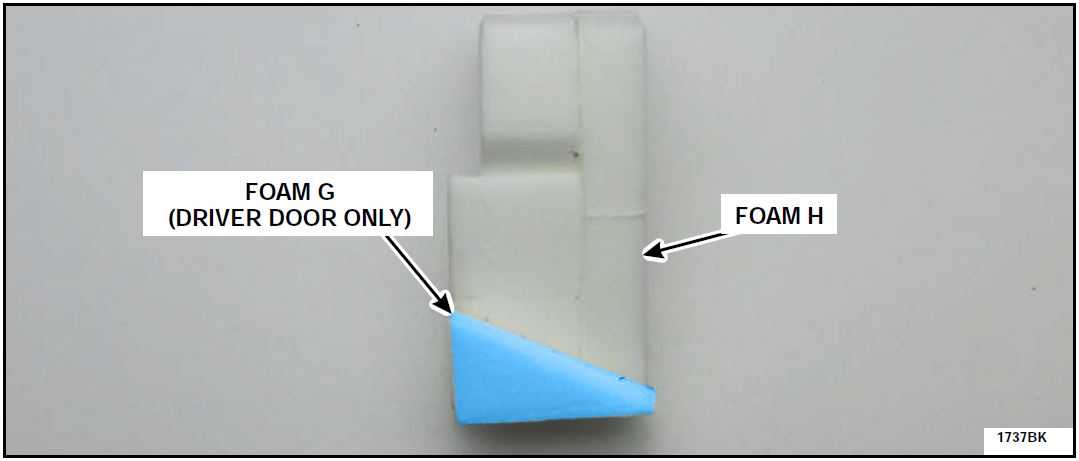

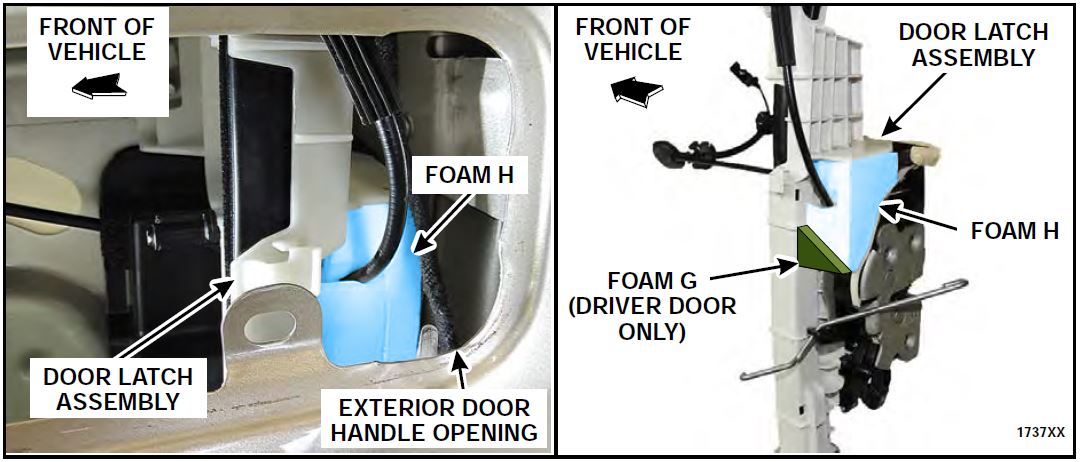

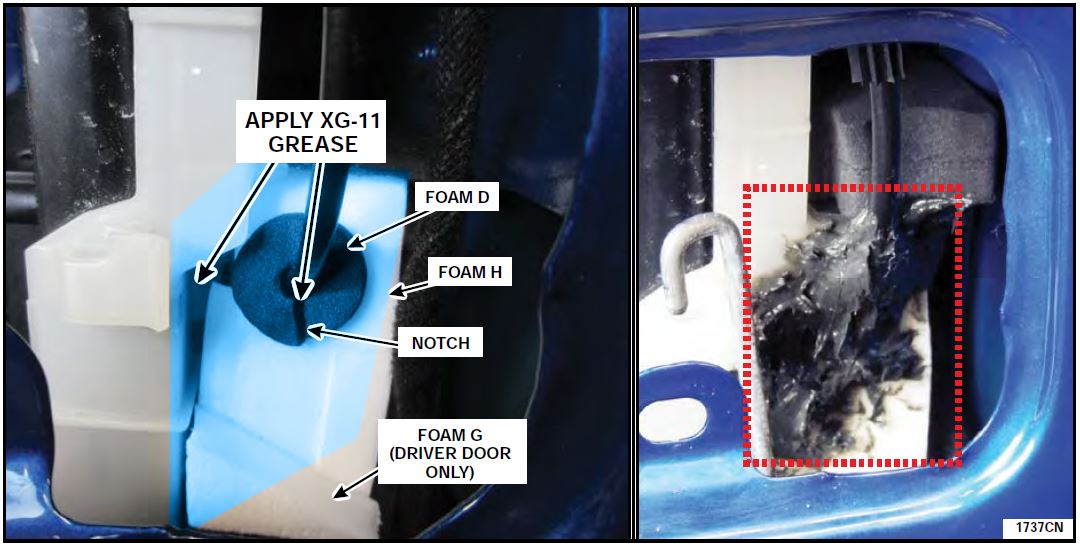

- For driver door latch only, attach Foam G to Foam H. See Figure 33.

FIGURE 33

- Install Foam H onto the driver door latch. See Figure 34.

NOTE: Driver door latch shown with Foam G and H, Passenger door latch similar with Foam B.

FIGURE 34

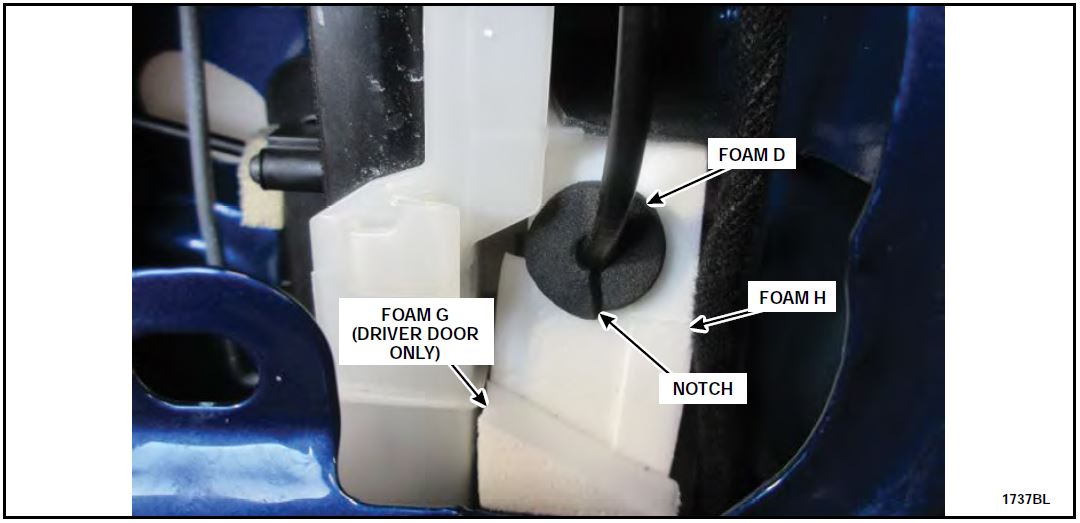

- Install Foam D over the door latch cable and onto Foam H (driver door) and Foam B (passenger door) to cover the gap between the cable and Foam H. See Figure 35.

- The notch of Foam D must point downwards when installed.

NOTE: Driver door latch shown with Foam G and H, Passenger door latch similar with Foam B.

FIGURE 35

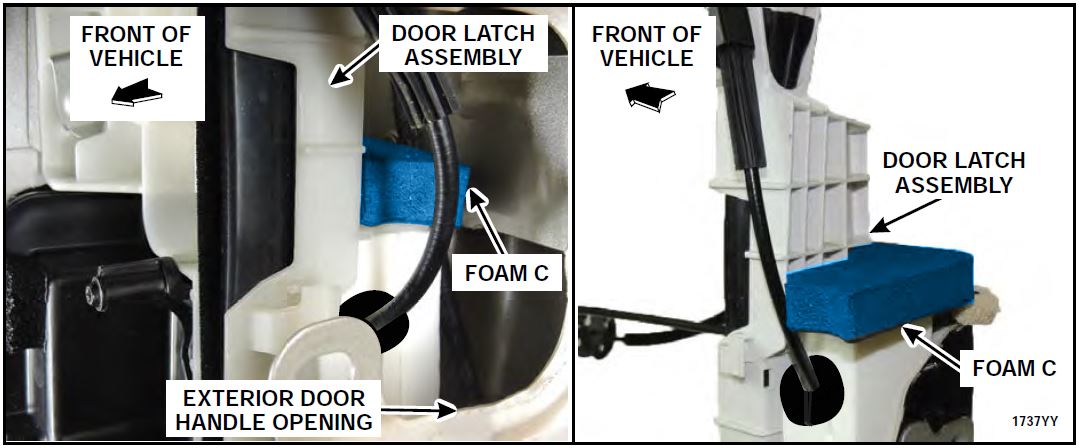

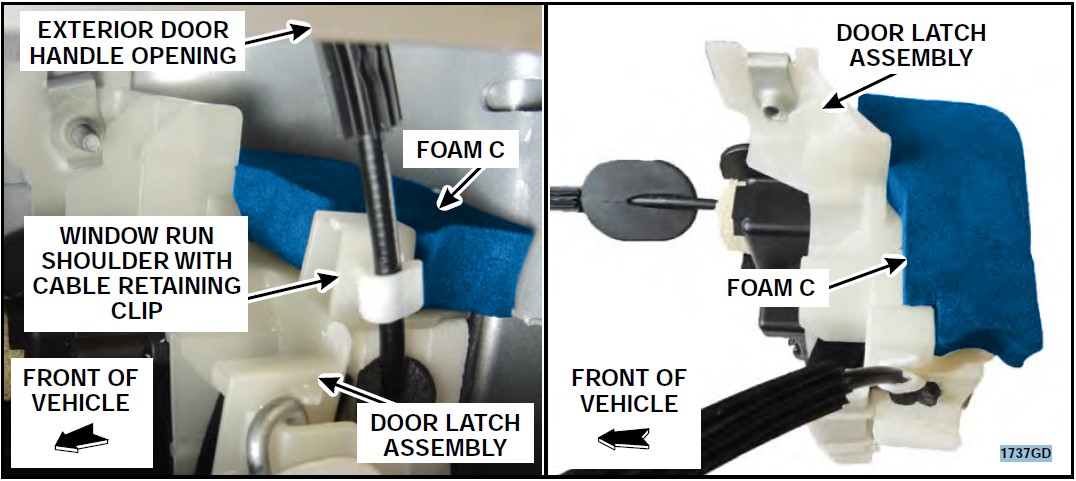

- Using a trim tool, install Foam C onto the top of the front door latch water shield.

NOTE: For the taller style window runs refer to Figure 36a and for the shorter style window runs with a shoulder and a cable retaining clip refer to Figure 36b.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 36a

FIGURE 36b

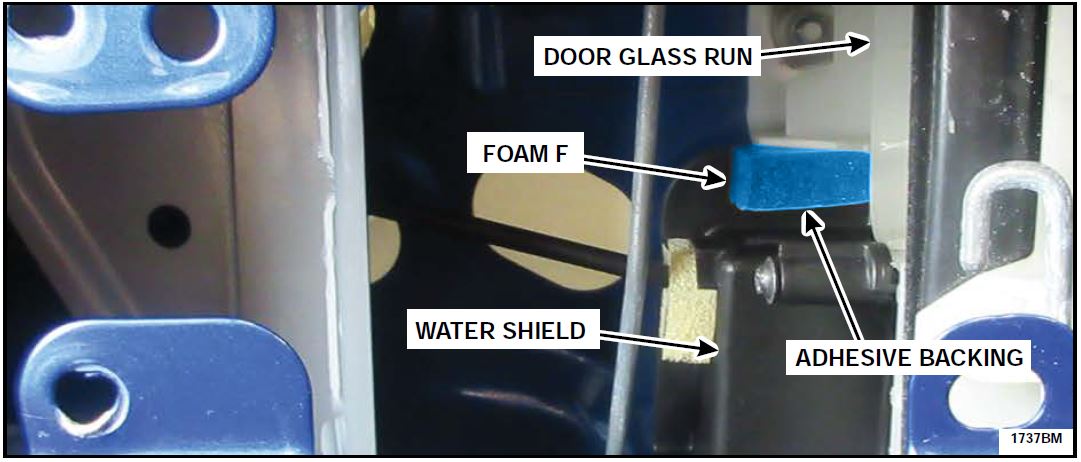

- Using a trim tool, install Foam F between the water shield and the door glass run. See Figure 37.

NOTE: Do not remove the adhesive backing from Foam F and install Foam F with the adhesive backing facing downward.

NOTE: Driver door shown, passenger door similar.

FIGURE 37

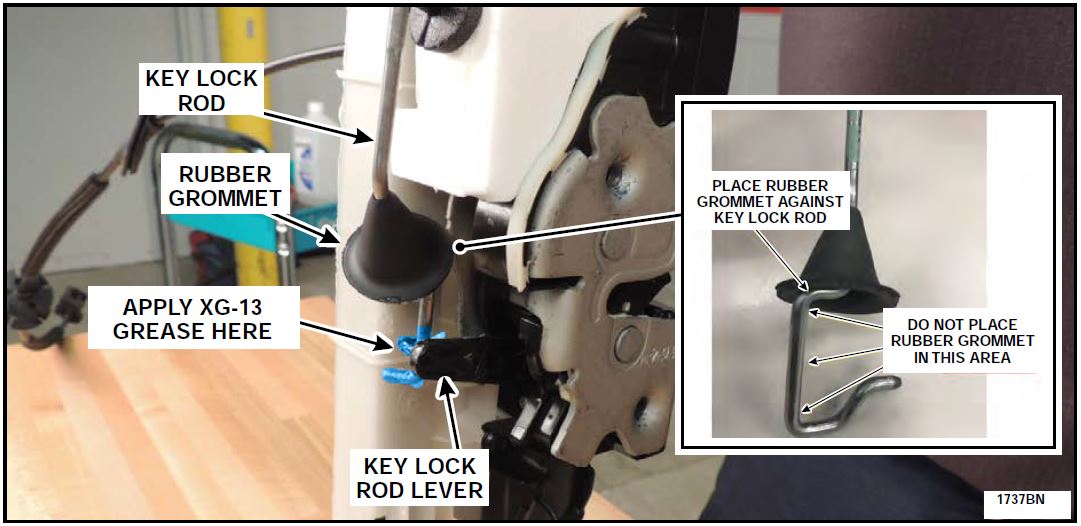

- For driver side only, apply Motorcraft® XG-13 grease to the area where the key lock rod attaches to the key lock rod lever. See Figure 38.

- For driver side only, install the rubber grommet onto the key lock rod over the key lock rod lever. The rubber grommet should be positioned as shown. The rubber grommet will sit sideways when installed properly. See Figure 38.

NOTE: Door latch assembly shown out of vehicle for clarity.

FIGURE 38

- Apply XG-11 grease on top of and around Foam D after Foam D is installed. The Foam D notch, the gap between the cable and Foam D, and the gap between the door glass run and Foam H must be covered with grease. See Figure 39.

NOTE: Do not allow the XG-11 grease to come into contact with moving components of the latch mechanism.

NOTE: Driver door shown, passenger door similar.

FIGURE 39

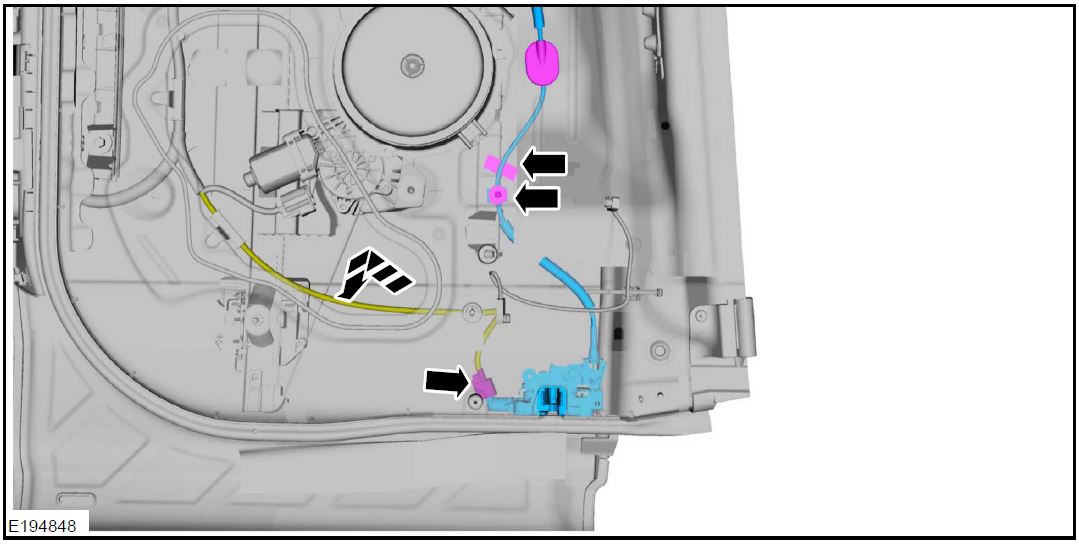

- If equipped, disconnect the interior door handle cable retaining clips from the door sheet metal.

