| “This site contains affiliate links for which OEMDTC may be compensated” |

May 29, 2014 NHTSA CAMPAIGN NUMBER: 14V284000

Loss of Electric Power Steering Assist

If power steering assist is lost, greater driver effort would be required to steer the vehicle at low speeds, increasing the risk of a crash.

NHTSA Campaign Number: 14V284

Manufacturer Ford Motor Company

Motor Company

Components STEERING

Potential Number of Units Affected 740,878

Summary

Ford Motor Company (Ford

Motor Company (Ford ) is recalling certain model year 2008-2011 Ford

) is recalling certain model year 2008-2011 Ford Escape and Mercury

Escape and Mercury Mariner vehicles manufactured August 18, 2006, through September 11, 2010. The affected vehicles have a steering torque sensor that may not be able to properly detect driver steering input. As a result, the system could remove the Electric Power Steering (EPS) assist.

Mariner vehicles manufactured August 18, 2006, through September 11, 2010. The affected vehicles have a steering torque sensor that may not be able to properly detect driver steering input. As a result, the system could remove the Electric Power Steering (EPS) assist.

Remedy

Ford will notify owners, and dealers will update the software for the power steering control module (PSCM) and the instrument cluster module, free of charge. If a vehicle shows a history of a loss of the torque sensor signal or fault codes relating to the PSCM when the vehicle is brought in for the recall remedy, the affected components will be replaced, free of charge. The recall began on July 18, 2014. Owners may contact Ford

will notify owners, and dealers will update the software for the power steering control module (PSCM) and the instrument cluster module, free of charge. If a vehicle shows a history of a loss of the torque sensor signal or fault codes relating to the PSCM when the vehicle is brought in for the recall remedy, the affected components will be replaced, free of charge. The recall began on July 18, 2014. Owners may contact Ford customer service at 1-800-392-3673. Ford

customer service at 1-800-392-3673. Ford ’s number for this recall is 14S05.

’s number for this recall is 14S05.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

AFFECTED VEHICLES

Certain 2008-2011 model year Escape and Mariner vehicles built at the Kansas City Assembly Plant from Job #1 2008 through September 11, 2010. Affected vehicles are identified in OASIS. In addition, for a list of vehicles assigned to your dealership, visit https://web.fsavinlists.dealerconnection.com. This information was available on May 29, 2014.

REASON FOR THIS SAFETY RECALL

In some of the affected vehicles, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor. In manual steering mode there is still a mechanical linkage between the steering wheel and the road wheel, allowing steering control to be maintained. If this condition should occur, the steering effort may be greater at low speeds, which may increase the risk of accident.

SERVICE ACTION

Dealers are to check the Power Steering Control Module (PSCM) for Diagnostic Trouble Codes (DTCs).

- If DTC B1342, B2277, or B2278 are NOT present, reprogram the PSCM and the Instrument Cluster (IC) module.

- If only DTC B2278 is present, replace the torque sensor.

- If DTC B1342 or B2277 is present, replace the steering column assembly.

NOTE: The software to perform the repair is currently not available to support Safety Recall 14S05, but will be released on July 9, 2014. Until IDS release 91.02 is available, customer vehicles should be repaired only if the vehicle arrives at your dealership with a customer complaint of loss of steering assist accompanied by one of the DTCs noted above.

One of the above services must be performed on all affected vehicles at no charge to the vehicle owner.

Dealership service management must provide a copy of the Customer Information Sheet (posted with this bulletin) to the owners of all vehicles that had modules reprogrammed (did not receive a replacement torque sensor or steering column). This Customer Information Sheet provides information on the warnings that may now display on the instrument cluster message center.

OWNER NOTIFICATION MAILING SCHEDULE

Owner Letters are expected to be mailed the week of July 14, 2014. Dealers should repair any affected vehicles that arrive at their dealerships, whether or not the customer has received a letter.

STOCK VEHICLES

Use OASIS to identify any affected vehicles in your used vehicle inventory.

SOLD VEHICLES

- Owners of affected vehicles will be directed to dealers for repairs.

- Immediately contact any of your affected customers whose vehicles are not on your VIN list but are identified in Give the customer a copy of the Owner Notification Letter (when available) and schedule a service date.

- Correct other affected vehicles identified in OASIS which are brought to your dealership.

TITLE BRANDED / SALVAGED VEHICLES

Affected title branded and salvaged vehicles are eligible for this recall.

RELATED DAMAGE

If a related damage condition exists that you believe to be caused by the covered condition, call the Special Service Support Center to request approval prior to the repair of any related damage.

Requests for approval after completion of the repair will not be granted. Ford Motor Company reserves the right to deny coverage for related damage in cases where the vehicle owner has not had this recall performed on a timely basis. Additional related damage parts are subject to random selection for return to the Ford

Motor Company reserves the right to deny coverage for related damage in cases where the vehicle owner has not had this recall performed on a timely basis. Additional related damage parts are subject to random selection for return to the Ford Warranty Parts Analysis Center (WPAC).

Warranty Parts Analysis Center (WPAC).

OWNER REFUNDS

- This safety recall must still be performed, even if the owner has paid for a previous Claiming a refund will not close the recall on the vehicle.

- Ford

Motor Company is offering a refund for owner-paid repairs covered by this recall if the repair was performed prior to the date indicated in the reimbursement plan, which is posted with this Owners are directed to seek reimbursement through authorized dealers or, at their option, directly through Ford

Motor Company is offering a refund for owner-paid repairs covered by this recall if the repair was performed prior to the date indicated in the reimbursement plan, which is posted with this Owners are directed to seek reimbursement through authorized dealers or, at their option, directly through Ford Motor Company at P.O. Box 6251, Dearborn, MI 48121- 6251.

Motor Company at P.O. Box 6251, Dearborn, MI 48121- 6251. - Dealers are also authorized to refund owner-paid emergency repairs that were performed away from an authorized servicing dealer after the end date specified in the reimbursement Non-covered repairs, or those judged by Ford

to be excessive, will not be reimbursed.

to be excessive, will not be reimbursed. - Refunds will only be provided for the cost associated with steering column or torque sensor replacement for loss of steering assist.

RENTAL VEHICLES

If a customer’s vehicle requires the replacement of the steering column or torque sensor and it is necessary to order parts, Ford Motor Company will pay for one day of vehicle rental. Follow Extended Service Plan (ESP) guidelines for dollar amounts. The daily rate can include applicable taxes but is not allowed to exceed the stated daily rate. Rentals will only be reimbursed for the day the vehicle is at the dealership for part replacement. Prior approval for more than one rental day is required from the Special Service Support Center (1-800-325-5621). The parts order must be an emergency order (unit down) to guarantee the shortest delivery time.

Motor Company will pay for one day of vehicle rental. Follow Extended Service Plan (ESP) guidelines for dollar amounts. The daily rate can include applicable taxes but is not allowed to exceed the stated daily rate. Rentals will only be reimbursed for the day the vehicle is at the dealership for part replacement. Prior approval for more than one rental day is required from the Special Service Support Center (1-800-325-5621). The parts order must be an emergency order (unit down) to guarantee the shortest delivery time.

PARTS REQUIREMENTS

Torque Sensor

| Part Number | Description | Quantity |

|---|---|---|

| CL8Z-3F818-A | Torque Sensor | 1 |

| W712250–S437 | Upper Column Bolt | 2 |

Steering Column Assembly

| Part Number | Description | Quantity |

|---|---|---|

| CL8Z-3C529-C | Steering Column Assembly | 1 |

| W713065-S439 | Steering Column Coupling-to-Steering Gear Bolt | 1 |

| W712250–S437 | Upper Column Bolt | 2 |

Safety Recall 14S05

Certain 2008-2011 Model Year Escape and Mariner Vehicles

Electric Power Steering

DEALER Q & A

Q1. What is the problem?

Ford is voluntarily recalling certain 2008-2011 model year Escape and Mariner vehicles to address concerns relating to power steering operation. In some of the affected vehicles, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor. In manual steering mode there is still a mechanical linkage between the steering wheel and the road wheel, allowing steering control to be maintained. If this condition should occur, the steering effort may be greater at low speeds, which may increase the risk of accident.

is voluntarily recalling certain 2008-2011 model year Escape and Mariner vehicles to address concerns relating to power steering operation. In some of the affected vehicles, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor. In manual steering mode there is still a mechanical linkage between the steering wheel and the road wheel, allowing steering control to be maintained. If this condition should occur, the steering effort may be greater at low speeds, which may increase the risk of accident.

Q2. Why are some vehicles repaired through part replacement and others repaired through module reprograming?

Each of these repairs mitigates the safety risk associated with this recall. The replacement torque sensor and steering column have improved durability to prevent the condition that results in loss of steering assist. Reprograming the modules will prevent the sudden loss of steering assist while driving, will display a warning light or message, and a chime will sound to inform the driver.

Q3. What does the software updates do?

The software updates may extend the time steering assist is maintained. In addition, the update provides increased driver awareness by sounding a chime and displaying the wrench light or warning in the message center when a fault is detected.

