| “This site contains affiliate links for which OEMDTC may be compensated” |

February 7, 2017

TO: All U.S. Ford and Lincoln

and Lincoln Dealers

Dealers

SUBJECT: NEW VEHICLE DEMONSTRATION / DELIVERY HOLD

Update Prior to Sale 16U32 – Supplement #2

Certain 2017 Model Year F-250 to F-750 F-Super Duty Vehicles Equipped with a 6.7L Diesel Engine

Engine Oil Pressure Inspection

REF: NEW VEHICLE DEMONSTRATION / DELIVERY HOLD

Update Prior to Sale 16U32

Dated December 30, 2016

New! REASON FOR THIS SUPPLEMENT

A review of service part requests and IDS recordings indicate that some dealers are incorrectly identifying vehicles as having a lack of engine oil pressure (fail condition). Dealers are requested to repeat Phase Two of the technical instructions on new unsold vehicles currently being held for parts. Vehicles that pass inspection may be demonstrated and delivered immediately.

NOTE: It is not necessary to repeat Phase One on vehicles that have already been tested in order to repeat Phase Two.

Service Action and Technical Instructions Update: For vehicles that fail inspection conducted on and after February 7, 2017, dealers are to:

- Submit a screen shot of the IDS recording demonstrating the fail condition to the SSSC for further repair direction and to order parts.

- Send the IDS session file to Ford

.

.

Labor Allowances: Labor allowance 16U32D has been added to provide additional time for screen shot and session file submissions. Claims with labor operation code 16U32C with a repair date of February 11, 2017 and later will no longer be accepted.

PROGRAM TERMS

This program will be in effect through December 31, 2017, for new unsold vehicles only, and is not applicable to sold vehicles.

AFFECTED VEHICLES

| Vehicle | Model Year | Assembly Plant | Build Dates |

| F-250 – F-550 | 2017 | Kentucky | February 3, 2016 through November 30, 2016 |

| F-350 – F-550 | Ohio | May 4, 2016 through December 6, 2016 | |

| F-650 – F-750 | April 18, 2016 through December 6, 2016 |

Affected vehicles are identified in OASIS and FSA VIN Lists.

REASON FOR THIS PROGRAM

In some of the affected vehicles, the engine may lack oil pressure at start up after a cold soak due to concerns with the oil pump. This condition may lead to engine failure at very low mileage.

New! SERVICE ACTION

Before demonstrating or delivering any new in-stock vehicles involved in this program, dealers are to inspect for a lack of engine oil pressure and if necessary contact the SSSC for further repair direction following the technical instructions found in Attachment III.

A review of service part requests and IDS recordings indicate that some dealers are incorrectly identifying vehicles as having a lack of engine oil pressure (fail condition). Dealers are requested to repeat Phase Two of the technical instructions on new unsold vehicles currently being held for parts. Vehicles that pass inspection may be demonstrated and delivered immediately.

NOTE: It is not necessary to repeat Phase One on vehicles that have already been tested in order to repeat Phase Two.

NOTE: Less than 1% of the affected vehicles are expected to require a repair based on the inspection.

NOTE: To ensure a positive customer delivery experience, dealers are requested to immediately conduct this procedure on all affected new in-stock vehicles in your inventory. The inspection procedure is a two-phase operation with an 8 hour wait between phases. Please ensure that adequate time is allotted to perform this procedure prior to the demonstration or delivery of vehicles affected.

OWNER NOTIFICATION MAILING SCHEDULE

Owner letters will not be mailed for this program.

New! ATTACHMENTS

Attachment I: Administrative Information

Attachment II: Labor Allowances

Attachment III: Technical Information

QUESTIONS & ASSISTANCE

For questions and assistance, contact the Special Service Support Center (SSSC) via the SSSC Web Contact Site. The SSSC Web Contact Site can be accessed through the Professional Technician Society (PTS) website using the SSSC link listed at the bottom of the OASIS VIN report screen or listed under the SSSC tab.

Sincerely,

Michael A. Berardi

ATTACHMENT I

NEW VEHICLE DEMONSTRATION / DELIVERY HOLD

Update Prior to Sale 16U32 – Supplement #2

Certain 2017 Model Year F-250 to F-750 F-Super Duty Vehicles Equipped with a 6.7L Diesel Engine

Engine Oil Pressure Inspection

OASIS ACTIVATION

OASIS will be activated on December 30, 2016.

FSA VIN LISTS ACTIVATION

FSA VIN Lists will be available through https://web.fsavinlists.dealerconnection.com on December 30, 2016.