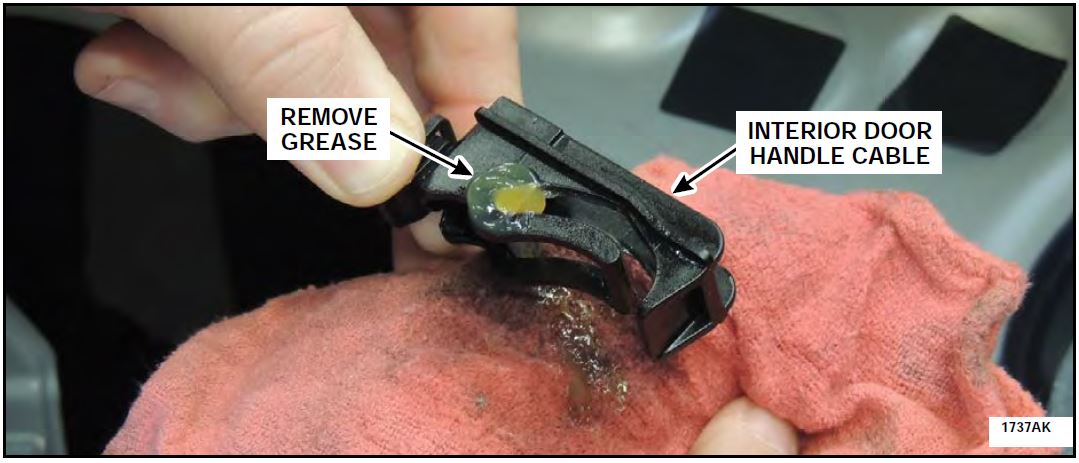

- Using isopropyl alcohol and a clean shop cloth, throughly remove grease from the interior door handle cable mechanism. See Figure 40.

FIGURE 40

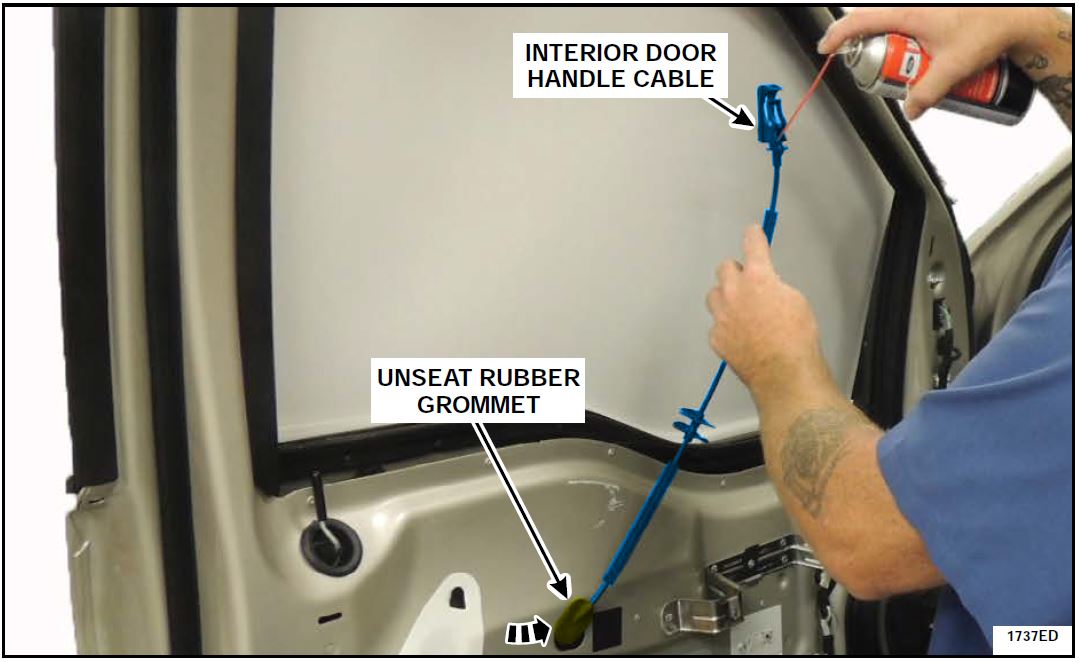

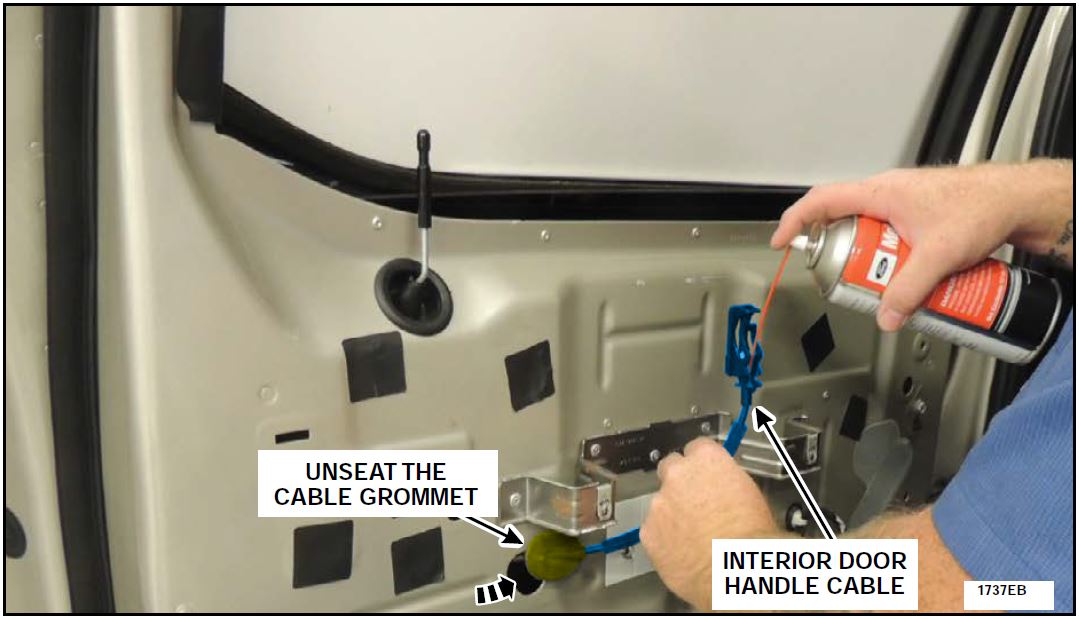

- Unseat the interior door handle cable rubber grommet and while holding the end of the cable in an upward position, spray Motorcraft® XL-6 Lubricant down into the cable for five seconds. See Figure 41.

NOTE: If the Motorcraft® XL-6 Lubricant container is not equipped with an applicator nozzle that can accommodate a straw, swap the applicator nozzle from another Motorcraft® chemical such as: XL-5 Multi-Purpose Grease Spray, XL-5-A Multi-Purpose Grease Spray or ZC-30-A Silicone Gasket Remover so a straw can be used. Spray a small amount to clear the applicator nozzle and straw prior to spraying the cable.

FIGURE 41

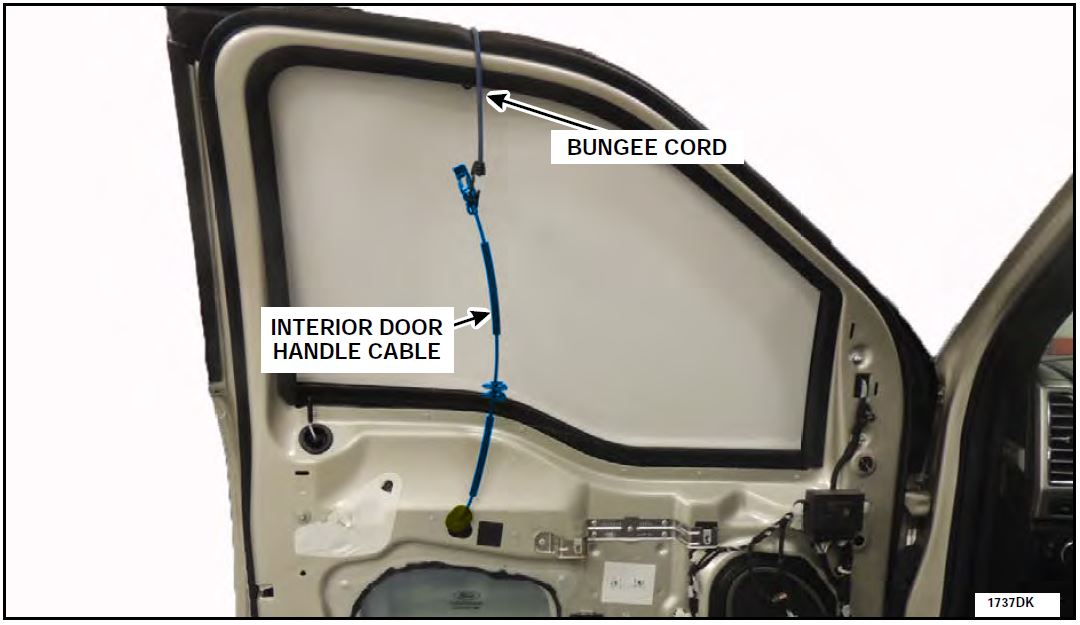

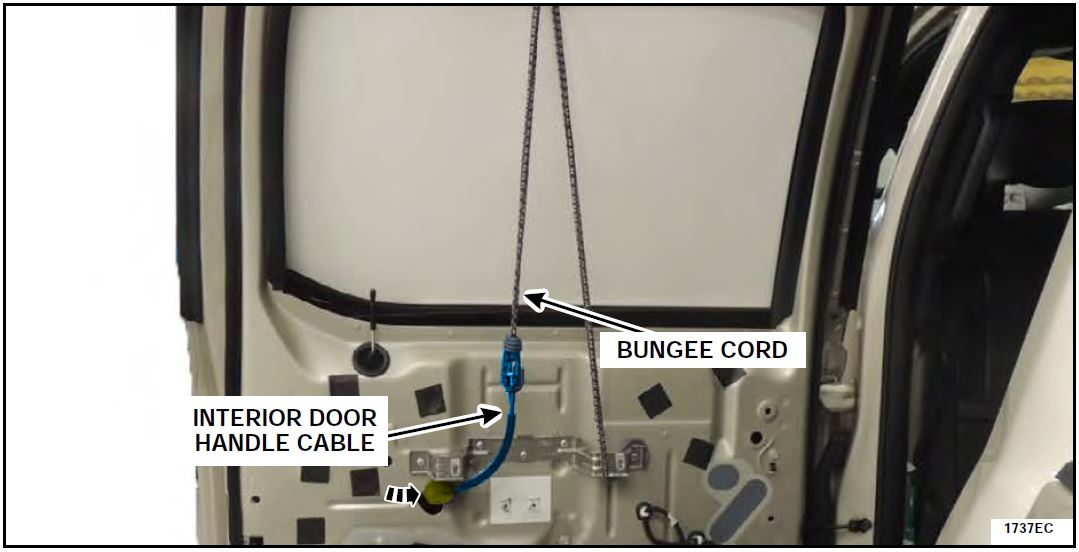

- Using a bungee cord or other similar device, secure the interior door handle cable to the door in an upward position to allow the Motorcraft® XL-6 Lubricant time to run down into the cable, until the interior door handle cable is reinstalled later in this procedure. See Figure 42.

FIGURE 42

NOTE: The use of disposable gloves is required.

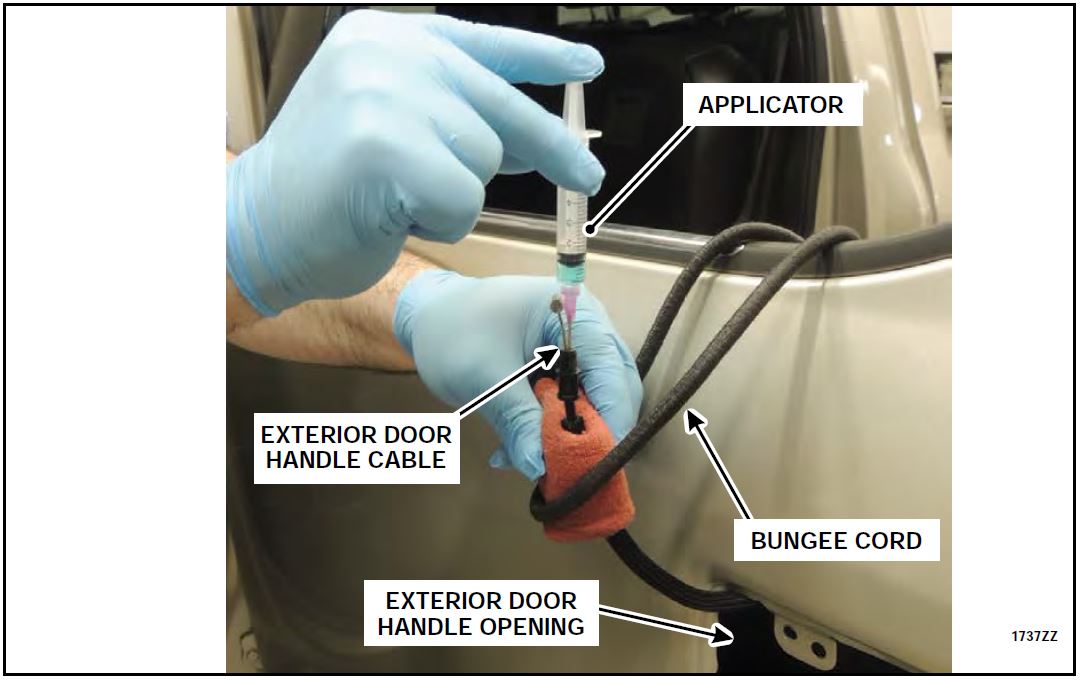

- Towel dry the exterior door handle cable to absorb any residual moisture. Using a bungee cord or other similar device secure the exterior door handle cable to the door in an upward position as shown in Figure 42, to allow the undiluted Motorcraft® Premium Windshield Wash Concentrate (ZC-32-B2) or a 99 percent methyl hydrate (methanol) product time to run down into the cable, until the exterior door handle cable is reinstalled later in this procedure.

- Using a locally obtained syringe, eye dropper or a similar applicator draw 10 ml of the undiluted Motorcraft® ZC-32-B2 Concentrate or a 99 percent methyl hydrate (methanol) product into the applicator. With the cable pulled out and the tip of the applicator positioned inside the arrowhead cable end fitting inject 2 ml between the cable shield and the cable then cycle the cable 5 times in and out of the cable shield. Repeat injecting fluid and cycling the cable a total of 5 times.

NOTICE: Place a shop towel around the exterior door handle cable, while performing this procedure, to prevent dripping onto the vehicle which could cause paint damage.

NOTE: Do not use a product that contains isopropyl alcohol. Only use a product containing methanol or a mix of methanol and ethylene glycol.

NOTE: Rear door shown, front door similar.

FIGURE 43

- Using a clean shop cloth and isopropyl alcohol, clean the highlighted mating surface area of the exterior front door handle. See Figure 44.