Q4. What if a customer experiences loss of steering assist after the modules have been reprogrammed?

The modules were reprogrammed to prevent sudden loss of steering assist while driving. Additionally, the instrument cluster software update will provide audible and visual indications to the driver in the unlikely event of a torque sensor fault. Any subsequent loss of assist repairs experienced after completion of module reprogramming are not covered by this recall.

Q5. What should I tell a customer who experiences loss of steering assist after the recall has been performed?

The modules were reprogrammed to prevent sudden loss of steering assist while driving in the event of a torque sensor fault. Customers should be advised that the replacement of the steering column or torque sensor is at their expense.

CERTAIN 2008-2011 MODEL YEAR ESCAPE AND MARINER VEHICLES — ELECTRIC POWER STEERING

OVERVIEW

In some of the affected vehicles, the power steering system may revert to manual steering mode due to an Electric Power Steering (EPS) system fault related to the torque sensor. In manual steering mode there is still a mechanical linkage between the steering wheel and the road wheel, allowing steering control to be maintained. If this condition should occur, the steering effort may be greater at low speeds, which may increase the risk of accident.

SERVICE PROCEDURE

- Connect IDS and check for Diagnostic Trouble Codes (DTCs) in the Power Steering Control Module (PSCM).

- If DTC B1342, B2277, or B2278 are NOT present, reprogram the PSCM and the Instrument Cluster (IC) Proceed to “Module Reprogramming” on Page 2.

- If only DTC B2278 is present, replace the torque Proceed to “Torque Sensor Replacement” on Page 4.

- If DTC codes B1342 or B2277 are present, replace the steering column. For additional information, refer to Workshop Manual (WSM) Section 211-04.

NOTE: None of the modules need to be reprogrammed if the torque sensor or the steering column is replaced.

Important Information for Module Programming

NOTE: When programming or reprogramming a module, use the following basic checks to ensure programming completes without errors.

- Make sure the 12V battery is fully charged before carrying out the programming steps and connect IDS/scan tool to a power source.

- Inspect Vehicle Communication Module (VCM) and cables for any Make sure scan tool connections are not interrupted during programming.

- A hardwired internet connection is strongly recommended.

- Turn off all unnecessary accessories (radio, heated/cooled seats, head lamps, interior lamps, HVAC system, etc.) and close doors.

- Disconnect/depower any aftermarket accessories (remote start, alarm, power inverter, CB radio, ).

- Follow all scan tool on-screen instructions carefully.

- Disable IDS/scan tool sleep mode, screensaver, hibernation modes.

- Create all sessions Key On Engine Off (KOEO). Starting the vehicle before creating a session will cause errors within the programming inhale process.

Module Reprogramming

NOTE: Reprogram appropriate vehicle modules before performing diagnostics and clear all Diagnostic Trouble Codes (DTCs) after programming. For DTCs generated after reprogramming, follow normal diagnostic service procedures.

- Reprogram the PSCM and IC module using IDS release 91.02 or higher.

NOTE: All PSCMs require an update, but only some IC modules require an update.

NOTE: Calibration files may also be obtained at www.motorcraft.com.

NOTE: Follow the IDS on-screen instructions to complete the reprogramming procedure.

Recovering a module when programming has resulted in a blank module:

NEVER DELETE THE ORIGINAL SESSION!

- a. Obtain the original IDS that was used when the programming error occurred during Module Reprogramming (MR) or Programmable Module Installation (PMI).

- b. Disconnect the VCM from the data link connector (DLC) and the IDS.

- c. Reconnect the VCM to IDS and then connect to the Once reconnected, the VCM icon should appear in the corner of the IDS screen. If it does not, troubleshoot the IDS to VCM connection.

- d. Locate the ORIGINAL vehicle session when programming This should be the last session used in most cases. If not, use the session created on the date that the programming failed.

NOTE: If the original session is not listed in the previous session list, click the ”Recycle Bin” icon at the lower right of the previous session screen. This loads any deleted sessions and allows you to look through them. Double-click the session to restore it.

- e. Once the session is loaded, the failed process should resume automatically.

- f. If programming does not resume automatically, proceed to the Module Programming menu and select the previously attempted process, PMI or MR.

- g. Follow all on-screen prompts/instructions.

- h. Near the end of programming, the IDS prompts you to select certain It is important to make a selection for ALL parameters listed. If the correct selection is already highlighted, you must still choose that selection before clicking the “Tick” mark to complete the configuration.

- i. The last screen on the IDS may list additional steps required to complete the programming process. Make sure all applicable steps listed on the screen are followed in order.

Torque Sensor Replacement

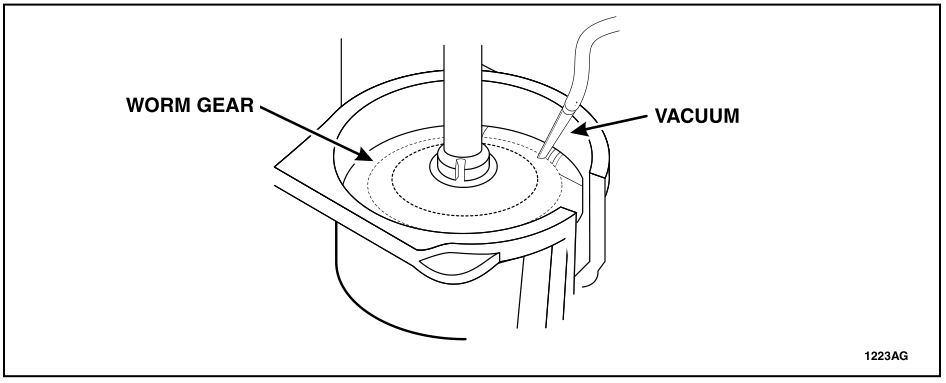

NOTE: This procedure must take place in a clean environment to ensure no contamination enters the worm gear.

NOTE: For clarity, some illustrations show an orientation different from the actual work perspective.

- With the vehicle in NEUTRAL, position it on a hoist. For additional information, refer to WSM Section 100-02.

- For ease of assembly, turn the steering wheel to the 11:00 o’clock position.

- Hybrid vehicles: Depower the high-voltage traction For additional information, refer to WSM Section 414-03.

- Disconnect the 12V For additional information, refer to WSM Section 414-01.

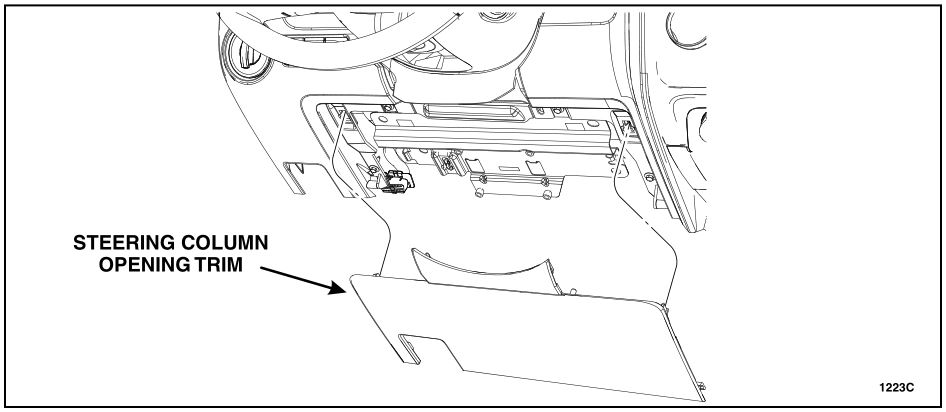

- Remove the steering column opening trim. See Figure 1.

Figure 1

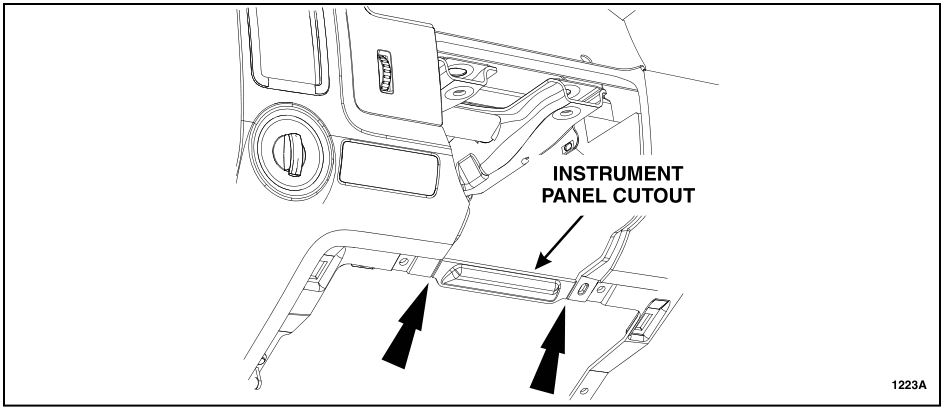

- If present, use a suitable cutting tool to carefully cut through the two cutoff lines and discard the instrument panel cutout. See Figure 2.

NOTE: Steering column removed for clarity.