SOLD VEHICLES

Repair affected vehicles brought to your dealership that exhibit low oil pressure under the applicable Ford Bumper-to-Bumper warranty coverage period.

Bumper-to-Bumper warranty coverage period.

STOCK VEHICLES

Correct all affected units in your new vehicle inventory before delivery.

TITLE BRANDED / SALVAGED VEHICLES

Affected title branded and salvaged vehicles are eligible for this service action.

ADDITIONAL REPAIR (LABOR TIME AND/OR PARTS)

Additional repairs identified as necessary to complete the FSA should be managed as follows:

- For vehicles within new vehicle bumper-to-bumper warranty coverage, follow existing warranty and policy guidelines for related damage claims. No SSSC approval is required for these vehicles:

- Ford

vehicles – 3 years or 36,000 miles

vehicles – 3 years or 36,000 miles - F-650 / F-750 trucks – 2 years, regardless of miles driven

- Ford

OWNER REFUNDS

Refunds are not approved for this program.

RENTAL VEHICLES

The use of rental vehicles is not approved for this program.

New! CLAIMS PREPARATION AND SUBMISSION

NOTE: Prepare and enter claims using Direct Warranty Entry (DWE) or One Warranty Solution (OWS).

- DWE: If you enter claims in the ACESII Warranty screen, enter claims using DWE.

- Refer to ACESII Manual for claims preparation and submission information.

- Use code information shown below:

- Program Code (DWE) – 16U32

- Labor Operation – 16U32A or 16U32C (inspection dependent)

- Causal Component – 6019

- Condition Code – 42

- Customer Concern Code – E69

- OWS: Enter claims in Dealer Management Software (DMS). These instructions are only fordealers that have completed the launch to OWS and, as a result, are no longer able to reachACESII online.

- Refer to the OWS Manual for claims preparation and submission information.

- Use code information shown below:

- Claim Type 31 – Field Service Action

- Sub Code (OWS) – 16U32

- Labor Operation – 16U32A or 16U32C (inspection dependent)

- Additional labor and/or parts must be claimed as related damage on a separate repair line from the FSA.

- PROGRAM TERMS: This program will be in effect through December 31, 2017, for new unsold vehicles only, and is not applicable to sold vehicles.

- Provision for Locally Obtained Supplies: An allowance is provided for locally obtaining 2 gallons of diesel fuel and Metal Surface Prep Wipes (ZC-31-B). One container of Metal Surface Prep Wipes (ZC-31-B) can be used on approximately 25 vehicles (one wipe per vehicle required). These provisions are for the amount used for one vehicle repair. Submit on the same line as the repair.

- Program Code: 16U32

- Expense: OTHER

- Expense: Claim up to $18.00

ATTACHMENT II

NEW VEHICLE DEMONSTRATION / DELIVERY HOLD

Update Prior to Sale 16U32 – Supplement #2

Certain 2017 Model Year F-250 to F-750 F-Super Duty Vehicles Equipped with a 6.7L Diesel Engine

Engine Oil Pressure Inspection

New! LABOR ALLOWANCES

| Description | Labor Operation | Labor Time |

| Inspect Engine Oil Pressure – PASS (no service required) This labor operation closes the program | 16U32A | 0.4 Hours |

| Engine Front Cover Replacement – FAIL

Includes engine oil pressure inspection and time to submit IDS screen shot and session file | 16U32D | 17.0 Hours |

New! PARTS REQUIREMENTS / ORDERING INFORMATION

NOTE: Less than 1% of the affected vehicles are expected to require a repair based on the inspection.

SSSC Web Contact Site:

To place an order for the engine front cover, submit a VIN-specific Part Order contact via the SSSC Web Contact Site. The Part Order must include a file attachment containing a screen shot of the IDS recording demonstrating the fail condition. The file attachment must be 1MB or smaller. Refer to the technical instructions found in Attachment III for additional information.

| Part Number | Description | Order Quantity | Claim Quantity |

| HC3Z-6019-A | Engine Front Cover | 1 | 1 |

The DOR/COR number for this program is 51069.

Dealers will be notified via a DOES II communication if circumstances warrant a change in part supply strategy and when open ordering resumes.