FIGURE 44

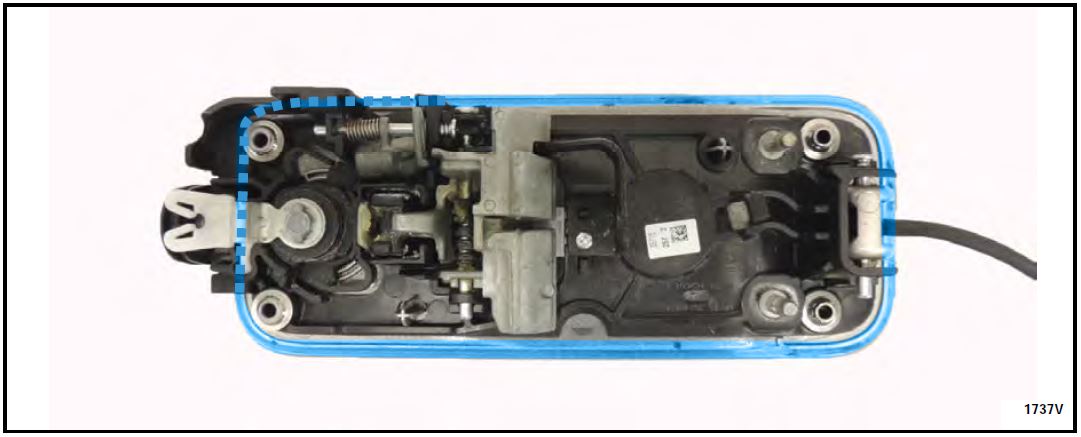

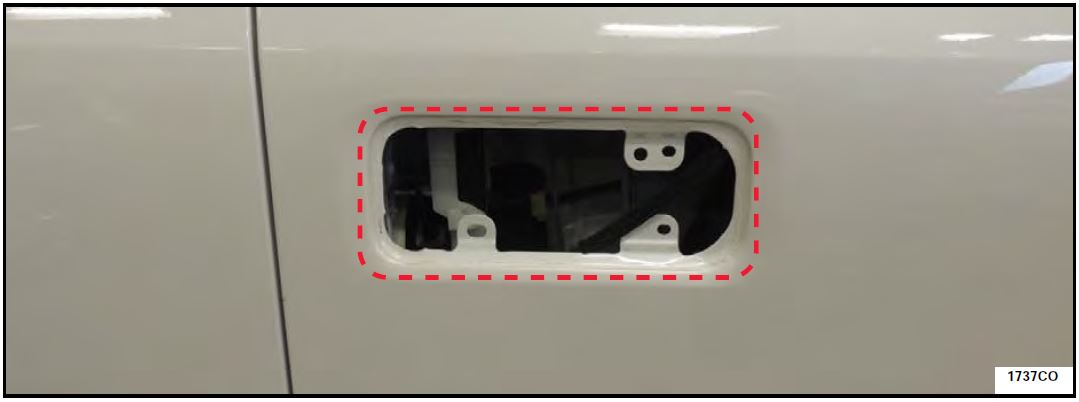

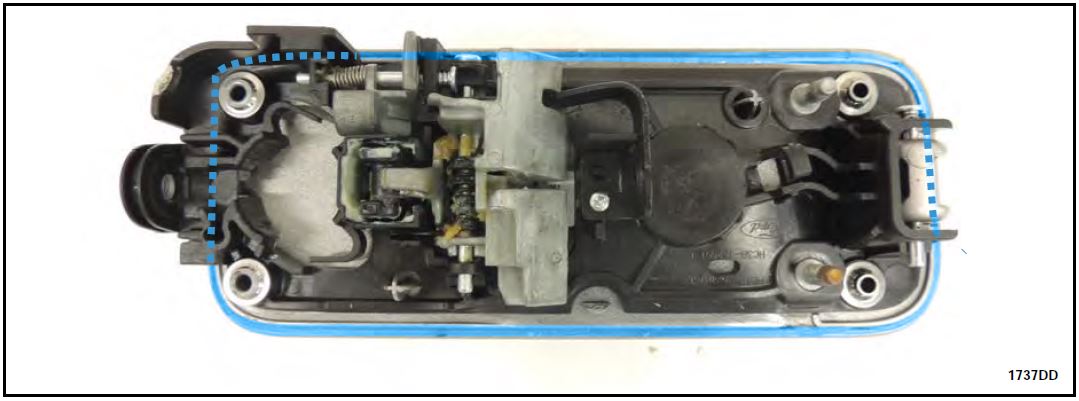

- Using a clean shop cloth and isopropyl alcohol clean inside the dotted lines on the mating surface area of the front exterior door handle openings. See Figure 45.

FIGURE 45

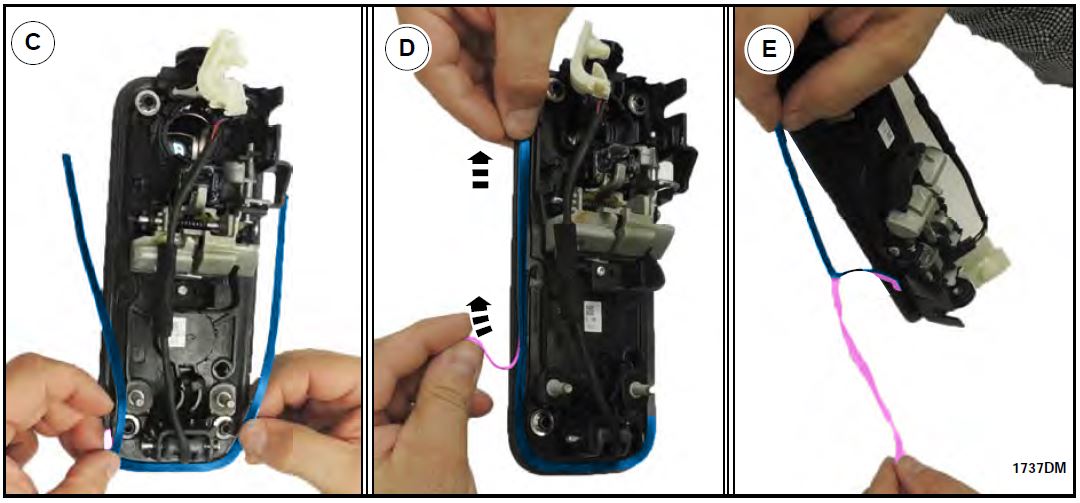

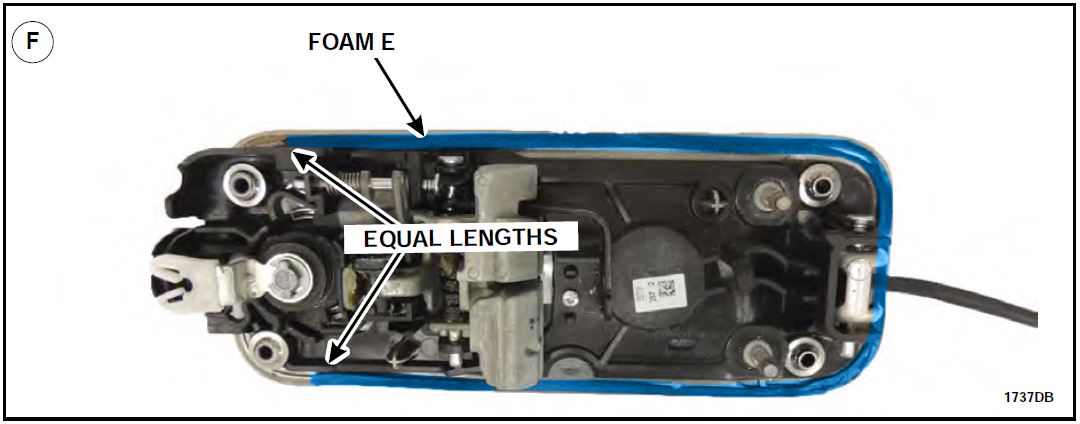

- Install Foam E around the perimeter of the exterior door handle on top of the existing seal.

NOTE: Foam E will not wrap around the entire perimeter of the exterior door handle.

NOTE: Proper placement of Foam E is crucial for proper sealing and to avoid appearance concerns.

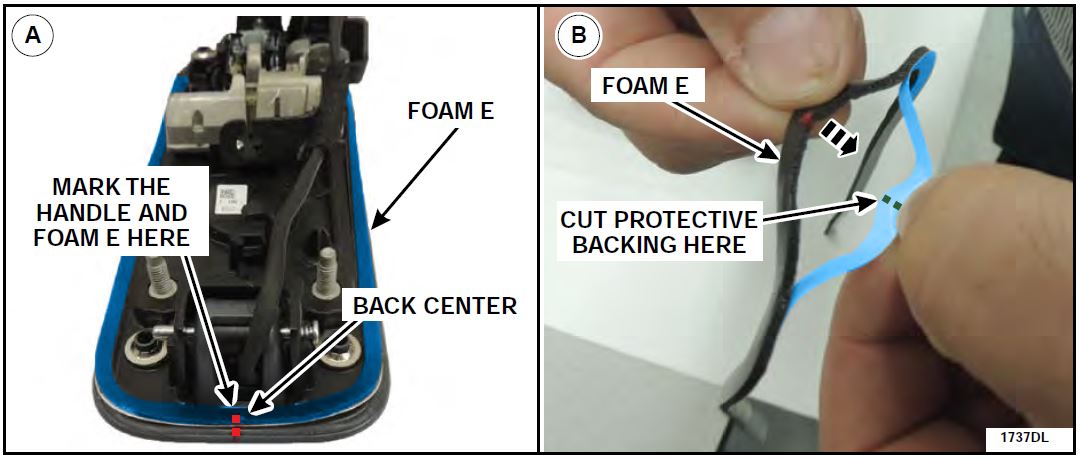

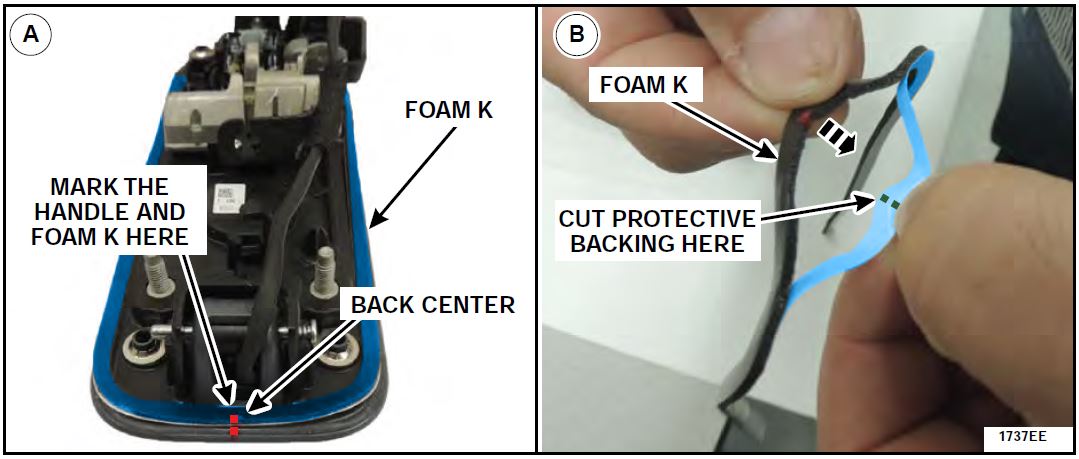

A. Lay out Foam E on the exterior door handle and mark center as shown in Figure 46.

B. Remove Foam E from the door handle and remove the back center portion of the adhesive backing then cut the protective backing in half. See Figure 46.

C. Align the marks made on the Foam E and exterior door handle and adhere the back center portion to the exterior door handle as shown in Figure 47.

D. Lay one side of Foam E down on the exterior door handle and without stretching the foam pull off the adhesive backing as you adhere Foam E to the exterior door handle as shown in Figure 47.

E. Remove the protective backing from the other side of Foam E as shown in Figure 47.

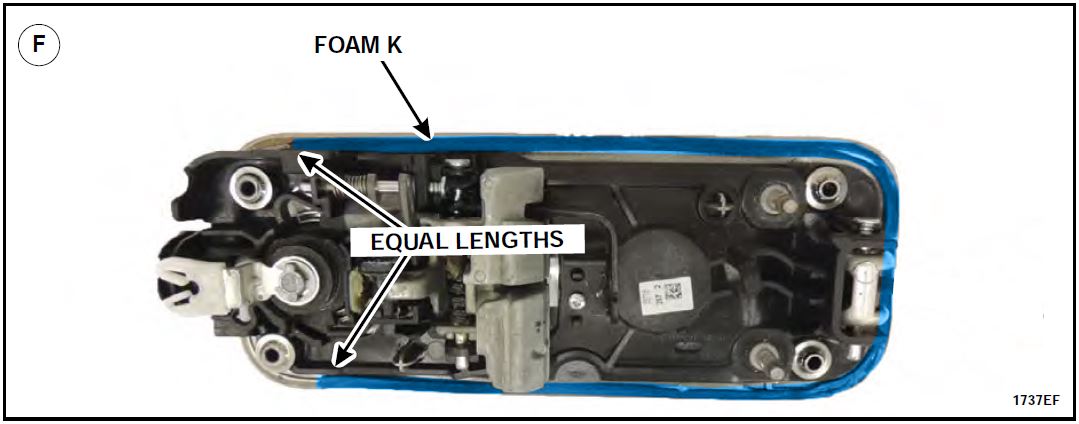

F. Without stretching the foam adhere it to the exterior door handle ensuring that both sides of Foam E are of equal length once secured. See Figure 48.