Figure 2

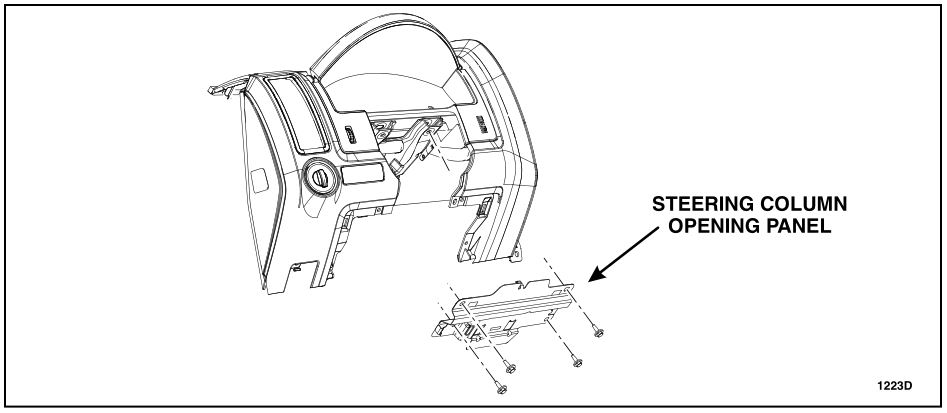

- Remove the four bolts and the steering column opening panel. See Figure 3.

NOTE: Steering column removed for clarity.

Figure 3

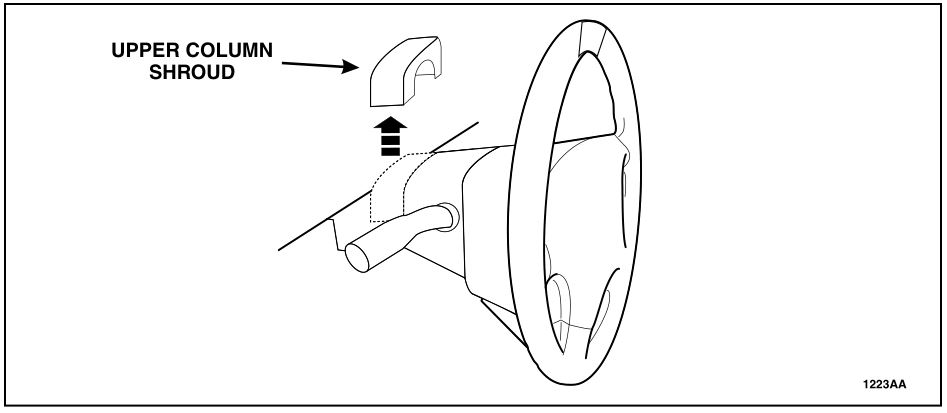

- Pull up and remove the upper column shroud. See Figure 4.

Figure 4

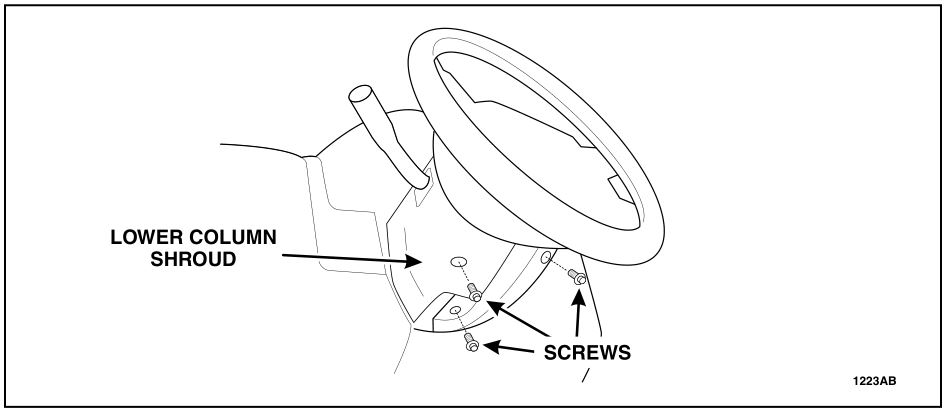

Remove the three machine screws and the lower column shroud. See Figure 5.

Figure 5

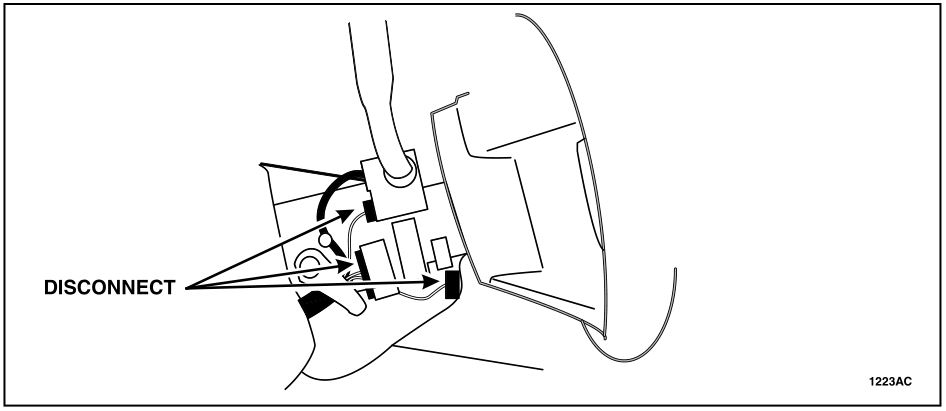

- Disconnect the three connectors on the left side of the column. Remove the two harness pin-type See Figure 6.

Figure 6

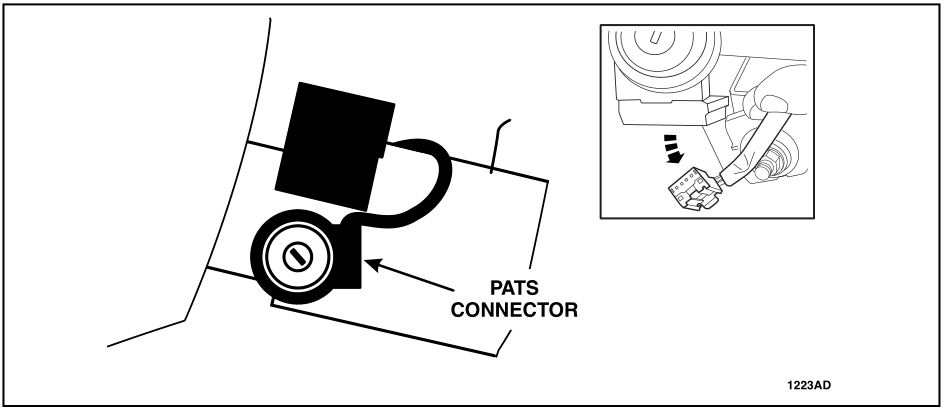

- If equipped, disconnect the Passive Anti-Theft System (PATS) transceiver electrical Remove the harness pin-type retainer and position the harness aside. See Figure 7.

Figure 7

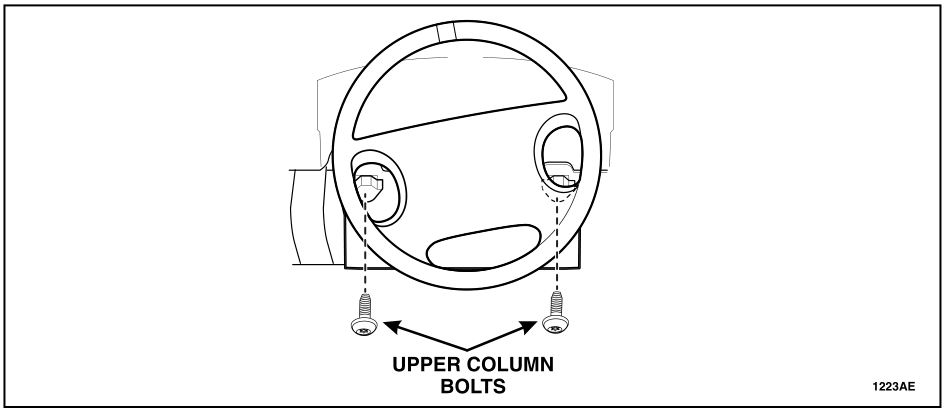

- Remove and discard the two upper column See Figure 8.

Figure 8

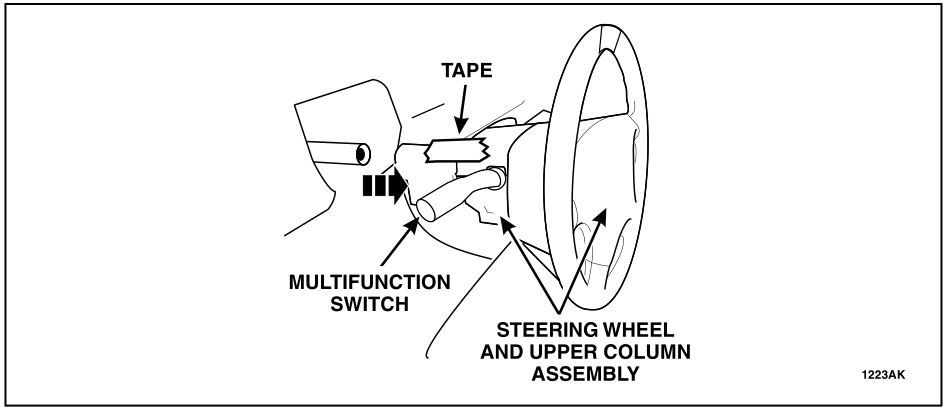

- Tape the wheel to the Multifunction Switch (MFS) to prevent rotation of the wheel. Pull out and remove the steering wheel and upper column assembly as a single unit. See Figure 9.

Figure 9

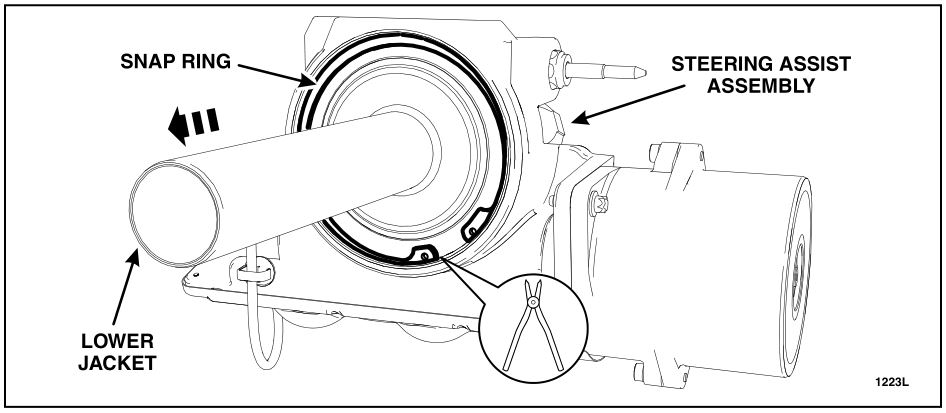

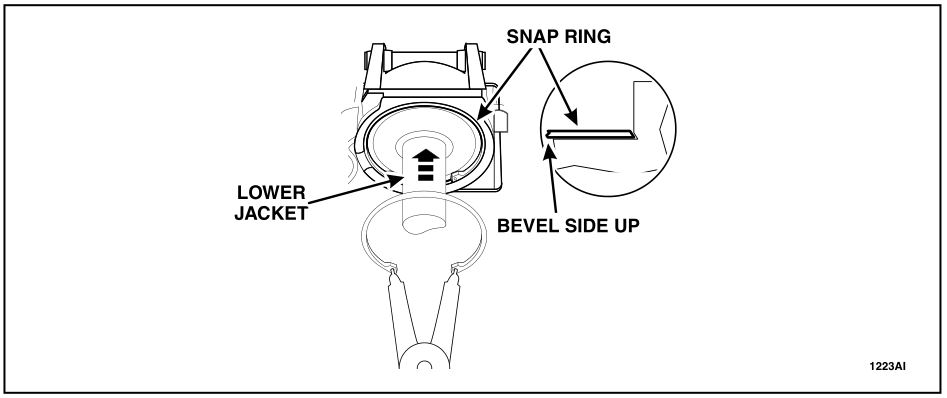

- Remove the snap ring using Rotor Clip RP-900 ratchet and grip ring pliers or Remove the lower jacket. See Figure 10.

Figure 10

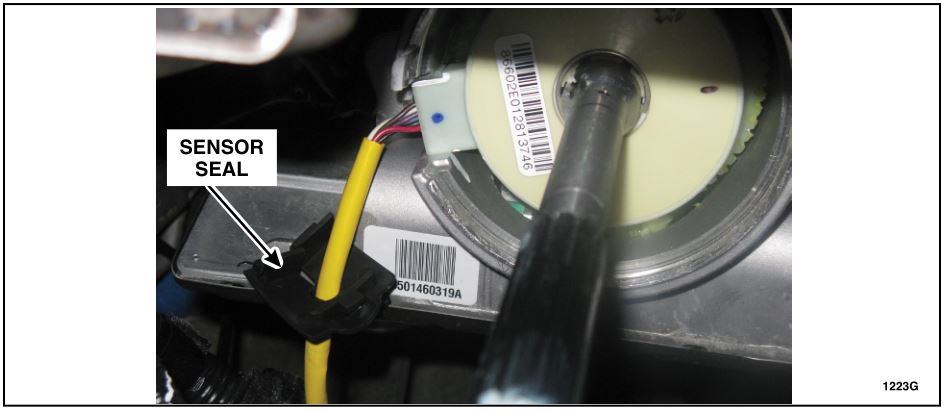

- Remove the sensor seal from the steering assist assembly. See Figure 11.

Figure 11

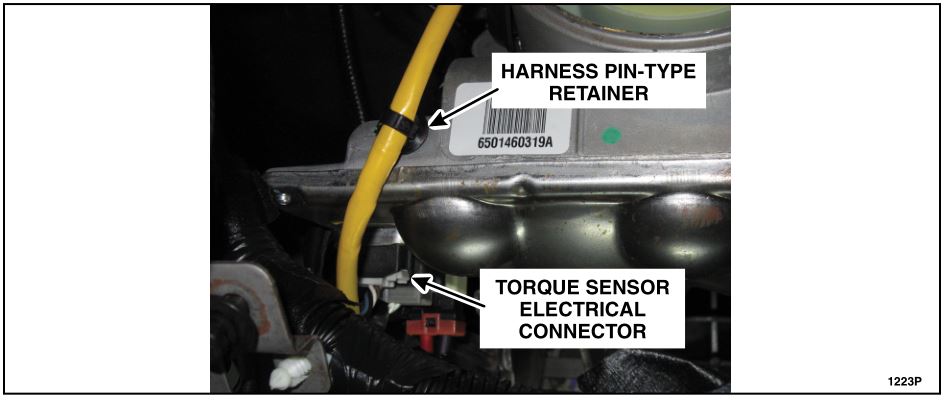

- Disconnect the torque sensor electrical connector and remove the harness pin-type See Figure 12.

Figure 12

- Raise the front of the vehicle high enough to remove the load off the front For additional information, refer to WSM Section 100-02.

To see a short video of the torque sensor installation, click “Here“.

IMPORTANT: Do not use pliers or locking pliers to turn the steering shaft or damage will occur. Two people are required to properly align the torque sensor.

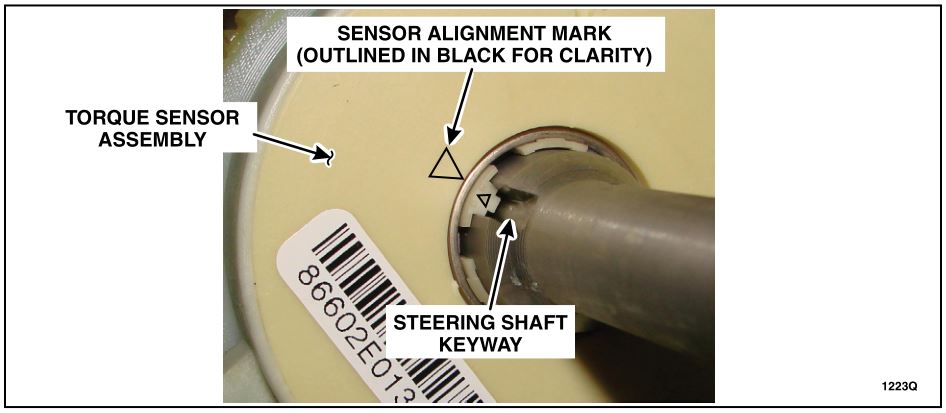

- Before removing the old torque sensor assembly, verify the steering shaft keyway is aligned with the sensor alignment mark. This will ensure that the steering input shaft is in the correct position for installation of the sensor alignment tool. (If necessary, have an assistant bump the front tires left or right until the sensor is perfectly aligned.) See Figure 13.

Figure 13

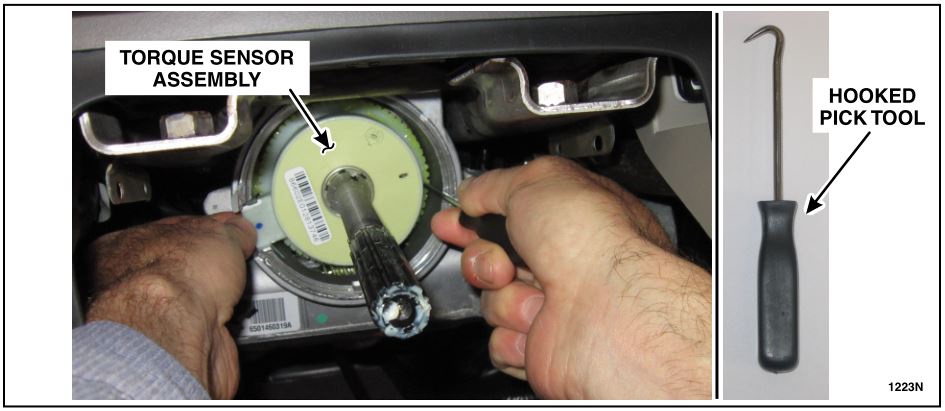

- Prying gently from the back, remove the torque sensor assembly. Remove the sensor by gently pulling up on the sensor wires while using a hooked pick tool to lift the opposite side of the sensor. See Figure 14.