FIGURE 46

FIGURE 47

FIGURE 48

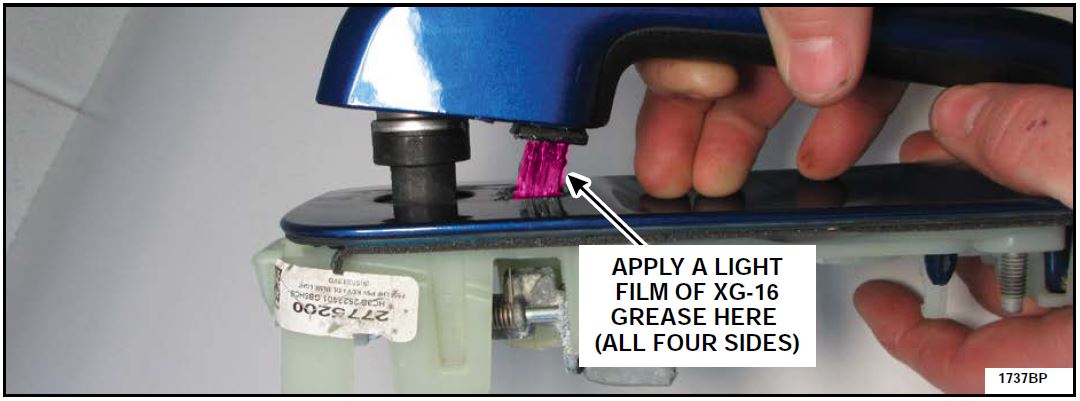

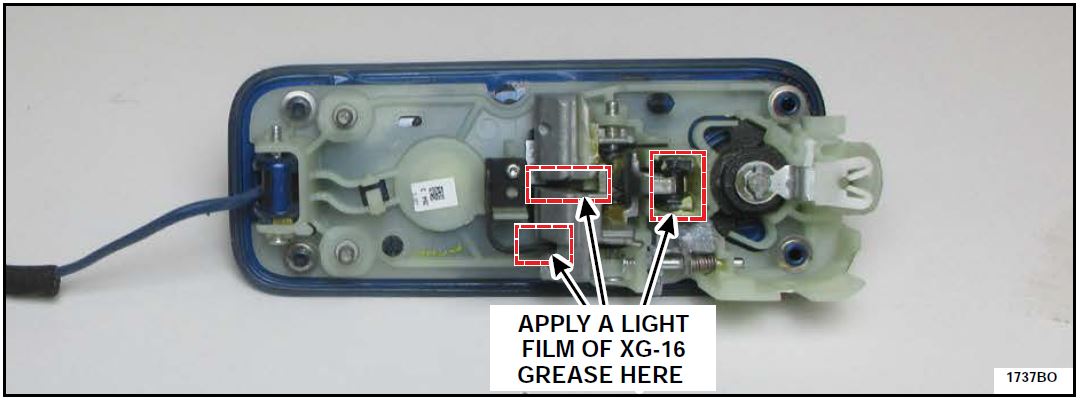

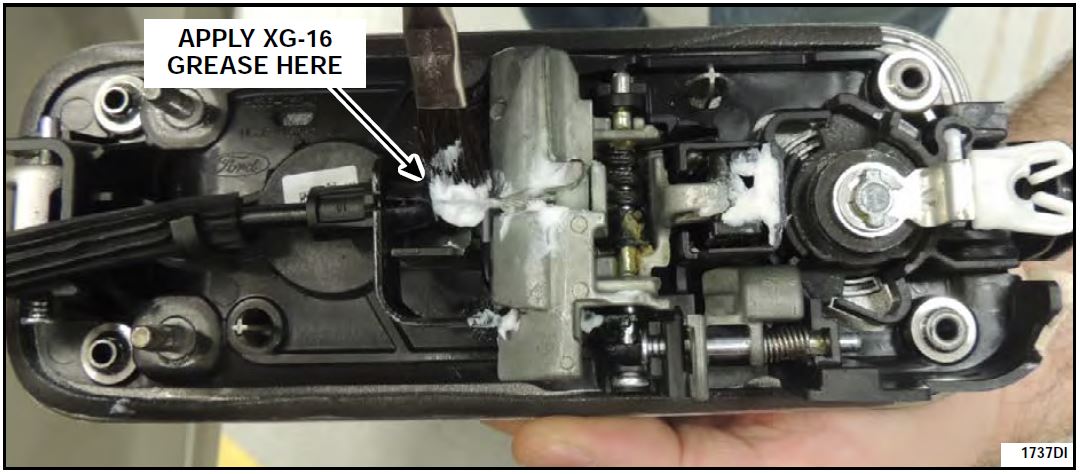

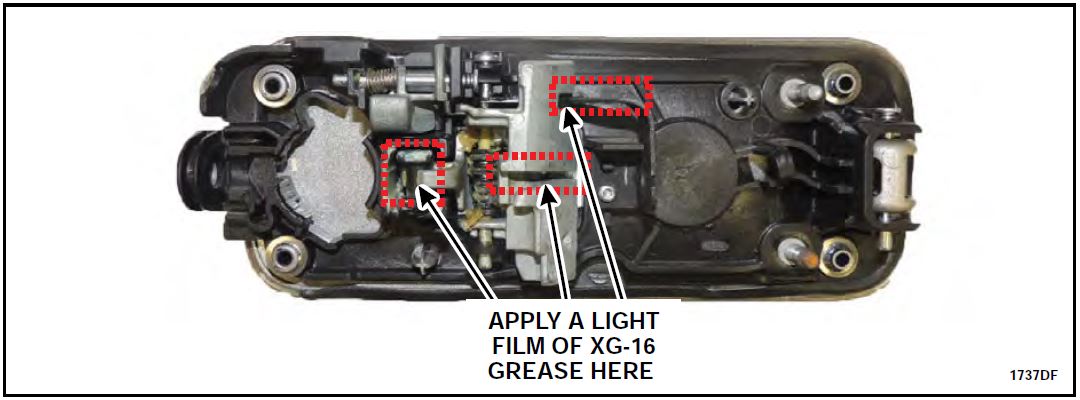

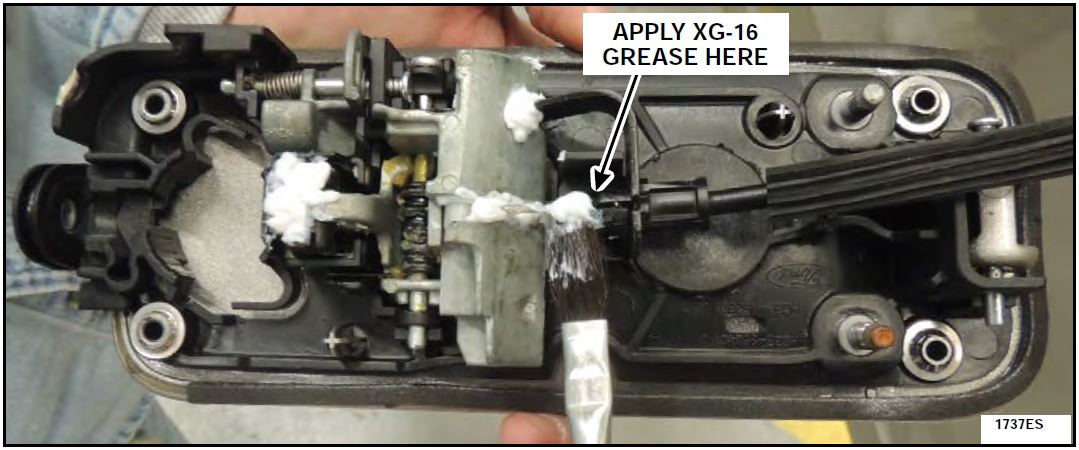

- Using a clean shop cloth and isopropyl alcohol, clean the handle plunger then using a brush apply a light film of Motorcraft® XG-16 low temperature grease to all four sides of the exterior door handle plunger and to the mechanisms in the areas shown in Figures 49 and 50.

FIGURE 49

FIGURE 50

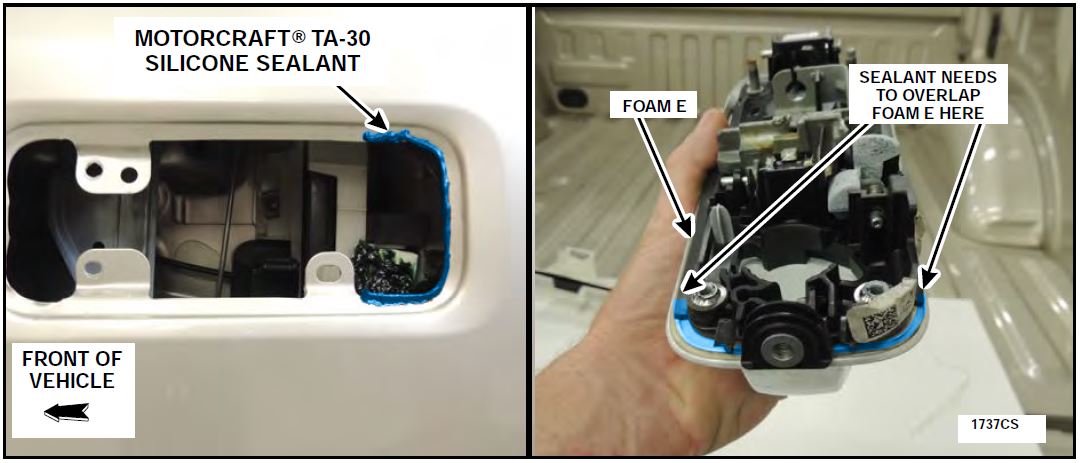

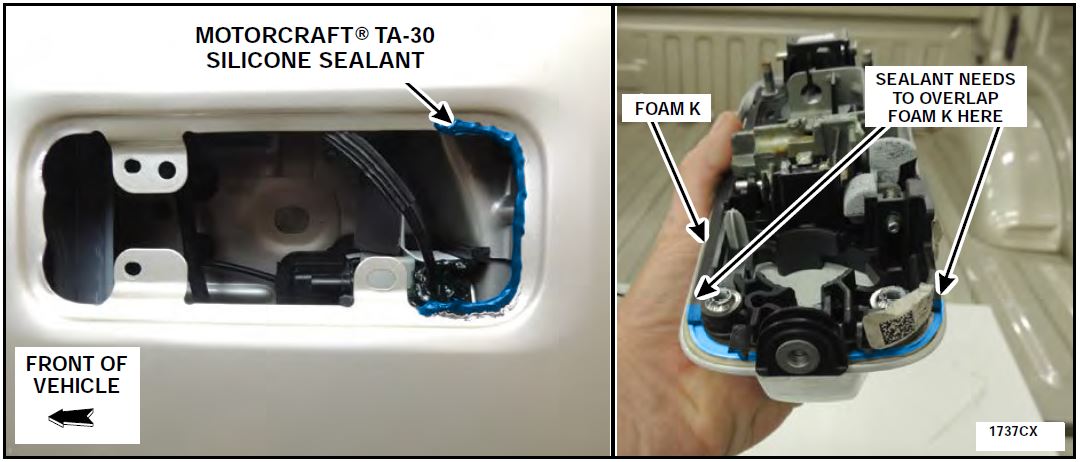

- Apply a bead of Motorcraft® TA-30 silicone sealant to the latch side area of the front door exterior handle opening making sure that the sealant will overlap with the Foam E on the exterior door handle. See Figure 51.

NOTE: Proper placement of the Motorcraft® TA-30 silicone sealant is crucial for proper sealing and to avoid appearance concerns.

NOTE: Driver door shown, passenger door similar.

FIGURE 51

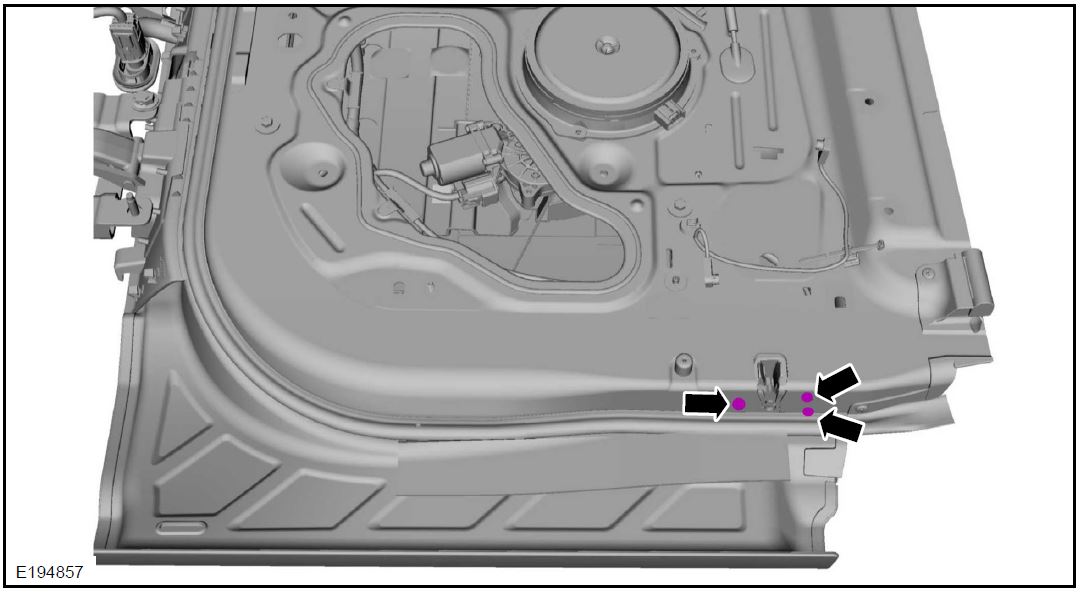

- Remove the bungee cords used to hold the interior and exterior door handle cables up, seat the rubber grommet and if equipped, reinstall the interior door handle cable retaining clips.

- Reconnect the exterior door handle cable to the door handle, then lubricate the door handle cable end with Motorcraft® XG-16 low temperature grease, as shown in Figure 52.

FIGURE 52

- Install a new handle cable wiper clip on the exterior door handle cable end. See Figure 53.

FIGURE 53

- Reinstall the front exterior door handles. Please follow the WSM procedures in Section 501-14.

NOTICE: Reinstall the exterior door handle cable and retaining clips in the original factory position.

- Clean any excessive silicone around the exterior door handle perimeter with isopropyl alcohol, Q-tips® and a clean shop cloth to avoid appearance concerns.

- Determine next steps based on vehicle and cab configuration.

- For all Regular Cab vehicles, F-150 Super Cab vehicles without safety recall 17S33 open, and all F-250-F-550 Super Cab vehicles, the repair is complete.

- For all Crew Cab vehicles, proceed to the Rear Door Service Procedure (Page 38).

- For F-150 Super Cab vehicles with safety recall 17S33 open, proceed to the Rear Door Lower Latch Water Shield Kit Installation Procedure (Page 69).

Rear Door Service Procedure (Crew Cab Vehicles)

- Is safety recall 17S33 open?

- Yes – Proceed to the Rear Door Latch Water Shield Kit Installation Procedure (Crew Cab Vehicles).

- No – Proceed to the Rear Door Glass Run and Belt Moulding Sealing Procedure (Crew Cab Vehicles). (Page 42)

Rear Door Latch Water Shield Kit Installation Procedure (Crew Cab Vehicles With Safety Recall 17S33 Open)

NOTE: This procedure uses a different door latch water shield attachment procedure than what was previously used in TSB 16-0155. Do not attempt to use TSB parts to perform this procedure.

NOTE: Procedure to be performed on both rear doors.

NOTE: The window must be in the closed (up) position when performing this procedure.

NOTICE: Do not allow the door trim panel or exterior door handle to hang by the door handle cables or damage to the cable and door may occur.

- Remove the exterior rear door handles. Please follow the WSM procedures in Section 501-14.

NOTE: The interior grab handle cover clips can be reused for this repair. Only replace if damaged.

- Remove the lock rod assembly from the rear door latch. See Figure 54.

- Use the male end of a 1/4″ extension to spread apart the lock rod retainer and remove the rod from the door latch.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 54

- Remove and discard the rubber drain plug and clean any obstructions, debris, foreign material and residual water from all of the door drain holes using compressed air and a tool such as a plastic trim tool or a zip tie. See Figure 55.

NOTE: Front passenger door shown, all doors similar.

FIGURE 55

- Using compressed air, blow out any debris or residual water from the door latch assembly, exterior door handle mechanism and cables for thirty seconds. Blow drying with compressed air for thirty seconds is critical to remove as much moisture as possible. See Figure 56.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 56

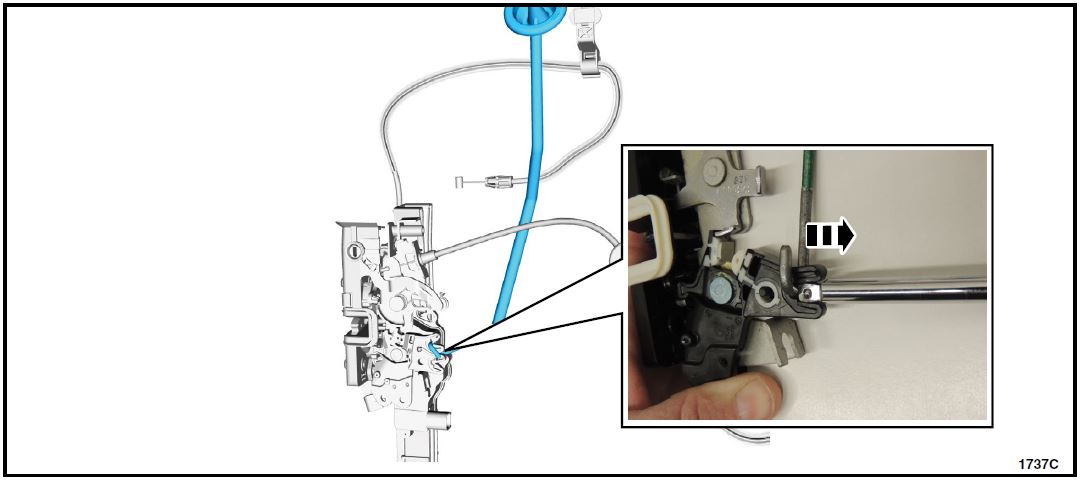

- Install the door latch water shield into position. See Figure 57.

NOTE: The water shield is properly installed when the latch cable is fitted in the notch of the water shield and the fastener holes align.

- Install the new screws into the top and bottom holes of the shield. See Figure 57.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 57

- Refer to Figure 58 to determine if the door latch is equipped with the new style lock rod.

Is the door latch equipped with the new style lock rod or manual locks?

Yes – Reinstall the lock rod if equipped and proceed to the Rear Door Glass Run and Belt Moulding Sealing Procedure (Page 42).

No – Proceed to Step 8.

FIGURE 58

- Lock rod replacement procedure. See Figure 59.

NOTE: If a replacement lock rod already has a button and grommet installed, transfer of the components is not required.

a. Transfer the grommet, sleeve and button from the original lock rod to the new lock rod.

b. Apply a bead of Motorcraft® Instant Gel Adhesive TA-19-C or equivalent to the lock rod prior to threading the button onto the new lock rod.

c. When threading the button onto the new lock rod, stop threading when some resistance is met.

d. Ensure both rear lock rod buttons are installed at similar heights.

e. Reinstall the lock rod.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 59

- Proceed to the Rear Door Glass Run and Belt Moulding Sealing Procedure (Page 42).

Rear Door Glass Run and Belt Moulding Sealing Procedure (Crew Cab Vehicles)

Complete Rear Door Part Kit

FIGURE 60

NOTE: The parts being installed in this procedure are not labeled. Refer to Figure 60 for component identification.

Rear Door Glass Run and Belt Moulding Sealing Components

NOTE: Procedure to be performed on both rear doors.

FIGURE 61

NOTE: Procedure to be performed on both rear doors.

NOTE: The window must be in the closed (up) position when performing this procedure.

NOTICE: Do not allow the door trim panel or exterior door handle to hang by the door handle cables or damage to the cable and door may occur.

- Remove the exterior rear door handles. Please follow the Workshop Manual (WSM) procedures in Section 501-14.

NOTE: The interior grab handle cover clips can be reused for this repair. Only replace if damaged.

- If a cable wiper clip is present on the exterior door handle cable end, remove and discard the cable wiper clip. See Figure 62.

NOTE: Front exterior door handle shown, all exterior door handles similar.

FIGURE 62

- Inspect the interior door handle to latch release cable for kinking. See Figure 63.