Figure 14

- Inspect the underside of the sensor for In case of breakage or damage, replace the steering column. For additional information, refer to WSM Section 211-04.

- Vacuum the surface of the gear face to remove any Thoroughly vacuum the worm gear. See Figure 15.

Figure 15

IMPORTANT: Up and down movement of the steering gear assembly in the vehicle will cause the steering shaft to rotate slightly. When you begin the next step, you MUST keep the steering gear assembly “locked” in the same position. Up and down movement of the steering gear during alignment and installation process will result in a misaligned torque sensor.

IMPORTANT: The following steps (22 through 28) are CRITICAL for the proper installation of the torque sensor assembly.

NOTICE: The new torque sensor will come with a locking pin that ensures the steering angle sensor and the steering torque sensor are “locked” in the proper position. DO NOT remove this pin until the sensor assembly is completely installed.

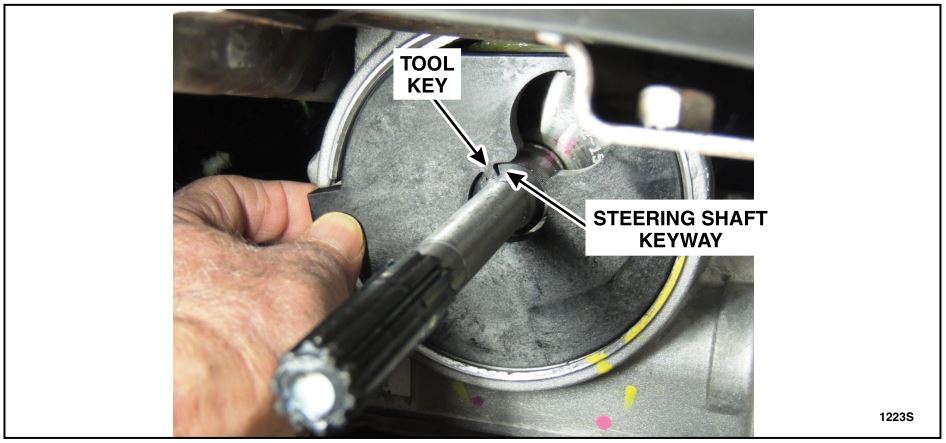

NOTE: Do not force tool into place, the tool must feel loose when in proper position.

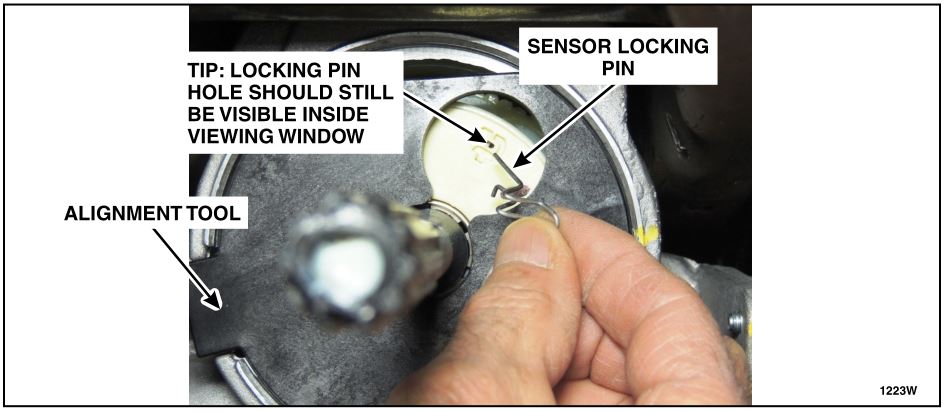

- Install the alignment tool. During installation of the tool, the tool key on the alignment tool should slide easily into the steering shaft key way. If there is any binding, have an assistant bump the tires slightly to the right or left again until the alignment tool falls into place. See Figure 16.

Figure 16

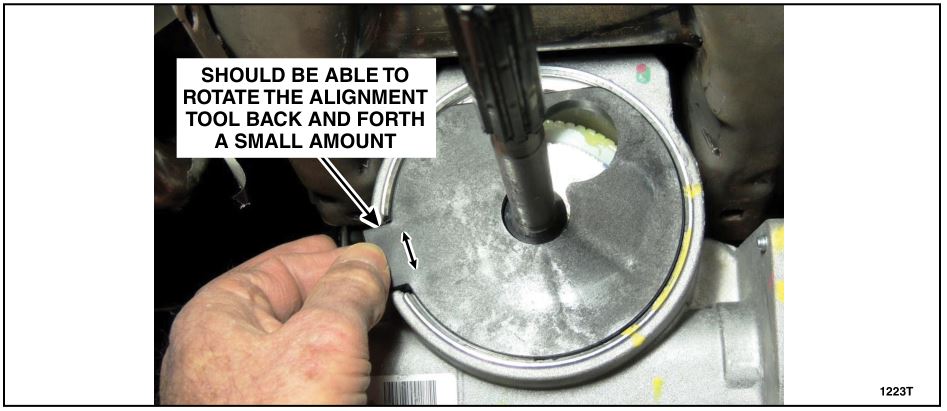

- While the alignment tool is in place, attempt to rotate the tool in the clockwise and counter-clockwise direction.

- If the alignment tool can freely rotate slightly in the clockwise and counter-clockwise direction, the tool is properly aligned. Proceed to Step 24. See Figure 17.

- If the alignment tool cannot freely rotate, the steering shaft is not Have an assistant bump the tires slightly until the alignment tool can be rotated slightly.

NOTE: The alignment tool should not feel stiff while rotating. If it does, the steering shaft is not aligned.

Figure 17

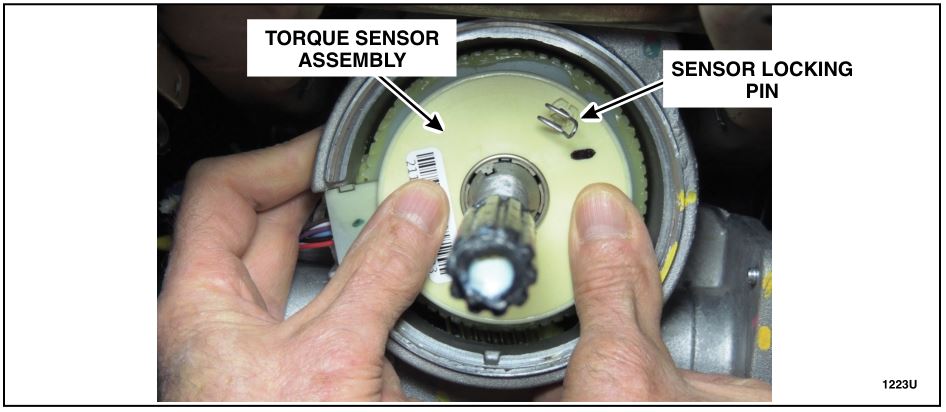

- After the steering shaft is perfectly aligned with the spline on the alignment tool, remove the alignment tool and carefully install the torque sensor assembly with the locking pin still in When seating the torque sensor assembly, apply gentle but even force on both sides of the sensor (DO NOT REMOVE THE LOCKING PIN YET). See Figure 18.

Figure 18

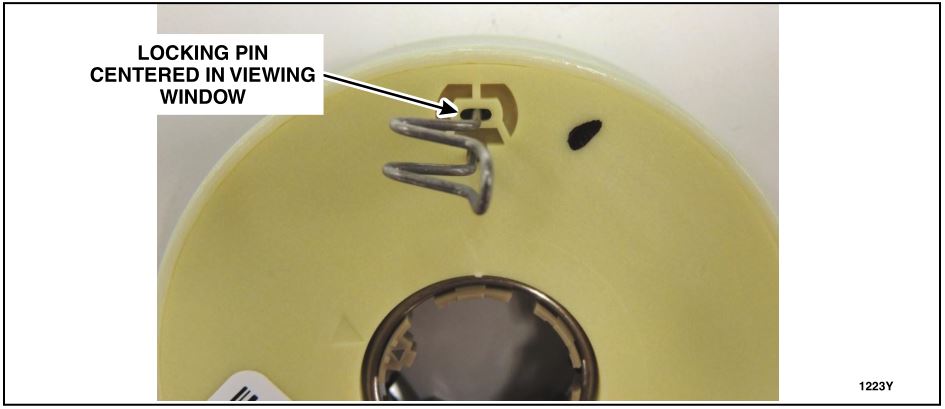

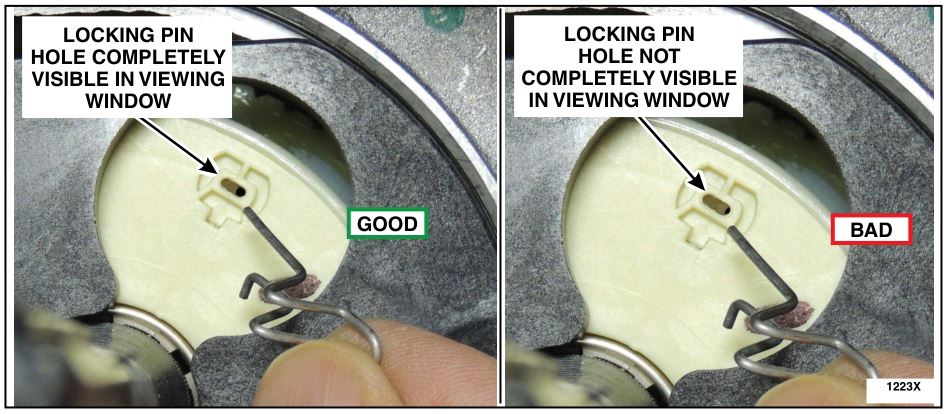

- Ensure the locking pin is not shifted to one side of the sensor viewing The optimal position for the locking pin is centered in the viewing window. See Figure 19.

Figure 19

- Fully Seating the Torque Sensor Assembly:

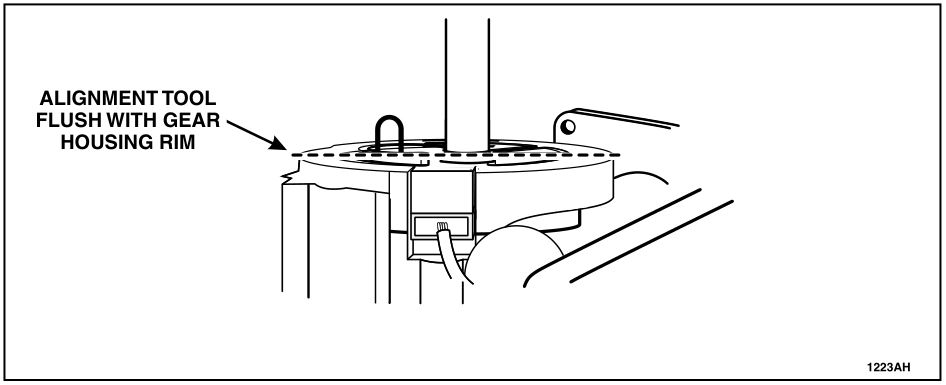

NOTICE: DO NOT push the torque sensor assembly past flush with the gear housing rim or damage to the sensor will occur.

Use the alignment tool to verify the torque sensor assembly is seated properly. The top of the alignment tool should be flush with gear housing rim. See Figure 20.

Figure 20

NOTICE: Do not drop the locking pin into the steering gear housing or damage may occur.

- While the alignment tool is still in place, remove the locking pin, then remove the alignment tool. See Figure 21.

Figure 21

TIP: When the locking pin is removed, the locking pin hole should still be visible inside the sensor viewing window. If the sensor was not properly aligned during installation, the locking pin hole will move out of view when the locking pin is removed.

- Check locking pin hole location.

- If the locking pin hole is completely visible (Figure 22a), the sensor is installed Proceed to Step 29.

- If the locking pin is not completely visible (Figure 22b), remove and discard the torque Obtain a new torque sensor and repeat Steps 22 through 28. See Figure 22a and 22b.

Figure 22a Figure 22b

- Connect the torque sensor electrical connector and install the harness pin-type See Figure 12.

- Reinstall the sensor seal onto the steering assist See Figure 11.

- Install the lower jacket and the original snap ring bevel side See Figure 23.

Figure 23

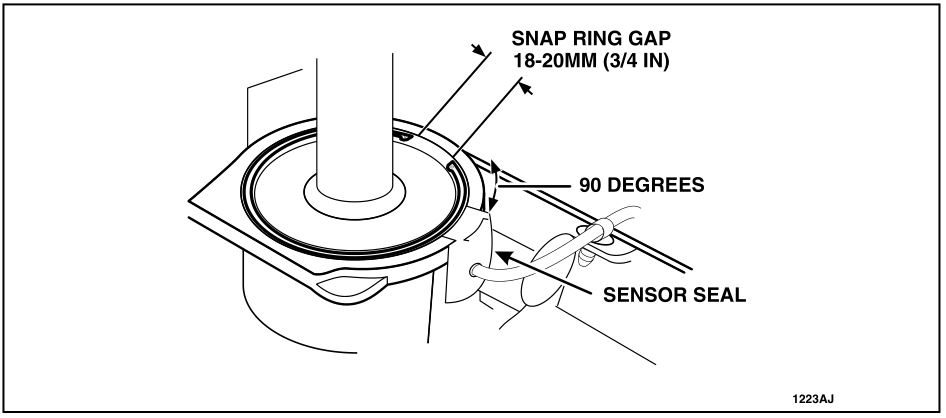

- Ensure snap ring gap is positioned 90 degrees from sensor seal. Measure the gap between snap ring Gap must be 18 – 20mm (3/4 in) to ensure snap ring is seated correctly. See Figure 24.

Figure 24

NOTE: The steering wheel and upper steering column assembly should slide on easily. Significant resistance means the upper column assembly is not properly aligned. If necessary, rotate the upper column assembly for proper alignment. All rotating parts must be properly aligned during assembly. Position tolerance ± 5 degrees.

- Install the steering wheel and upper column assembly and remove the Rotate the upper column assembly as necessary to align with block tooth on shaft.

- Install two (2) new upper column See Figure 8.

- Tighten bolts to 28 Nm (21 lb-ft).

- If equipped, connect the PATS transceiver electrical Reposition the harness and install the pin-type retainer. See Figure 7.

- Connect the three connectors on the left side of the column. Install the two harness pin-type See Figure 6.

- Install the lower column shroud and tighten the three machine See Figure 5.

- Install the upper column shroud. See Figure 4.

- Install the four bolts and the steering column opening panel. See Figure 3.

- Tighten to 8 Nm (71 lb-in).

- Install the steering column opening trim. See Figure 1.

- Connect the 12V For additional information, refer to WSM Section 414-01.

- Hybrid vehicles: Repower the high-voltage traction For additional information, refer to WSM Section 414-03.

- Lower the vehicle and start the With the engine running and a properly installed sensor, the steering wheel should stay centered. If the torque sensor is NOT installed properly (i.e. not centered during installation), the steering wheel will move all the way to the right or left. The torque sensor only needs to be off center a small amount to cause this type of problem. During normal operation, the torque sensor only moves a maximum -5 degree to +5 degrees.

- Perform Steering Wheel Position Sensor For additional information, refer to WSM Section 211-00.

SEOCONTENT-START**************************************************************************************************************Ford Motor Company Ford

Motor Company Ford Customer Service Division P.O. Box 1904 Dearborn, Michigan 48121 August 2015 2010 Mariner Vehicle ID#: * * * IMPORT ANT SAFETY RECALL REMINDER * * * (RECORDATOR/0 IMPORTANTE PROGRAMA DE SEGUR/DAD) According to our records, your 2010 Mariner has not had necessary safety recall repairs made. We urge you to have the free repair performed at your local dealership as soon as possible. KEY INFORMATION • Your vehicle is involved in an important safety recall • Your safety is important to us. Schedule an appointment to have service procedure completed • This procedure will be performed free of charge • Si necesita ayuda o tiene alguna pregunta, por favor flame al Centro de Relaci6n con Clientes al 1-866-436-7332 y presione 2 para Espanol Recall Number 14S05 – Electric Power Steering and Description: What is the Issue? What Are We Asking You To Do? Service Assistance: On your vehicle, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor. An unexpected loss of steering assist while driving would require higher steering effort at lower vehicle speeds, which may increase the risk of accident. Please contact your dealer to schedule an appointment to have this important service procedure completed. If you do not already have a servicing dealer, you can access www.Fordowner.com for dealer addresses, maps and driving instructions. The vehicle owner is responsible for having this service action performed. Ford

Customer Service Division P.O. Box 1904 Dearborn, Michigan 48121 August 2015 2010 Mariner Vehicle ID#: * * * IMPORT ANT SAFETY RECALL REMINDER * * * (RECORDATOR/0 IMPORTANTE PROGRAMA DE SEGUR/DAD) According to our records, your 2010 Mariner has not had necessary safety recall repairs made. We urge you to have the free repair performed at your local dealership as soon as possible. KEY INFORMATION • Your vehicle is involved in an important safety recall • Your safety is important to us. Schedule an appointment to have service procedure completed • This procedure will be performed free of charge • Si necesita ayuda o tiene alguna pregunta, por favor flame al Centro de Relaci6n con Clientes al 1-866-436-7332 y presione 2 para Espanol Recall Number 14S05 – Electric Power Steering and Description: What is the Issue? What Are We Asking You To Do? Service Assistance: On your vehicle, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor. An unexpected loss of steering assist while driving would require higher steering effort at lower vehicle speeds, which may increase the risk of accident. Please contact your dealer to schedule an appointment to have this important service procedure completed. If you do not already have a servicing dealer, you can access www.Fordowner.com for dealer addresses, maps and driving instructions. The vehicle owner is responsible for having this service action performed. Ford Motor Company reserves the right to deny coverage for any vehicle damage that may result from failure to have this recall performed on a timely basis. Therefore, please have this recall performed as soon as possible. If you have additional questions, please contact the Ford