– Were any kinks visible on the interior door handle release cable?

Yes – Proceed to Step 4.

No – Proceed to Step 6.

FIGURE 63

NOTE: It is not necessary to detach the exterior door handle cable from the retaining bracket or remove the exterior door handle cable from the latch.

- Remove the rear door latch and install a new interior door handle release cable. Please follow the WSM procedures in Section 501-14.

CAUTION: Use caution not to kink the cables during reassembly of the door latch. NOTE: Do not reinstall the door panel, watershield or the exterior door handle at this time.

- Reassemble and reinstall the rear door latch. Complete by reversing the WSM procedures in Section 501-14. Then proceed to Step 6.

- If water shield kit installation was not necessary, remove and discard the rubber drain plug and clean any obstructions, debris, foreign material and residual water from all of the door drain holes using compressed air and a tool such as a plastic trim tool or a zip tie. See Figure 64.

NOTE: Front passenger door shown, all doors similar.

FIGURE 64

- If not previously performed, use compressed air and blow out any debris or residual water from the

door latch assembly, exterior door handle mechanism and cables for thirty seconds. Blow drying with

compressed air for thirty seconds is critical to remove as much moisture as possible. See Figure 65.

NOTE: Driver front door latch shown, all door latches similar.

FIGURE 65

- Position the rear door window glass down.

- Remove the rear door inner belt moulding and position aside the latch side of the door glass top run. See Figure 66.

FIGURE 66

- If present, remove and discard the foam on the door outer belt moulding at the location shown in Figure 67.

FIGURE 67

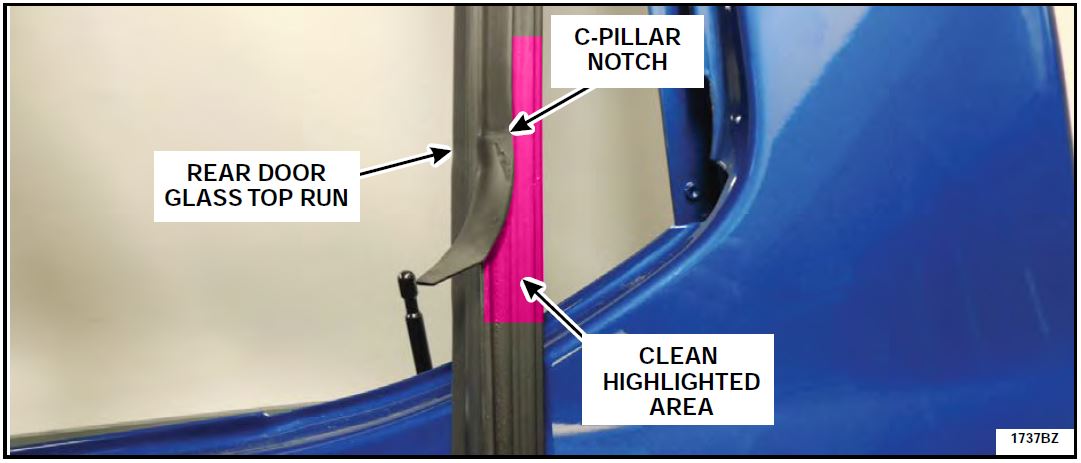

- Clean the highlighted area of the outer belt moulding with isopropyl alcohol and a clean shop cloth. See Figure 68.

NOTE: Make sure to clean past the second clip.

FIGURE 68

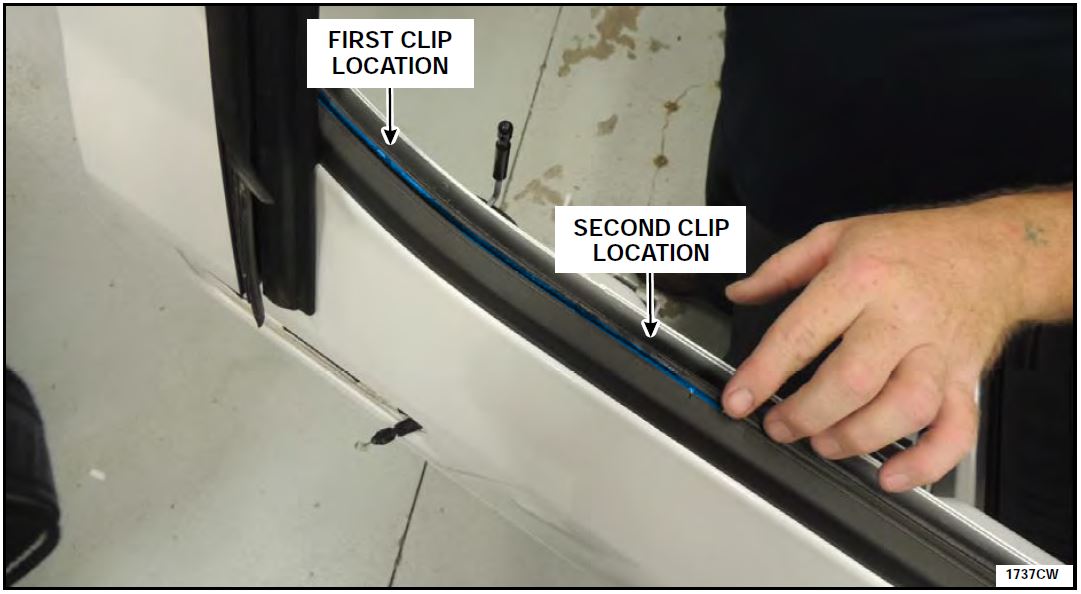

- Apply Motorcraft® TA-30 silicone sealer to the area highlighted on the outer belt moulding. Using your finger, smooth out the sealer to establish an even surface. See Figures 69 and 70.

NOTE: Completely covering the belt moulding metal clips is crucial for proper sealing. See Figure 70.

FIGURE 69

FIGURE 70

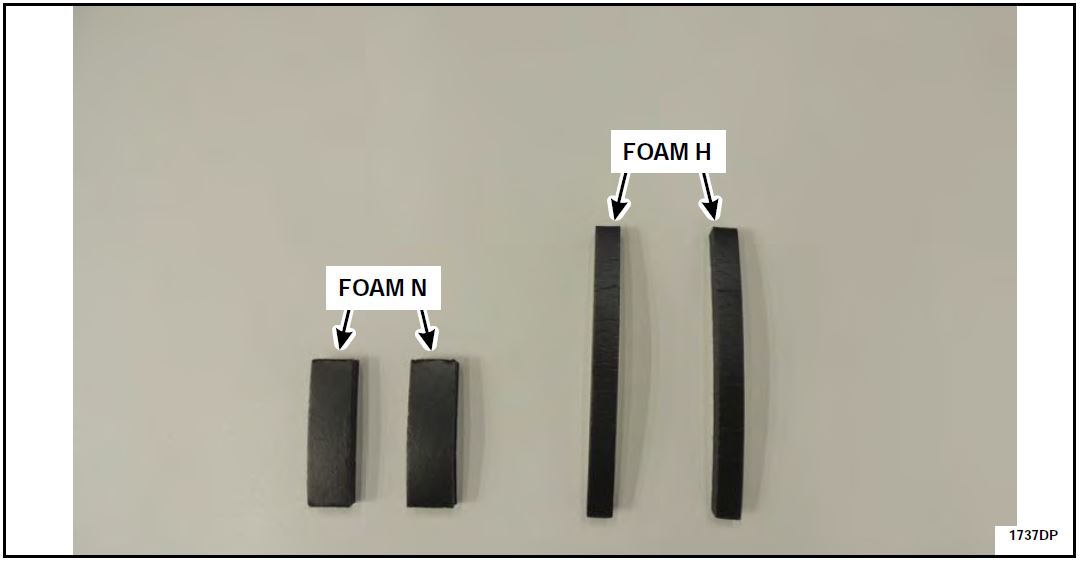

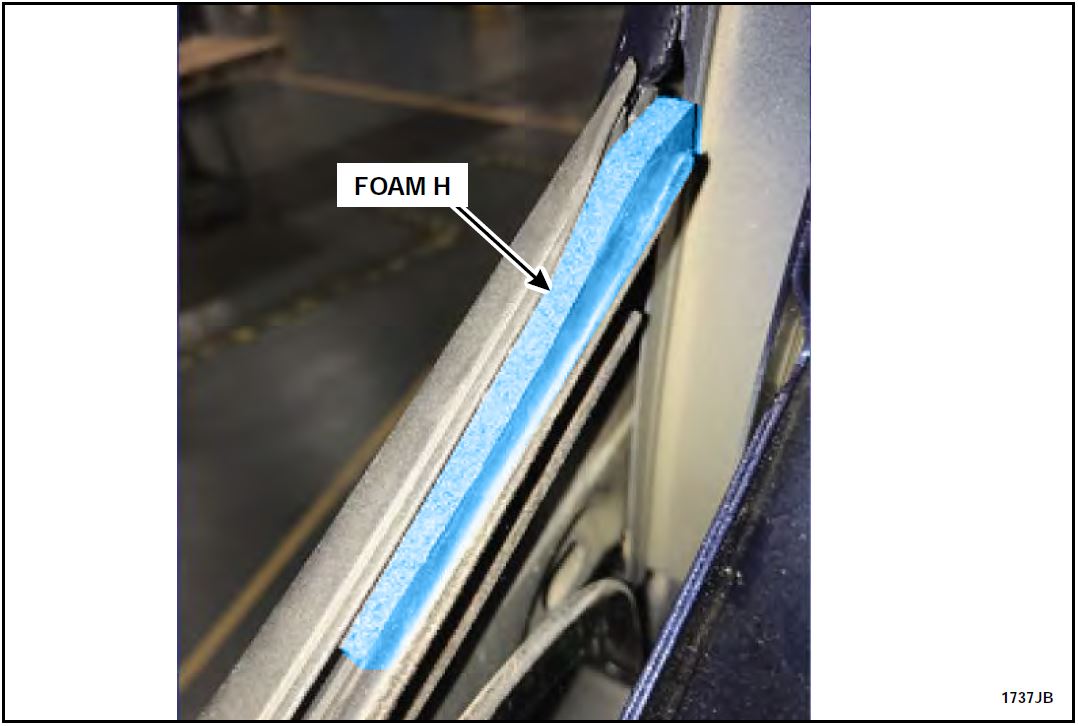

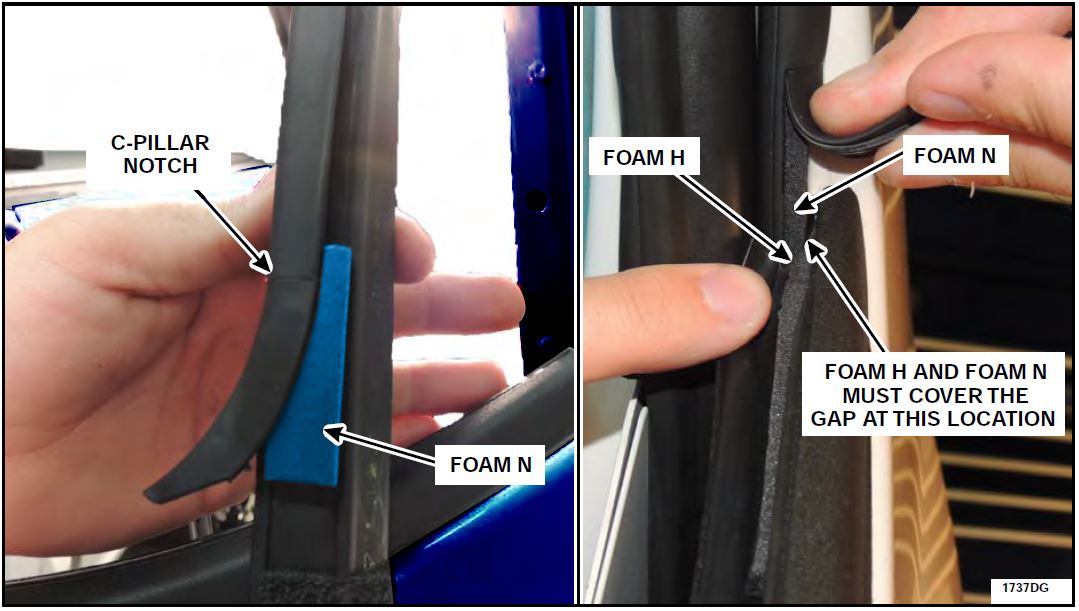

- Install Foam H to the C-pillar end of the outer belt moulding. See Figure 71.

FIGURE 71

- Remove any excessive silicone in visible areas on the outer belt moulding with isopropyl alcohol and a clean shop cloth.

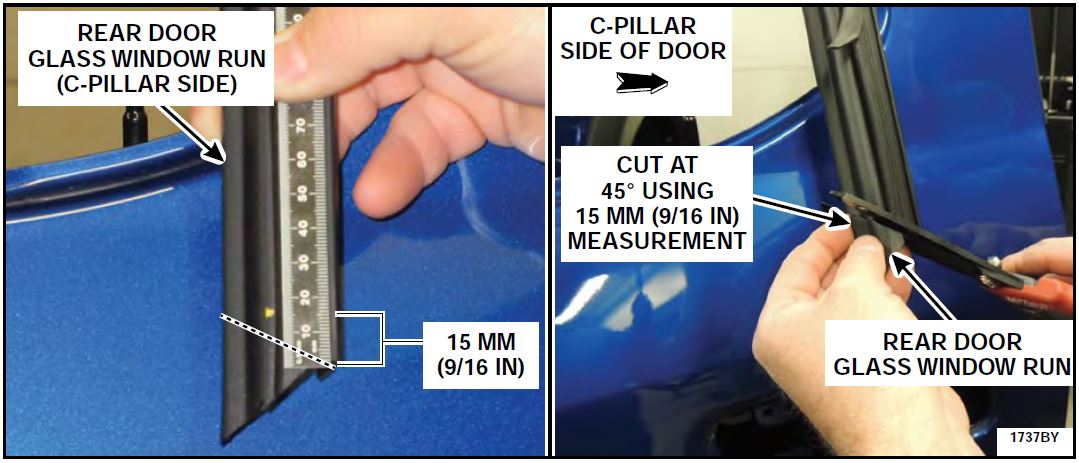

- Modify the rear door glass top run. See Figure 72.

a. Measure 15 mm (9/16 in) from the inboard bottom corner of the door glass top run.

b. Starting at the bottom outboard corner of the rear door glass top run, cut a 45° notch using the previous measurement as a guide.

FIGURE 72

- If present, remove and discard the felt on the rear door glass top run. See Figure 73.

FIGURE 73

- Clean the highlighted area of the rear door glass top run with isopropyl alcohol and a clean shop cloth. See Figure 74.

FIGURE 74

- Install Foam N to the highlighted area of rear door glass top run making sure that the Foam N is under the C-Pillar notch. See Figure 74.

FIGURE 74

- With the rear door latch side door glass top run still positioned aside raise the rear door window glass three quarters of the way up. See Figure 76.

NOTICE: Use care when raising window glass to not pinch door glass top run or scratch the glass.

FIGURE 76

- Modify the rear door lock rod grommet. See Figure 77.

a. Remove the rear door lock rod grommet from the lock rod.

b. Cut approximately 6 mm (0.25 in)off the top of the grommet.

c. Install the rear door lock rod grommet back onto the lock rod.

d. Using a utility knife, cut four 6 mm (0.25 in) long slits approximately 90° apart into the lower portion of the rear door lock rod grommet.

FIGURE 77

- Proceed to the Rear Door Latch and Handle Service Procedure.

Rear Door Latch and Handle Service Procedure (Crew Cab Vehicles)

Rear Door Latch and Handle Sealing Components

NOTE: Procedure to be performed on both rear doors.