Motor Company reserves the right to deny coverage for any vehicle damage that may result from failure to have this recall performed on a timely basis. Therefore, please have this recall performed as soon as possible. If you have additional questions, please contact the Ford Motor Company Customer Relationship Center at 1-866-436-7332 and one of our representatives will be happy to assist you. For the hearing impaired call 1-800-232-5952 (TDD). Office Hours are Monday through Friday: 8:00AM – 5:00PM (Your Local Time). If you wish to contact us through the Internet, our address is: www.Fordowner.com. If your authorized dealer has recently completed this recall repair, please disregard this reminder. We apologize for any inconvenience this may cause and want to assure you that, with your assistance, we will correct this condition. Our commitment, together with your dealer, is to provide you with the highest level of service and support. Thank you for your attention to this important matter. Ford

Motor Company Customer Relationship Center at 1-866-436-7332 and one of our representatives will be happy to assist you. For the hearing impaired call 1-800-232-5952 (TDD). Office Hours are Monday through Friday: 8:00AM – 5:00PM (Your Local Time). If you wish to contact us through the Internet, our address is: www.Fordowner.com. If your authorized dealer has recently completed this recall repair, please disregard this reminder. We apologize for any inconvenience this may cause and want to assure you that, with your assistance, we will correct this condition. Our commitment, together with your dealer, is to provide you with the highest level of service and support. Thank you for your attention to this important matter. Ford Customer Service Division **************************************************************************************************************

Customer Service Division **************************************************************************************************************

Ford Motor Company Ford

Motor Company Ford Customer Service Division P.O. Box 1904 Dearborn, Michigan 48121-1904 August 2017 * * * IMPORTANT SAFETY RECALL REMINDER** * (RECORDATOR/0 IMPORTANTE PROGRAMA DE SEGUR/DAD) According to our records, your 2011 Escape has not had necessary safety recall repairs made. We urge you to have the free repair performed at your local dealership as soon as possible. KEY INFORMATION • Your vehicle is involved in an important safety recall • Your safety is important to us. Schedule an appointment to have service procedure completed • This procedure will be performed free of charge • Si necesita ayuda o tiene alguna pregunta, por favor /lame al Centro de Relaci6n con Clientes al 1-866-436-7332 y presione 2 para Espanol Recall Number 14S05 – Electric Power Steering and Description: What is the Issue? What Are We Asking You To Do? Service Assistance: On your vehicle, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor An unexpected loss of steering assist while driving would require higher steering effort at lower vehicle speeds, which may increase the risk of accident. Please contact your dealer to schedule an appointment to have this important service procedure completed. If you do not already have a servicing dealer, you can access www.Fordowner.com for dealer addresses, maps and driving instructions. The vehicle owner is responsible for having this service action performed. Ford

Customer Service Division P.O. Box 1904 Dearborn, Michigan 48121-1904 August 2017 * * * IMPORTANT SAFETY RECALL REMINDER** * (RECORDATOR/0 IMPORTANTE PROGRAMA DE SEGUR/DAD) According to our records, your 2011 Escape has not had necessary safety recall repairs made. We urge you to have the free repair performed at your local dealership as soon as possible. KEY INFORMATION • Your vehicle is involved in an important safety recall • Your safety is important to us. Schedule an appointment to have service procedure completed • This procedure will be performed free of charge • Si necesita ayuda o tiene alguna pregunta, por favor /lame al Centro de Relaci6n con Clientes al 1-866-436-7332 y presione 2 para Espanol Recall Number 14S05 – Electric Power Steering and Description: What is the Issue? What Are We Asking You To Do? Service Assistance: On your vehicle, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor An unexpected loss of steering assist while driving would require higher steering effort at lower vehicle speeds, which may increase the risk of accident. Please contact your dealer to schedule an appointment to have this important service procedure completed. If you do not already have a servicing dealer, you can access www.Fordowner.com for dealer addresses, maps and driving instructions. The vehicle owner is responsible for having this service action performed. Ford Motor Company reserves the right to deny coverage for any vehicle damage that may result from failure to have this recall performed on a timely basis. Therefore, please have this recall performed as soon as possible. If you have additional questions, please contact the Ford

Motor Company reserves the right to deny coverage for any vehicle damage that may result from failure to have this recall performed on a timely basis. Therefore, please have this recall performed as soon as possible. If you have additional questions, please contact the Ford Motor Company Customer Relationship Center at 1-866-436-7332 and one of our representatives will be happy to assist you. For the hearing impaired call 1-800-232-5952 (TDD). Office Hours are Monday through Friday: 8:00AM – 5:00PM (Your Local Time). If you wish to contact us through the Internet, our address is: www.Fordowner.com. ff your authorized dealer has recently completed this recall repair, please disregard this reminder. We apologize for any inconvenience this may cause and want to assure you that, with your assistance, we will correct this condition. Our commitment, together with your dealer, is to provi,de you with th’e highest level of service and support. Thank you for your attention to this important matter. Ford

Motor Company Customer Relationship Center at 1-866-436-7332 and one of our representatives will be happy to assist you. For the hearing impaired call 1-800-232-5952 (TDD). Office Hours are Monday through Friday: 8:00AM – 5:00PM (Your Local Time). If you wish to contact us through the Internet, our address is: www.Fordowner.com. ff your authorized dealer has recently completed this recall repair, please disregard this reminder. We apologize for any inconvenience this may cause and want to assure you that, with your assistance, we will correct this condition. Our commitment, together with your dealer, is to provi,de you with th’e highest level of service and support. Thank you for your attention to this important matter. Ford Customer Service Division **************************************************************************************************************

Customer Service Division **************************************************************************************************************

Ford Motor Company Ford

Motor Company Ford Customer Service Division p, 0, Box 1904 Dearborn, Michigan 48121 R. FILE 330 TOWN CENTER DR STE 500 DEARBORN, MI 48126-2796 July 2014 * * * IMPORTANT SAFETY RECALL * * * (PROGRAMA DE SEGUR/DAD /MPORTANTE) Safety Recall Notice 14505 J NHT5A RecaU14V-284 Aviso de Revision de 5eguridad 14505 This notice applies to your vehicle: 2011 Escape Your Vehicle Identification Number: This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act. Ford

Customer Service Division p, 0, Box 1904 Dearborn, Michigan 48121 R. FILE 330 TOWN CENTER DR STE 500 DEARBORN, MI 48126-2796 July 2014 * * * IMPORTANT SAFETY RECALL * * * (PROGRAMA DE SEGUR/DAD /MPORTANTE) Safety Recall Notice 14505 J NHT5A RecaU14V-284 Aviso de Revision de 5eguridad 14505 This notice applies to your vehicle: 2011 Escape Your Vehicle Identification Number: This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act. Ford Motor Company has decided that a defect which relates to motor vehicle safety exists in your vehicle, with the Vehicle Identification Number shown above, We apologize for this situation and want to assure you that, with your assistance, we will correct this condition. Our commitment, together with your dealer, is to provide you with the highest level of service and support. What is the issue? What will Ford

Motor Company has decided that a defect which relates to motor vehicle safety exists in your vehicle, with the Vehicle Identification Number shown above, We apologize for this situation and want to assure you that, with your assistance, we will correct this condition. Our commitment, together with your dealer, is to provide you with the highest level of service and support. What is the issue? What will Ford and your dealer do? How long will it take? What should you do? On your vehicle, the power steering system may revert to manual steering mode dlJ’3 to an Electric Power Steering system fault re!ated to the torque sensor. An unexpected loss of steering assist while driving would require higher steering effort at lower vehicle speeds, which may increase the risk of accident. Ford

and your dealer do? How long will it take? What should you do? On your vehicle, the power steering system may revert to manual steering mode dlJ’3 to an Electric Power Steering system fault re!ated to the torque sensor. An unexpected loss of steering assist while driving would require higher steering effort at lower vehicle speeds, which may increase the risk of accident. Ford Motor Company has authorized your dealer to update the appropriate modules to prevent loss of steering assist while driving due to a torque sensor fault. In addition, the update provides increased driver awareness by sounding a chime and displaying the wrench light or warning in the message center when a fault is detected, Alternatively, the dealer may need to replace the torque sensor or the steering column. This service will be performed free of charge (parts and labor). The time needed for this repair is less than one-half day, However, due to service scheduling requirements, your dealer may need your vehicle for a longer period of time. Please call your dealer without delay and request a service date for Recall 14S05. Provide the dealer with the Vehicle Identification Number (VIN) of your vehicle. The VIN is printed near your name at the beginning of this letter. If you do not already have a servicing dealer, you can access www.Fordowner.com for dealer addresses, maps, and driving instructions. What should you do? (Continued) Have you previously paid for this repair? What if you no longer own this vehicle? Ford