FIGURE 78

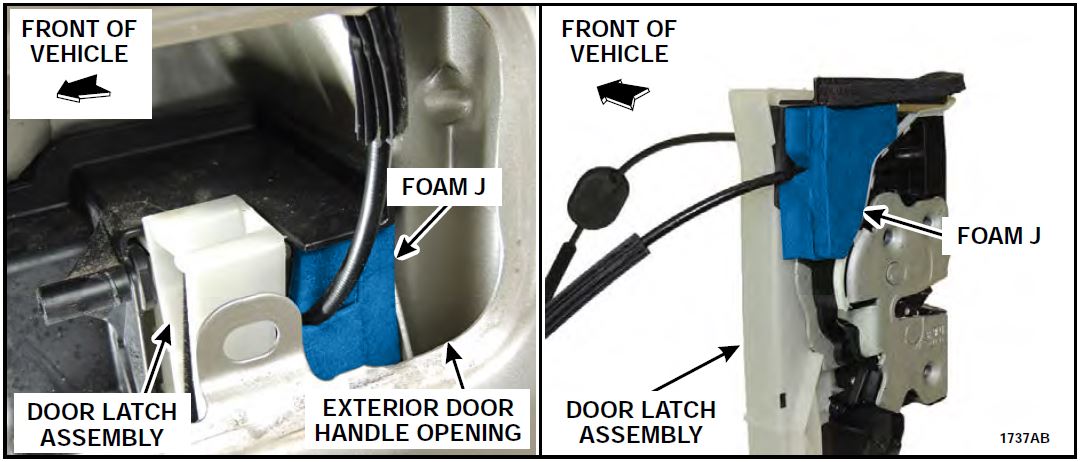

- Install Foam J onto the rear door latch. See Figure 79.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 79

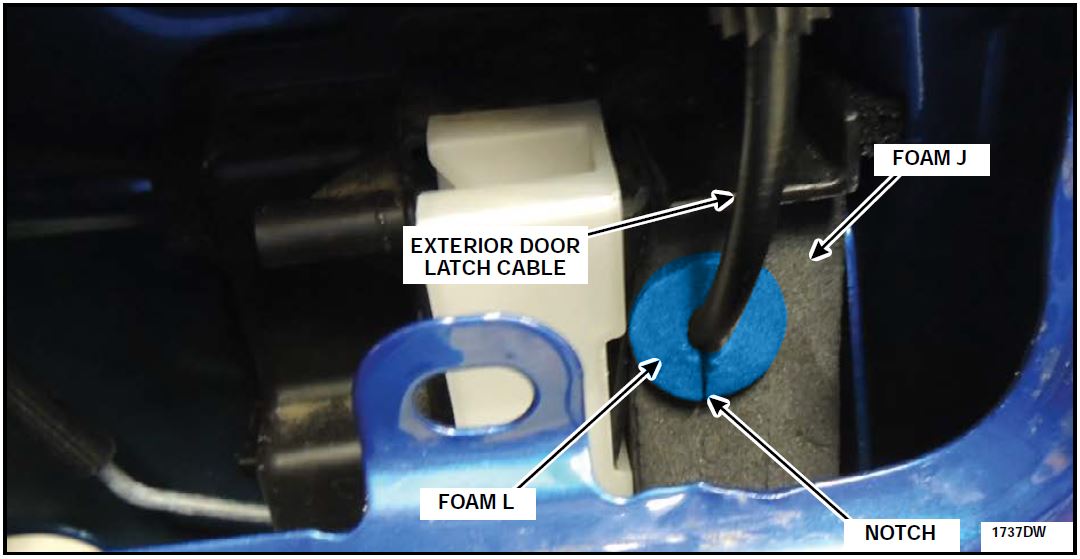

- Install Foam L over the door latch cable and onto Foam J to cover the gap between the exterior door latch cable and Foam J. See Figure 80.

- The notch of foam L must point downward when installed.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 80

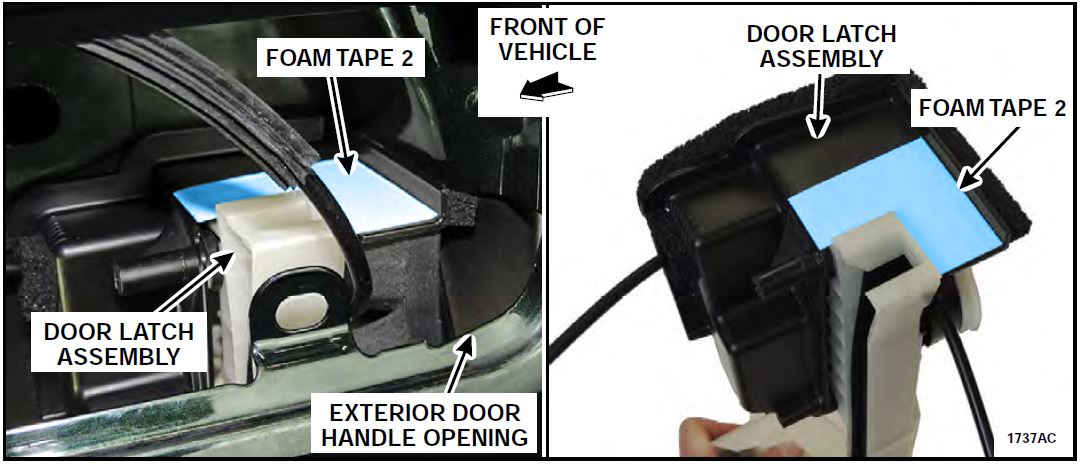

- Clean the highlighted area on top of the door latch water shield with isopropyl alcohol and a clean shop cloth where the Foam Tape 2 will be installed. See Figure 81.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 81

- Install Foam Tape 2 on top of the rear door latch water shield. See Figures 82.

- Make sure that Foam Tape 2 attaches to the water shield and to the door glass run.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 82

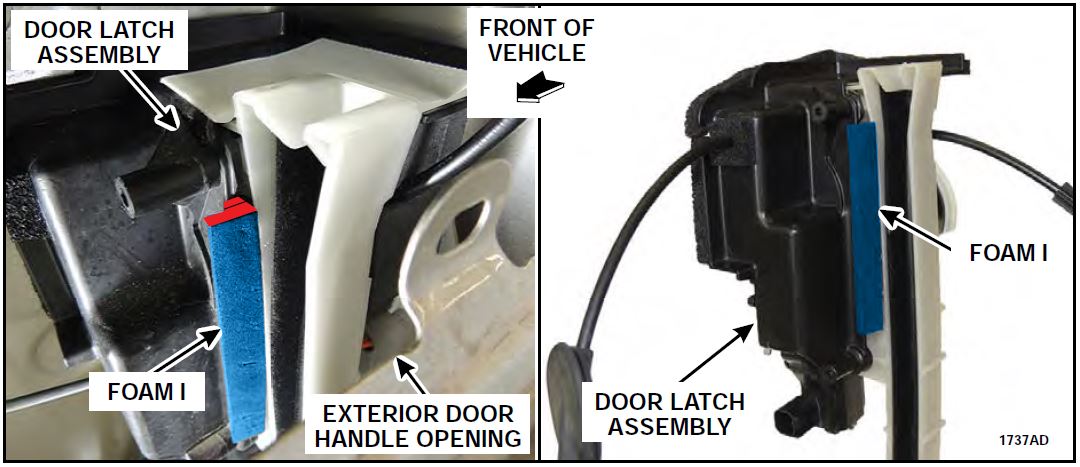

- Install Foam I to cover the gap between the rear door latch assembly water shield and the door glass run. See Figure 83.

NOTE: Driver door latch shown, passenger door latch similar.

FIGURE 83

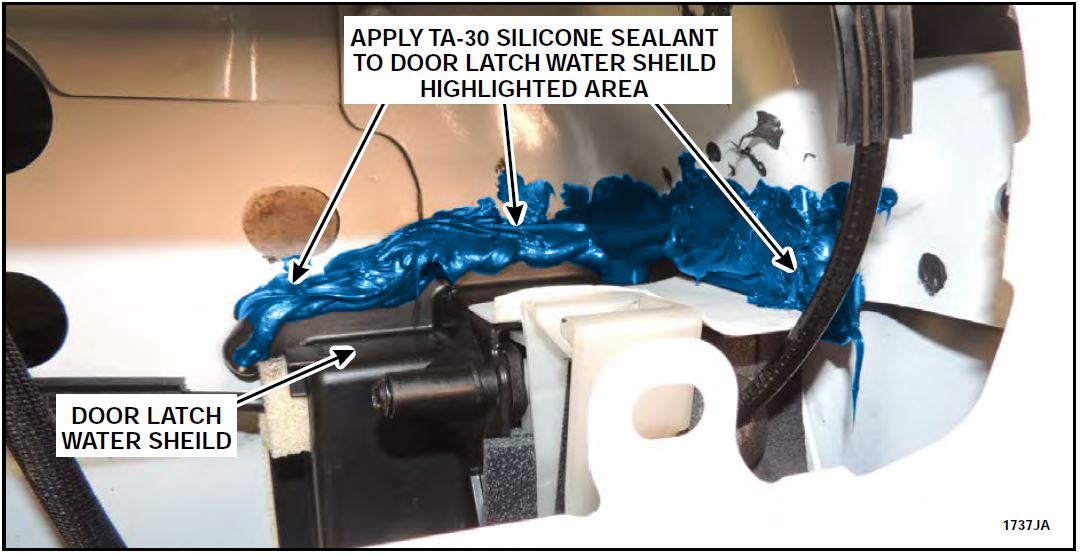

- Apply Motorcraft® TA-30 silicone sealant in and over the mating area of the water shields to the door. Using light finger pressure smooth the bead of silicone. See Figure 84.

FIGURE 84

- Position the rear door window glass down.

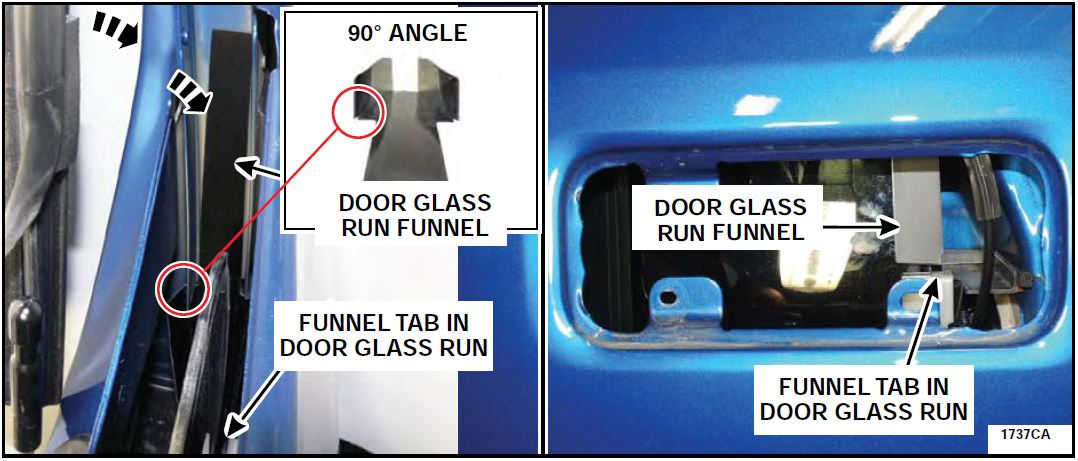

- Install the door glass run funnel (132mm funnel wings), ensuring the lower tab is situated in the door glass run and the funnel sides sit at a 90° angle above the door glass run. Refer to Attachment V for additional information. See Figure 85.

NOTE: Verify the sides of the funnel are bent to 90° prior to installation.

FIGURE 85

- Install the rear door glass top run and inner belt moulding. See Figure 66.

NOTICE: When installing the rear door glass top run make sure not to bend or damage the door glass run funnel. Check through the exterior door handle opening to verify that the funnel is positioned correctly.

- Position the rear door window glass up.

- Apply supplied Foam Tape 1 in the location shown to hold the funnel in place. See Figure 86.

FIGURE 86

- Apply XG-11 grease on top of and around Foam L. The Foam L notch, the gap around the cable and Foam L, and the gap between the door latch assembly and Foam J must be filled with grease. See Figure 87.

NOTE: Do not allow the XG-11 grease to come into contact with moving components of the latch mechanism.

FIGURE 87

- Using isopropyl alcohol and a clean shop cloth, throughly remove grease from the interior door handle cable mechanism. See Figure 88.

FIGURE 88

- Unseat the interior door handle cable rubber grommet and while holding the end of the interior door handle cable in an upward position, spray Motorcraft® XL-6 Lubricant for five seconds down into the cable. See Figure 89.

NOTE: If the Motorcraft® XL-6 Lubricant container is not equipped with an applicator nozzle that can accommodate a straw, swap the applicator nozzle from another Motorcraft® chemical such as: XL-5 Multi-Purpose Grease Spray, XL-5-A Multi-Purpose Grease Spray or ZC-30-A Silicone Gasket Remover so a straw can be used. Spray a small amount to clear the applicator nozzle and straw prior to spraying the cable.

FIGURE 89

- Using a bungee cord or other similar device, secure the interior door handle cable to the door in an upward position to allow the lubricant time to run down into the cable, until the interior door handle cable is reinstalled later in this procedure. See Figure 90.

FIGURE 90

NOTE: The use of disposable gloves is required.

- Towel dry the exterior door handle cable to absorb any residual moisture. Using a bungee cord or other similar device secure the exterior door handle cable to the door in an upward position as shown in Figure 91, to allow the undiluted Motorcraft® Premium Windshield Wash Concentrate (ZC-32-B2) or a 99 percent methyl hydrate (methanol) product time to run down into the cable, until the exterior door handle cable is reinstalled later in this procedure.

- Using a locally obtained syringe, eye dropper or a similar applicator draw 10 ml of the undiluted Motorcraft® ZC-32-B2 Concentrate or a 99 percent methyl hydrate (methanol) product into the applicator. With the cable pulled out and the tip of the applicator positioned inside the arrowhead cable end fitting inject 2 ml between the cable shield and the cable then cycle the cable 5 times in and out of the cable shield. Repeat injecting fluid and cycling the cable a total of 5 times.

NOTICE: Place a shop towel around the exterior door handle cable, while performing this procedure, to prevent dripping onto the vehicle which could cause paint damage.

NOTE: Do not use a product that contains isopropyl alcohol. Only use a product containing methanol or a mix of methanol and ethylene glycol.

FIGURE 91

- Using a clean shop cloth and isopropyl alcohol, clean the highlighted mating surface area of the exterior door handle. See Figure 92.

FIGURE 92

- Using a clean shop cloth and isopropyl alcohol, clean inside the dotted lines on the mating surface area of the exterior door handle opening. See Figure 93.

FIGURE 93

- Install Foam K around the perimeter of the exterior door handle on top of the existing seal.

NOTE: Foam K will not wrap around the entire perimeter of the exterior door handle.

NOTE: Proper placement of Foam K is crucial for proper sealing and to avoid appearance concerns.

A. Lay out Foam K on the exterior door handle and mark center as shown in Figure 94.

B. Remove Foam K from the door handle and remove the back center portion of the adhesive backing then cut the protective backing in half. See Figure 94.

C. Align the marks made on the Foam K and exterior door handle and adhere the back center portion to the exterior door handle as shown in Figure 95.

D. Lay one side of Foam K down on the exterior door handle and without stretching the foam pull off the adhesive backing as you adhere Foam K to the exterior door handle as shown in Figure 95.

E. Remove the protective backing from the other side leg of Foam K as shown in Figure 95.

F. Without stretching the foam adhere it to the exterior door handle ensuring that both sides of Foam K are of equal length once secured. See Figure 96.

FIGURE 94

FIGURE 95

FIGURE 96

- Using a clean shop cloth and isopropyl alcohol, clean the handle plunger then, using a brush, apply a light film of Motorcraft® XG-16 low temperature grease to all four sides of the exterior door handle plunger and to the mechanisms in the areas shown in Figures 97 and 98.

FIGURE 97

FIGURE 98

- Apply a bead of Motorcraft® TA-30 silicone sealant to the rear vertical area of the rear door metal surface making sure that the sealant will overlap with the Foam K on the exterior door handle.

See Figure 99.

NOTE: Proper placement of the Motorcraft® TA-30 silicone sealant is crucial to ensure proper sealing and avoid appearance concerns.

NOTE: Driver door shown, passenger door similar.

FIGURE 99

- Remove the bungee cords used to hold the interior and exterior door handle cables up and seat the interior door handle cable rubber grommet.

- Reconnect the exterior door handle cable to the door handle, then lubricate the door handle cable end with XG-16 low temperature grease as shown in Figure 100.

FIGURE 100

- Install a new handle cable wiper clip on the exterior door handle cable end. See Figure 101.

FIGURE 101

- Reinstall the rear exterior door handles. Please follow the WSM procedures in Section 501-14.

NOTICE: Reinstall the exterior door handle cable and retaining clips in the original factory position.

- Clean any excessive silicone around the exterior door handle perimeter with isopropyl alcohol, Q-tips and a clean shop cloth to avoid appearance concerns.

Crew Cab vehicle repair is complete.

Rear Door Lower Latch Water Shield Kit Installation (F-150 Super Cab Vehicles With Safety Recall 17S33 Open)

NOTE: If the vehicle has previously had a rear lower door latch replaced, it may already have the latest level door latch water shield installed. If the Super Cab rear lower door latch has a large water shield installed as shown in Figure 105, then installation of a new water shield is not required.

NOTE: Procedure to be performed on both rear doors.

- Remove the rear door interior trim panels. Please follow the WSM procedures in Section 501-05.

- Remove the door panel weather shield for access. See Figure 102.

- Using compressed air, blow out any debris or residual water from the latch assembly area. See Figure 102.

FIGURE 102

- Inspect the interior door handle to latch cable for kinking. See Figure 104.

- Correct any kinks found in the cable by straightening the cable by hand as required.

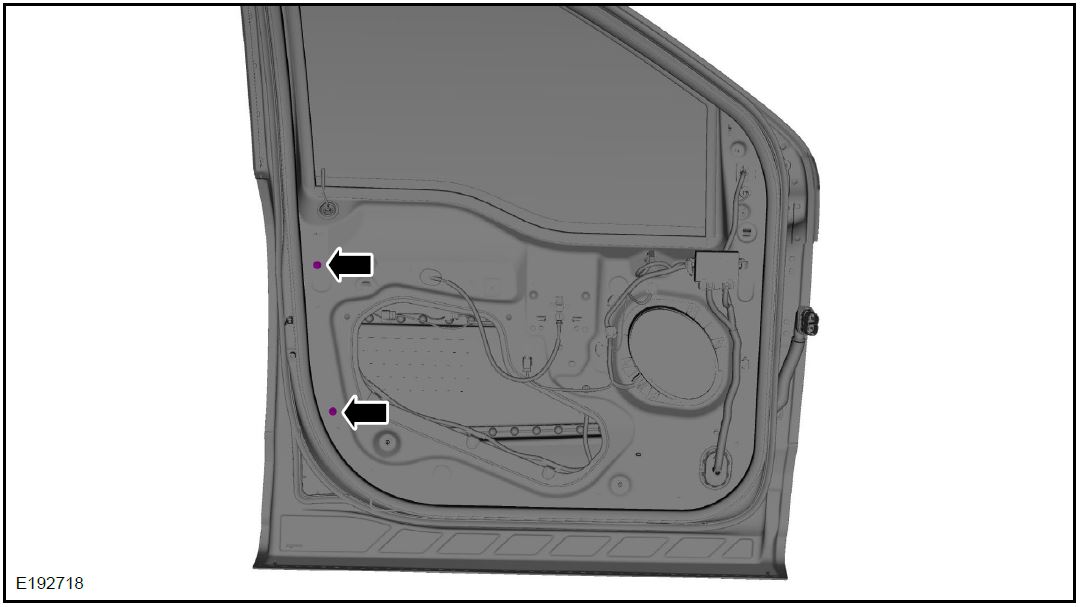

- Remove the three lower door latch bolts. See Figure 103.

FIGURE 103

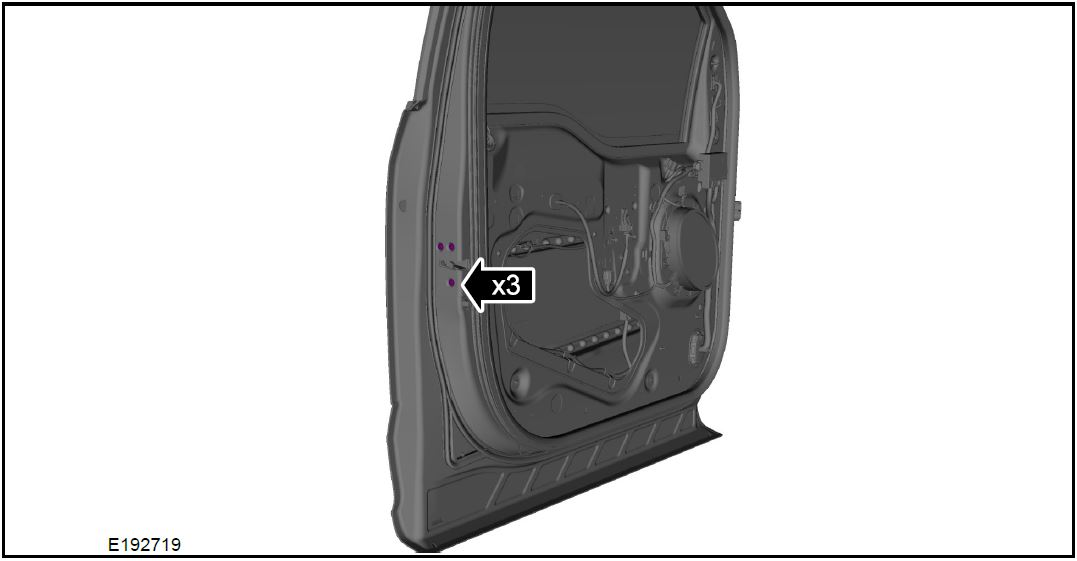

- Detach the cable retainers and disconnect the electrical connector. Position the rear door latch outside of the door. See Figure 104.

FIGURE 104

NOTE: Some F-150 SuperCab vehicles may be equipped with a smaller water shield than what is being installed in this program. The smaller shields must be removed and replaced. See Figure 105.

- If equipped with small water shields, remove and discard the existing lower door latch water shields.

See Figure 105.

FIGURE 105

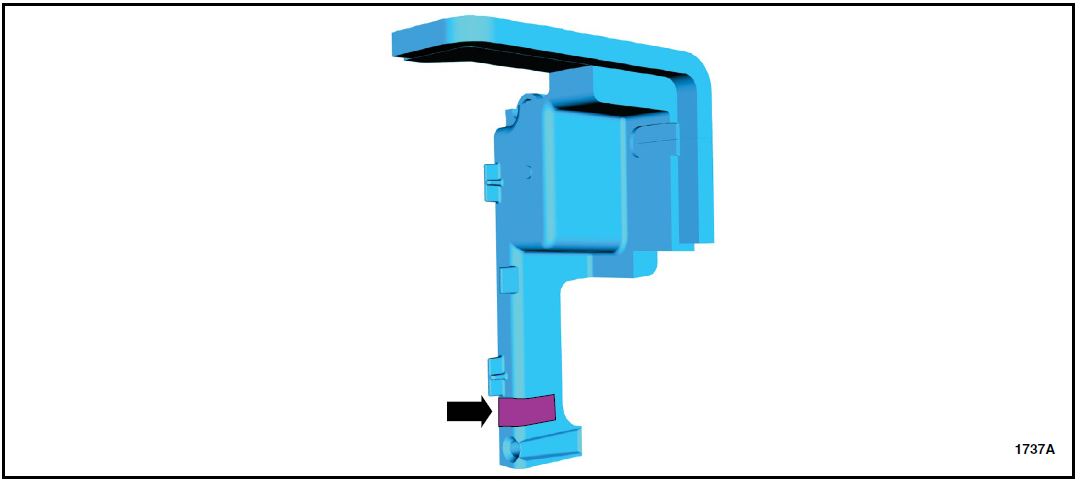

- Install a new door latch water shield onto the lower rear door latch. See Figure 106.

FIGURE 106

- Position the rear door lower latch back into the door. Attach the cable retainers and connect the electrical connector. See Figure 103.

- Install the three lower door latch bolts. See Figure 103.

- Torque 12 Nm (106 lb.in).

- Install the door panel weather shields. See Figure 102.

- Install the rear door interior trim panels. Please follow the WSM procedures in Section 501-05.

Super Cab vehicle repair is complete.

CERTAIN 2015-2018 MODEL YEAR F-150 AND 2017-2018 MODEL YEAR F-250 – F-550 VEHICLES — DOOR LATCH FREEZING CONCERNS

OVERVIEW

Some of the door foam kits were packaged with incorrect size door glass run funnels. Dealers are to measure the door glass run funnel wings using the measurement guide below. If a door foam kit is found to have incorrect size door glass run funnels the correct size door glass run funnels can be removed from another kit, and that additional kit the door glass run funnels were removed from can also be claimed with this repair. All unused parts from the additional kit can be scrapped.

NOTE: This packaging error caused rear doors foam kit FL3Z-16308-N to be incorrectly packaged with door glass run funnels from front doors foam kits FL3Z-16308-M. Conversely, the front doors foam kits FL3Z-16308-M were also incorrectly packaged with door glass run funnels from rear doors foam kit FL3Z-16308-N. If foam kits FL3Z-16308-M or FL3Z-16308-N are found to have incorrect funnels the correct funnels can likely be found in the other kit.

NOTE: This packaging error was corrected in December 2018.

SERVICE PROCEDURE – Door Glass Run Funnel Measurement Guide

Recommended Tool List:

| General Tools | Tape Measure |

- Verify the correct door glass funnels are being installed by measuring the funnel wings as shown in Figure 1.

NOTE: Funnel modification is not advised.

FIGURE 1

Customer Satisfaction Program 18N03 – Supplement #4

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles – Door Latch Freezing Concerns

INSTRUCTIONAL VIDEO LINKS

Video Links: F-150 shown, F-250-F-550 is similar.

IMPORTANT: Always refer to the dealer bulletin and the technical information for latest parts requirements and repair procedures.

NOTE: The procedures below are listed in the order they are shown in the technical information (Attachment III).

NOTE: Some videos show the same procedure performed on a vehicle as well as on a bench for demonstration purposes.

NOTE: The color of the grease used in the videos below may not reflect the color of the grease being used in the actual repair, as the required grease has been changed from XG-13 to XG-16 in most locations.

Video 1: Front Door Latch Water Shield Kit Installation – All F-150 Vehicles, If 17S33 Open

Video 2: Front Door Latch Rubber Water Shield Removal And Rubber Water Shield Retaining Pin Holes Sealing Procedure – All F-150 Vehicles, If Rubber Water Shield Present

Video 3: Front Door Glass Top Run And Outer Belt Moulding Sealing Procedure

Video 4: Door Glass Run Funnel And Door Glass Top Run Installation Procedure – Rear Door Shown, Front Door Similar

Video 5: Front Door Latch Sealing Procedure

Video 6: Exterior Door Handle Sealing Procedure – Rear Door Shown, Front Door Similar

Video 7: Rear Door Latch Water Shield Kit Installation – Crew Cab Vehicles, If 17S33 Open

Video 8: Rear Door Glass Top Run and Outer Belt Moulding Sealing Procedure

Video 9: Rear Door Latch Sealing Procedure

Video 10: Rear Door Lower Latch Water Shield Kit Installation – F-150 Super Cab Vehicles, If 17S33 Open

12 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| FORD | F-150 | 2015-2018 |

| FORD | F-250 SD | 2017-2018 |

| FORD | F-350 SD | 2017-2018 |

| FORD | F-450 SD | 2017-2018 |

| FORD | F-550 SD | 2017-2018 |

1 Associated Document

Manufacturer Communications

November 21, 2019

Customer Satisfaction Program 18N03 – Supplement #7

MC-10168821-0001.pdf 11633.742KB

Loading...

Loading...

NHTSA ID Number: 10159511

Manufacturer Communication Number: 18N03-S6

Summary

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles – Door Latch Freezing Concerns

1 Associated Document

Manufacturer Communications

April 23, 2019

Customer Satisfaction Program 18N03 – Supplement #6

MC-10159511-0001.pdf 10941.663KB

Loading...

Loading...

NHTSA ID Number: 10156537

Manufacturer Communication Number: 18N03-S5

Summary

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles – Door Latch Freezing Concerns

1 Associated Document

Manufacturer Communications

March 20, 2019

Customer Satisfaction Program 18N03 – Supplement #5

MC-10156537-0001.pdf 10606.263KB

Loading...

Loading...

NHTSA ID Number: 10156893

Manufacturer Communication Number: 18N03-S4

Summary

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles – Door Latch Freezing Concerns

1 Associated Document

Manufacturer Communications

February 20, 2019

Customer Satisfaction Program 18N03 – Supplement #4

MC-10156893-9999.pdf 10624.328KB

Loading...

Loading...

NHTSA ID Number: 10155581

Manufacturer Communication Number: 18N03-S4

Summary

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles – Door Latch Freezing Concerns

1 Associated Document

Manufacturer Communications

February 20, 2019

Customer Satisfaction Program 18N03 – Supplement #4

MC-10155581-9999.pdf 10624.328KB

Loading...

Loading...

NHTSA ID Number: 10153986

Manufacturer Communication Number: 18N03-S3

Summary

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles – Door Latch Freezing Concerns

1 Associated Document

Manufacturer Communications

January 8, 2019

Customer Satisfaction Program 18N03 – Supplement #3

Loading...

Loading...

NHTSA ID Number: 10153954

Manufacturer Communication Number: 18N03-S2

Summary

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles – Door Latch Freezing Concerns

1 Associated Document

Manufacturer Communications

December 19, 2018

Customer Satisfaction Program 18N03 – Supplement #2

MC-10153954-9999.pdf 10607.927KB

Loading...

Loading...

NHTSA ID Number: 10148744

Manufacturer Communication Number: 18N03-S1

Summary

Certain 2018 Model Year Expedition and Navigator Vehicles Equipped With R-1234yf Refrigerant – Special R-1234yf Refrigerant Service Information. Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 – Vehicles – Door Latch Freezing Concerns

1 Associated Document

Manufacturer Communications

October 12, 2018

Customer Satisfaction Program 18N03 – Supplement #1

Loading...

Loading...

NHTSA ID Number: 10149786

Manufacturer Communication Number: 18N03

Summary

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles – Door Latch Freezing Concerns

1 Associated Document

Manufacturer Communications

September 26, 2018

Customer Satisfaction Program 18N03

MC-10149786-9999.pdf 102.653KB

Loading...

Loading...

- Use on a variety of surfaces - metal, rubber, vinyl, plastic and more. Use on 100s of items like locks, chains, pulleys, hinges, valves, cables, etc.

- Professional- grade triple-action formula to lubricate and protect surfaces from natural elements

- No sticky residue, just a clear thin protective film that dries quickly to protect metal and non-metal surfaces

- Experts around the world trust WD-40 Specialist formula to deliver professional grade protection every single time

- Get more done with less effort - lubricate and protect virtually any kind of surface with one WD-40 Specialist formula

- Leaves no residue Regular maintenance with SALT TERMINATOR can prevent costly repairs & extend the life of vehicles, tools, gear & equipment.

- For use in gasoline, diesel, ethanol, & oil. Pour into fuel system, induce directly into combustion chamber via main manifold vacuum line and add to crankcase.

- Wood, metal and rubber surfaces. Use in moist and harsh environments. Not for use as an appearance cleaner or on paint.

- Flushes marine engines, cooling systems, heat exchanges; Cleans & Protects boats, PWCs, trailers, gear, fishing tackle, autos, RVs, trucks, tools, motorcycles, atvs, bicycles, patio furniture & more!

- 3-Pack of DuPont silicone lubricant

- A clean, light-duty product, DuPont silicone lubricant is excellent for non-metal materials that may be damaged by conventional lubricants

- Waterproofs, protects, lubricates and preserves

- Eliminates squeaking and binding in windows, hinges, locks, etc.

- Helps prevent rust, oxidation and corrosion on all metals

- DuPont Silicone Lubricant with Teflon Fluoro Polymer

- A clean, light-duty product, DuPont Silicone Lubricant with Teflon Fluoropolymer is excellent for non-metal materials that may be damaged by conventional lubricants

- Waterproofs, protects, lubricates and preserves

- For use on rubber, plastic, vinyl, leather, metal and wood

- Eliminates squeaking and binding in windows, hinges, locks, etc.

- Will not mar paint, rubber or plastic surfaces

- Electrically insulates, lubricates and waterproofs all types of mechanical equipment

- Coats hinges and channels, preventing locks, doors and windows from binding and squeaking

- High silicone formula does not attract dust or dirt

- Protects and renews rubber mountings, bushings and weather stripping

- PERFECT BUNDLE SET - This set includes 1x Blaster Silicone Lubricant Spray bundle with 1x Microfiber Cloth, ensuring smooth application and helping to evenly distribute the lubricant on surfaces for optimal performance. (Packaging May Vary)

- LONG-LASTING LUBRICATION - Blaster Silicone Lubricant delivers extended lubrication, ensuring that your equipment runs smoothly over time. Its clear, non-evaporating formula provides durable protection even under constant use.

- ENHANCES EQUIPMENT PERFORMANCE - Improve the performance of various mechanical components such as bearings, bushings, and chains. This silicone lubricant reduces friction, allowing for smoother, more efficient operation.

- PREVENTS WEAR AND DAMAGE - The non-staining formula helps to reduce wear caused by constant friction. It protects vital equipment components from premature damage, extending their lifespan.

- VERSATILE APPLICATIONS - Ideal for a wide variety of surfaces and equipment, including window and door seals, lawn tools, pulleys, winches, sports gear, and more. Perfect for both household and outdoor use.

- Lubricates and eliminates squeaking and binding caused by friction.

- Film is clean and highly resistant to water.