Motor Company has authorized your dealer to update the appropriate modules to prevent loss of steering assist while driving due to a torque sensor fault. In addition, the update provides increased driver awareness by sounding a chime and displaying the wrench light or warning in the message center when a fault is detected, Alternatively, the dealer may need to replace the torque sensor or the steering column. This service will be performed free of charge (parts and labor). The time needed for this repair is less than one-half day, However, due to service scheduling requirements, your dealer may need your vehicle for a longer period of time. Please call your dealer without delay and request a service date for Recall 14S05. Provide the dealer with the Vehicle Identification Number (VIN) of your vehicle. The VIN is printed near your name at the beginning of this letter. If you do not already have a servicing dealer, you can access www.Fordowner.com for dealer addresses, maps, and driving instructions. What should you do? (Continued) Have you previously paid for this repair? What if you no longer own this vehicle? Ford Motor Company wants you to have this safety recall completed on your vehicle. The vehicle owner is responsible for making arrangements to have the work completed. Please note: Federal law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days. If you have previously paid for a repair that addresses the issue described in this letter, you still need to have this recall performed to ensure the correct parts and procedures were used. You may be eligible for a refund of previously paid repairs. Refunds will only be provided for service related to steering column or torque sensor replacement for loss of power steering assist. To verify eligibility and expedite reimbursement, give your paid original receipt to your dealer. Refund requests may also be sent directly to Ford Motor Company. To request your refund from Ford, send the refund request with all required documentation, including your original repair receipt (no photocopies), to Ford Motor Company at P.O. Box 6251, Dearborn, Michigail4812~-625~. Refund requests mailed tc th:s address may take up to 60 days to process. Your original receipt will be returned to you. Detailed information regarding eligibility for Ford’s reimbursement program and documentation requirements may be obtained by contacting the Ford Customer Relationship Center at 1-866-436-7332. If you no longer own this vehicle, and have an address for the current owner, please forward this letter to the new owner. You received this notice because government regulations require that notification be sent to the last known owner of record. Our records are based primarily on state registration and title data, which indicate that you are the current owner. If you have difficulties getting your vehicle repaired promptly and without charge, please contact your dealership’s Service Manager for assistance. RETAIL OWNERS: If you still have concerns, please contact the Ford Motor Company Customer Relationship Center at 1-866-436-7332 and one of our representatives will be happy to assist you. For the hearing impaired call 1-800-232-5952 (TOO). Representatives are available Monday through Friday: 8:00AM – 8:00PM (Eastern Time). If you wish to contact us through the Internet, our address is: www.Fordowner.com. Para esistencie en Espano/:’ Si necesita ayuda 0 tiene a/guna pregunta, por favor /lame a/ Centro de Re/aci6n con C/ientes a/1-866-436-7332 y presione 2 para Espano/. FLEET OWNERS: If you still have concerns, please contact the Fleet Customer Information Center at 1-800-34-FLEET, Option #3 and one of our representatives will be happy to assist you. Representatives are available Monday through Friday: 8:00AM – 8:00PM (Eastern Time). Or you may contact us through the Internet at www.fleetJord.com. If you are still having difficulty getting your vehicle repaired in a reasonable time or without charge, you may write the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave. S.E., Washington, D.C. 20590 or call the toll free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153) or go to www.safercar.gov. Reference NHTSA Safety Recall 14V-284. Thank you for your attention to this important matter. Can we assist you further? 2012 24774/123623/0586 Ford Customer Service Division **************************************************************************************************************

Motor Company wants you to have this safety recall completed on your vehicle. The vehicle owner is responsible for making arrangements to have the work completed. Please note: Federal law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days. If you have previously paid for a repair that addresses the issue described in this letter, you still need to have this recall performed to ensure the correct parts and procedures were used. You may be eligible for a refund of previously paid repairs. Refunds will only be provided for service related to steering column or torque sensor replacement for loss of power steering assist. To verify eligibility and expedite reimbursement, give your paid original receipt to your dealer. Refund requests may also be sent directly to Ford Motor Company. To request your refund from Ford, send the refund request with all required documentation, including your original repair receipt (no photocopies), to Ford Motor Company at P.O. Box 6251, Dearborn, Michigail4812~-625~. Refund requests mailed tc th:s address may take up to 60 days to process. Your original receipt will be returned to you. Detailed information regarding eligibility for Ford’s reimbursement program and documentation requirements may be obtained by contacting the Ford Customer Relationship Center at 1-866-436-7332. If you no longer own this vehicle, and have an address for the current owner, please forward this letter to the new owner. You received this notice because government regulations require that notification be sent to the last known owner of record. Our records are based primarily on state registration and title data, which indicate that you are the current owner. If you have difficulties getting your vehicle repaired promptly and without charge, please contact your dealership’s Service Manager for assistance. RETAIL OWNERS: If you still have concerns, please contact the Ford Motor Company Customer Relationship Center at 1-866-436-7332 and one of our representatives will be happy to assist you. For the hearing impaired call 1-800-232-5952 (TOO). Representatives are available Monday through Friday: 8:00AM – 8:00PM (Eastern Time). If you wish to contact us through the Internet, our address is: www.Fordowner.com. Para esistencie en Espano/:’ Si necesita ayuda 0 tiene a/guna pregunta, por favor /lame a/ Centro de Re/aci6n con C/ientes a/1-866-436-7332 y presione 2 para Espano/. FLEET OWNERS: If you still have concerns, please contact the Fleet Customer Information Center at 1-800-34-FLEET, Option #3 and one of our representatives will be happy to assist you. Representatives are available Monday through Friday: 8:00AM – 8:00PM (Eastern Time). Or you may contact us through the Internet at www.fleetJord.com. If you are still having difficulty getting your vehicle repaired in a reasonable time or without charge, you may write the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave. S.E., Washington, D.C. 20590 or call the toll free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153) or go to www.safercar.gov. Reference NHTSA Safety Recall 14V-284. Thank you for your attention to this important matter. Can we assist you further? 2012 24774/123623/0586 Ford Customer Service Division **************************************************************************************************************

Michael A. Berardi Director Service Engineering Operations Ford Customer Service Division Ford Motor Company P. O. Box 1904 Dearborn, Michigan 48121 May 29,2014 TO: All U.S. Ford and Lincoln Dealers SUBJECT: Advance Notice – Safety Recall 14S05 Certain 2008-2011 Model Year Escape and Mariner Vehicles Electric Power Steering AFFECTED VEHICLES Certain 2008-2011 model year Escape and Mariner vehicles built at the Kansas City Assembly Plant from Job #1 2008 through September 11, 2010. Affected vehicles are identified in OASIS. In addition, for a list of vehicles assigned to your dealership, visit https://web.fsavinlists.dealerconnection.com. This information will be available on May 29, 2014. REASON FOR THIS SAFETY RECALL In some of the affected vehicles, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor. In manual steering mode there is still a mechanical linkage between the steering wheel and the road wheel, allowing steering control to be maintained. If this condition should occur, the steering effort may be greater, especially at low speeds, which may increase the risk of accident. SERVICE ACTION It is anticipated that a complete Dealer Bulletin will be provided to dealers by the week of June 16, 2014, once the software to perform the repair is available. NOTE: The software to perform the repair is currently not available to support Safety Recall 14S05, but is expected to be released in mid-June. In the interim period, if an affected vehicle arrives at your dealership with a customer complaint of loss of steering assist, please contact the Special Service Support Center for direction. CUSTOMER NOTIFICATION Owners of record will be notified via first-class mail after repair instructions and parts ordering information have been provided to dealers. QUESTIONS? Special Service Support Center (Dealer Assistance Only) 1-800-325-5621 Sincerely, Michael A Berardi **************************************************************************************************************

Dealers SUBJECT: Advance Notice – Safety Recall 14S05 Certain 2008-2011 Model Year Escape and Mariner Vehicles Electric Power Steering AFFECTED VEHICLES Certain 2008-2011 model year Escape and Mariner vehicles built at the Kansas City Assembly Plant from Job #1 2008 through September 11, 2010. Affected vehicles are identified in OASIS. In addition, for a list of vehicles assigned to your dealership, visit https://web.fsavinlists.dealerconnection.com. This information will be available on May 29, 2014. REASON FOR THIS SAFETY RECALL In some of the affected vehicles, the power steering system may revert to manual steering mode due to an Electric Power Steering system fault related to the torque sensor. In manual steering mode there is still a mechanical linkage between the steering wheel and the road wheel, allowing steering control to be maintained. If this condition should occur, the steering effort may be greater, especially at low speeds, which may increase the risk of accident. SERVICE ACTION It is anticipated that a complete Dealer Bulletin will be provided to dealers by the week of June 16, 2014, once the software to perform the repair is available. NOTE: The software to perform the repair is currently not available to support Safety Recall 14S05, but is expected to be released in mid-June. In the interim period, if an affected vehicle arrives at your dealership with a customer complaint of loss of steering assist, please contact the Special Service Support Center for direction. CUSTOMER NOTIFICATION Owners of record will be notified via first-class mail after repair instructions and parts ordering information have been provided to dealers. QUESTIONS? Special Service Support Center (Dealer Assistance Only) 1-800-325-5621 Sincerely, Michael A Berardi **************************************************************************************************************