- Use on nylon, rubber, metal and non-metal surfaces.

- Perfect for applications exposed to the elements

- Multi-Use Silicone Spray

- Specially formulated to lubricate, waterproof slide-outs

- It’s quick drying, long lasting and safe to use on metal, rubber, vinyl, and plastic

- Keeps any slide-out running smoothly without sticking or squeaking

- Prevent rust and corrosion on all types of slide-out mechanisms

- Permanent SMART STRAW SPRAYS 2 WAYS nozzle offers more control. Spray or stream and Never Lose the Straw Again

- CRC INDUSTRIES: A market leader that offers impeccably designed chemical solutions to maintain, protect and repair different marine, heavy-duty motor vehicles, industrial-grade engines, household tools and electrical equipment.

- WATER BASED SILICONE LUBRICANT: This heavy-duty silicone lubricant is non-flammable and NSF H1 registered for incidental food contact. Eliminates sticking and binding and is safe to use on most surfaces.

- PERMA LOCK: The CRC Perma-Lock 2-Way integrated actuator features a dual-purpose design that gives you both broad spray and precision spraying options through the convenient locked-in-place straw.

- APPLICATIONS: This water-based lubricant is ideal for use in food processing and handling equipment, chutes, guides, rails, conveyors, bottling machinery, ovens, freezers, linkages, locks, pulleys, timers, rubber seals, tools, and ceramic insulators.

- PRODUCT SPECIFICATIONS: Available in a 13 wt. oz. aerosol can.

SEOCONTENT-START

Copyright 2019 Ford Motor Company

David J. Johnson Ford Motor Company

Director P. O. Box 1904

Service Engineering Operations Dearborn, Michigan 48121

Ford Customer Service Division

November 21, 2019

TO: All U.S. Ford and Lincoln Dealers

Dealers

SUBJECT: Customer Satisfaction Program 18N03 – Supplement #7

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550

Vehicles – Door Latch Freezing Concerns

REF: Customer Satisfaction Program 18N03 – Supplement #6

Dated April 23, 2019

REF:

NEW VEHICLE DEMONSTRATION / DELIVERY HOLD – Safety Recall 17S33

Certain 2015-2017 Model Year F-150 and 2017 Model Year F-Super Duty Vehicles

Doors Will Not Close or Open While Driving

PROGRAM TERMS

This is a one-time repair program for vehicle owners that report a door latch freezing concern.

Affected vehicles are eligible for this repair through October 31, 2028, regardless of vehicle mileage or

warranty start date. Coverage is automatically transferred to subsequent owners. This program will

expire October 31, 2028.

New! REASON FOR THIS SUPPLEMENT

Technical Information: Updated with revised directions regarding the inspection of the interior door

handle release cables. As a result, the Labor Allowances and the Parts Requirements / Ordering

Information have also been updated.

VEHICLES COVERED BY THIS PROGRAM

Vehicle Model Year Assembly Plant Build Dates

F-150 2015-2018

Dearborn March 12, 2014 through April 12, 2018

Kansas City August 11, 2014 through April 3, 2018

F-250 – F-550 2017-2018

Kentucky October 8, 2015 through April 21, 2018

OHAP February 5, 2016 through April 17, 2018

Affected vehicles are identified in OASIS.

REASON FOR PROVIDING EXTENDED WARRANTY COVERAGE

In the affected vehicles, water entering the doors in cold temperatures can cause door latching

components to freeze. Ford is offering this no charge service to customers that have experienced a

frozen door latch to install additional sealing to the front doors and crew cab rear doors, which will

prevent water intrusion and door latch freezing.

Copyright 2019 Ford Motor Company

SERVICE ACTION

If an affected vehicle owner has reported a frozen latch concern, dealers are to install additional

sealing to the front doors and crew cab rear doors, lubricate certain door latch, door handle and cable

components, clean the door drain holes, inject windshield wash concentrate or a methyl hydrate

(methanol) product into the exterior door handle cables and install a wiper clip on the exterior door

handle cable ends. This service must be performed at no charge to the vehicle owner.

Note: The technical instructions for this program include all additional steps required to also

complete safety recall 17S33, if 17S33 is open.

OWNER NOTIFICATION MAILING SCHEDULE

Owners of affected vehicles have been notified. Dealers should repair any affected vehicles that

experience a frozen door latch whether or not the customer has received a letter.

New! ATTACHMENTS

Attachment I: Administrative Information

Attachment II: Labor Allowances and Parts Ordering Information

Attachment III: Technical Information

Attachment IV: Instructional Video Links

Attachment V: Door Glass Run Funnel Measurement Guide

Owner Notification Letters

QUESTIONS & ASSISTANCE

For questions and assistance, contact the Special Service Support Center (SSSC) via the SSSC Web

Contact Site. The SSSC Web Contact Site can be accessed through the Professional Technician

Society (PTS) website using the SSSC link listed at the bottom of the OASIS VIN report screen or

listed under the SSSC tab.

Sincerely,

David J. Johnson

Copyright 2019 Ford Motor Company

ATTACHMENT I

Page 1 of 2

Customer Satisfaction Program 18N03 – Supplement #7

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles

Door Latch Freezing Concerns

OASIS ACTIVATION

OASIS was activated on September 26, 2018.

FSA VIN LISTS ACTIVATION

FSA VIN Lists was not activated for this service action.

SOLD VEHICLES

• Only owners with affected vehicles that exhibit the covered condition will be directed to dealers

for repairs.

• Dealers are to prioritize repairs of customer vehicles over repairs of new and used vehicle

inventory.

STOCK VEHICLES

Do not perform this program unless the affected vehicle exhibits the covered condition.

TITLE BRANDED / SALVAGED VEHICLES

Affected title branded and salvaged vehicles are eligible for this service action.

OWNER REFUNDS

Refunds are not approved for this program.

RENTAL VEHICLES

The use of rental vehicles is not approved for this program.

ADDITIONAL REPAIR (LABOR TIME AND/OR PARTS)

Additional repairs identified as necessary to complete the FSA should be managed as follows:

• For related damage and access time requirements, refer to the Warranty and Policy Manual –

Section 6 – Ford & Lincoln Program Policies / General Information & Special Circumstances

Program Policies / General Information & Special Circumstances

for FSA’s / Related Damage.

• For vehicles within new vehicle bumper-to-bumper warranty coverage, no SSSC approval is

required.

o Ford vehicles – 3 years or 36,000 miles

• For vehicles outside new vehicle bumper-to-bumper warranty coverage, submit an Approval

Request to the SSSC Web Contact Site prior to completing the repair.

Copyright 2019 Ford Motor Company

ATTACHMENT I

Page 2 of 2

Customer Satisfaction Program 18N03 – Supplement #7

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles

Door Latch Freezing Concerns

CLAIMS PREPARATION AND SUBMISSION

• Claim Entry: Enter claims using Dealer Management System (DMS) or One Warranty

Solution (OWS) online.

o When entering claims, select claim type 31: Field Service Action. The FSA number

18N03 is the sub code.

o For additional claims preparation and submission information, refer to the Recall and

Customer Satisfaction Program (CSP) Repairs in the OWS User Guide.

• Related Damage/Additional labor and/or parts: Must be claimed as Related Damage on a

separate repair line from the FSA with same claim type and sub code as described in Claim

Entry above.

IMPORTANT: Click the Related Damage Indicator radio button.

• Provision for Locally Obtained Supplies: Includes XG-11, XG-13, XG-16, XL-6, TA-30, Cotton

Swabs/Q-Tips®, Isopropyl Alcohol, brushes, syringe, eye dropper or a similar applicator and

Motorcraft® Premium Windshield Wash Concentrate (ZC-32-B2) or a 99 percent Methyl

Hydrate (Methanol) product.

NOTE: The listed chemicals and locally obtained supplies can be used on multiple vehicles.

o Program Code: 18N03

o Misc Expense: OTHER

o Amount: Actual cost up to $12.00

• PROGRAM TERMS: This program will be in effect through October 31, 2028. There is no

mileage limit for this program.

• Claims with labor operation code 18N03B, 18N03C, 18N03D, 18N03E, 18N03F, 18N03G or

18N03H must have a repair date on or before January 8, 2019 to be eligible for payment.

• Claims with labor operation code 18N03J, 18N03K, 18N03L, 18N03M, 18N03N, 18N03O or

18N03P must have a repair date on or before February 20, 2019 to be eligible for payment.

• Claims with labor operation code 17S33F, 17S33G, 17S33H or 17S33J must have a repair

date on or before April 23, 2019 to be eligible for payment.

Copyright 2019 Ford Motor Company

ATTACHMENT II

Page 1 of 3

Customer Satisfaction Program 18N03 – Supplement #7

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles

Door Latch Freezing Concerns

New! LABOR ALLOWANCES

Only 18N03 open:

Description Labor Operation Labor Time

Install Front Door Latch Sealing (All Regular Cab) 18N03Q 2.0 Hours

Install Front Door Latch Sealing (All Super Cab) 18N03R 2.0 Hours

Install Front and Rear Door Latch Sealing (All Crew Cab) 18N03S 3.7 Hours

Additional time to allow for obtaining the correct door glass run

funnels, if a kit is found to be packaged with incorrect funnels.

This labor operation can be used in combination with any 18N03

operations except MT18N03.

18N03Z 0.1 Hours

* Additional Time For Replacement Of Interior Door Handle

Release Cable(s) – Only if an interior door handle release cable

is found to be kinked.

This labor operation can be used in combination with any 18N03

operations except 18N03Z.

MT18N03

0.6 Hours Per Affected Door

(Up To 2.4 Hours for 4 doors on

a crew cab)

* Less than 5% vehicles are expected to require a cable replacement.

Both 18N03 and Safety Recall 17S33 open:

NOTE: The following labor operations include incremental time for performing 18N03 when

performing safety recall 17S33 is also required. Both 18N03 and 17S33 labor operations must be

claimed on the same repair order, but separate repair order lines.

NOTE: The 17S33 labor operation must be claimed using 17S33 as the sub code. Refer to the

17S33 dealer bulletin for complete 17S33 claiming instructions and part requirements.

Description Labor Operation Labor Time

Install Front Door Latch Shields (F-150 Regular Cab)*

Install Front Door Latch Sealing (F-150 Regular Cab)

Claim both labor operations on separate repair lines

17S33K 1.1 Hours

18N03T 1.6 Hours

Install Front and Rear Door Latch Shields (F-150 Super Cab)*

Install Front Door Latch Sealing (F-150 Super Cab)

Claim both labor operations on separate repair lines

17S33M 1.8 Hours

18N03U 1.6 Hours

Install Front and Rear Door Latch Shields (F-150 Crew Cab)*

Install Front and Rear Door Latch Sealing (F-150 Crew Cab)

Claim both labor operations on separate repair lines

17S33L 1.8 Hours

18N03V 3.0 Hours

Install Rear Door Latch Shields (F-250-F-550 Crew Cab)*

Install Front and Rear Door Latch Sealing (F-250-F-550 Crew

Cab)

Claim both labor operations on separate repair lines

17S33N 0.9 Hours

18N03W 3.4 Hours

* Includes time to replace lock rods and transfer buttons and grommets as needed.

Labor Allowances Continued On The Next Page

Copyright 2019 Ford Motor Company

ATTACHMENT II

Page 2 of 3

Customer Satisfaction Program 18N03 – Supplement #7

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles

Door Latch Freezing Concerns

New! LABOR ALLOWANCES (continued)

Both 18N03 and Safety Recall 17S33 open:

Description Labor Operation Labor Time

** Additional Time For Replacement Of Interior Door Handle

Release Cable(s) – Only if an interior door handle release cable

is found to be kinked.

This labor operation can be used in combination with any 18N03

operations.

MT18N03

0.6 Hours Per Affected Door (Up

To 2.4 Hours for 4 doors on a

crew cab)

** Less than 5% vehicles are expected to require a cable replacement.

New! PARTS REQUIREMENTS / ORDERING INFORMATION

Part Number Description Order

Quantity

Claim

Quantity

FL3Z-16308-L Front Doors Foam Kit (F-150 Built Prior to

December 2016*) As required

FL3Z-16308-P (New Kit)***

FL3Z-16308-M (Old Kit)***

Front Doors Foam Kit (F-150 Built December

2016 or later and All F-Super Duty*) As required

FL3Z-16308-Q (New Kit)***

FL3Z-16308-N (Old Kit)*** Rear Doors Foam Kit (crew cab only) As required

LL3Z-15264B28-A Exterior Door Handle Cable Wiper Clip

(One Piece per Package)

2 Req. Reg/Sup Cab

4 Req. Crew Cab

XG-16 Motorcraft® Low Temperature Grease**

MISC. OTHER

XG-13 Motorcraft® Door Latch Grease**

XG-11 Motorcraft® High Temperature Grease**

XL-6 Motorcraft® Silicone Spray**

TA-30 Motorcraft® Silicone Sealant**

ZC-32-B2

Motorcraft® Premium Windshield Wash

Concentrate, or a 99 percent Methyl Hydrate

(Methanol) product**

Obtain Locally

Cotton Swabs/Q-Tips®**

Isopropyl Alcohol**

Brushes**

Syringe, Eye Dropper or a Similar Applicator

All parts are now available for ope n ordering.

* Front door foam kit build date usages are approximations.

** The listed chemicals and locally obtained supplies can be used on multiple vehicles.

*** Either kit can be used. The new kits have the correct funnels, and old kits require funnel

verification.

Parts Requirements / Ordering Information Continued On The Next Page

Copyright 2019 Ford Motor Company

ATTACHMENT II

Page 3 of 3

Customer Satisfaction Program 18N03 – Supplement #7

Certain 2015-2018 Model Year F-150 and 2017-2018 Model Year F-250-F-550 Vehicles

Door Latch Freezing Concerns

New! PARTS REQUIREMENTS / ORDERING INFORMATION (continued)

Part Number Description Order

Quantity

Claim

Quantity

HC3Z-15221A00-B (RH

Front – All Vehicles Except

F-150 with Gas Engine)

Interior Door Handle Release Cable As required ****

HC3Z-15221A01-B (LH

Front – All Vehicles Except

F-150 with Gas Engine)

FL3Z-15221A00-B (LH/RH

Front – Only F-150 with Gas

Engine)

FL3Z-1540180-A (LH/RH

Rear – All Vehicles Crew

Cab Doors)

**** Less than 5% vehicles are expected to require a cable replacement.

NOTE: Up to one of each of the “old” door foam kits can be claimed with each 18N03 repair,

regardless of cab style and vehicle build date. If a door foam kit is found to have incorrect size door

glass run funnels the correct size door glass run funnels can be removed from another kit, and that

additional kit the door glass run funnels were removed from can be claimed with this repair. All

unused parts of the additional kit can be scrapped. The “new” door foam kits always include the

correct funnels, and therefore when “new” door foam kits are being used only the prescribed parts

based on cab style and build date can be claimed.

Order your parts requirements through normal order processing channels. To guarantee the shortest

delivery time, an emergency order for parts must be placed.

NOTE: Additional parts required to complete safety recall 17S33, if required, are listed in the 17S33

dealer bulletin.

DEALER PRICE

For latest prices, refer to DOES II.

PARTS RETENTION AND RETURN

Follow the provisions of the Warranty and Policy Manual, Section 1 – WARRANTY PARTS

RETENTION AND RETURN POLICIES.

EXCESS STOCK RETURN

Excess stock returned for credit must have been purchased from Ford Customer Service Division in

accordance with Policy Procedure Bulletin 4000.

ATTACHMENT III

PAGE 1 OF 72

CUSTOMER SATISFACTION PROGRAM 18N03-S7

CPR © 2019 FORD MOTOR COMPANY

DEARBORN, MICHIGAN 48121

11/2019

CERTAIN 2015-2018 MODEL YEAR F-150 AND 2017-2018 MODEL YEAR F-250 –

F-550 VEHICLES — DOOR LATCH FREEZING CONCERNS

OVERVIEW

In the affected vehicles, water entering the doors in cold temperatures can cause door latching

components to freeze. Ford is offering this no charge service to customers that have experienced a

frozen door latch to install additional sealing to the front doors and crew cab rear doors, which will prevent

water intrusion and door latch freezing. If an affected vehicle owner has reported a frozen latch concern,

dealers are to install additional sealing to the front doors and crew cab rear doors, and lubricate certain

door latch, door handle and cable components. This service must be performed at no charge to the

vehicle owner.

NOTE: The technical instructions for this program include all additional steps required to also complete

safety recall 17S33, if 17S33 is open.

NOTE: Please read this procedure in its entirety, prior to performing repairs. Additionally, instructional

videos have been developed to assist with the repair. Please refer to ATTACHMENT IV –