Order the parts below through normal order processing channels:

| Part Number | Description | Order Quantity | Claim Quantity |

| HC3Z-8527-B | Transmission Oil Cooler Coolant Tube O-rings (1/package, 2 needed) | 2 | 2 |

| BC3Z-6379-B | Crankshaft Pulley Bolts (4/package, 4 needed) | 1 | 4 |

| BC3Z-6700-A | Front Crankshaft Seal | 1 | 1 |

| BC3Z-6310-A | Front Crankshaft Slinger | 1 | 1 |

W715618-S437 | Torque Converter Nut (4/package, 6 needed) | 2 | 6 |

| N808684-S101 | Steering Column Shaft Bolt | 1 | 1 |

| HC3Z-2A572-A | Vacuum Pump Gasket | 1 | 1 |

| W715106-S439 | Engine Mount Cross Through Bolt (4/package, 2 needed) | 1 | 2 |

| W718444-S439 | Engine Mount Bracket Bolt (4/package, 8 needed) | 2 | 8 |

PARTS REQUIREMENTS / ORDERING INFORMATION (Continued)

Order the parts below through normal order processing channels (Continued):

| Part Number | Description | Order Quantity | Claim Quantity |

| BC3Z-9439-C | Upper Intake Manifold Gasket (2/package, 2 needed) | 1 | 2 |

| BC3Z-9439-A | Upper Intake Manifold Gasket | 1 | 1 |

| BC3Z-9439-B | Upper Intake Manifold Gasket | 1 | 1 |

| W716088-S900 | Turbo Coolant Outlet Tube Bolt (2/package, 1 needed) | 1 | 1 |

| BC3Z-6587-A | Turbo Mounting Gasket | 1 | 1 |

| W714639-S439 | Turbo Mounting Bolt (1/package, 4 needed) | 4 | 4 |

| BC3Z-6N640-A | Exhaust Manifold to Turbo Inlet Pipe Gasket (2/package, 2 needed) | 1 | 2 |

| W711402-S900 | Exhaust Manifold to Turbo Inlet Pipe Nut (1/package, 6 needed) | 6 | 6 |

| BC3Z-8287-A | Turbo Inlet Pipe to Turbo Clamp (1/package, 2 needed) | 2 | 2 |

| FC3Z-8287-A | Turbo Outlet Pipe to Turbo Clamp | 1 | 1 |

W718005-S900 | Turbo Outlet Pipe to Exhaust Bolt (2/package, 2 needed) | 1 | 2 |

| W520112-S442 | Turbo Outlet Pipe Mount Nut (4/package, 2 needed) | 1 | 2 |

| W709771-S440 | Transmission Mount Nut (1/package, 2 needed) | 1 | 2 |

| DC3Z-6710-A | Upper Oil Pan to Block Gasket (2/package, 2 needed) | 1 | 2 |

| DC3Z-6710-B | Upper Oil Pan to Block Gasket | 1 | 1 |

| DC3Z-6L621-A | Upper Oil Pan to Oil Cooler Gasket | 1 | 1 |

| DC3Z-6L621-C | Upper Oil Pan to Oil Cooler Gasket | 1 | 1 |

| DC3Z-6L621-B | Upper Oil Pan to Oil Cooler Gasket | 1 | 1 |

| BC3Z-6840-A | Upper Oil Pan to Oil Filter Adapter Gasket | 1 | 1 |

| DS7Z-19B596-A | A/C Line O-ring (1/package, 2 needed) | 2 | 2 |

| BC3Z-6731-B | Oil Filter | 1 | 1 |

| XO-10W30-QSD | SAE 10W-30 Super Duty Diesel Motor Oil | 13 quarts | 13 quarts |

| VC-3-B | Orange Concentrated Antifreeze/Coolant | 1 | 1 |

| XT-10-QLVC | Mercon LV Automatic Transmission Fluid | 3 quarts | 3 quarts |

| TA-357 | High Performance Engine RTV Silicone | 1 | 1 |

PARTS REQUIREMENTS / ORDERING INFORMATION (Continued)

Order the parts below through normal order processing channels (Continued):

| Part Number | Description | Order Quantity | Claim Quantity |

| ZC-30-A | Silicone Gasket Remover | 1 | 1 |

| PM-4-A | Metal Brake Parts Cleaner | 1 | 1 |

| XL-5-A | Multi-Purpose Grease Spray | 1 | 1 |

TA-25-B | Threadlock Sealer (To be used for body bolts) | 1 | 1 |

| ZC-31-B | Metal Surface Prep Wipes (25/package, 1 needed) | 1 | Claim as Misc.

OTHER |

To guarantee the shortest delivery time, an emergency order for parts must be placed.

DEALER PRICE

For latest prices, refer to DOES II.

PARTS RETENTION AND RETURN

Follow the provisions of the Warranty and Policy Manual, Section 1 – WARRANTY PARTS RETENTION AND RETURN POLICIES.

EXCESS STOCK RETURN

Excess stock returned for credit must have been purchased from Ford Customer Service Division in accordance with Policy Procedure Bulletin 4000.

Customer Service Division in accordance with Policy Procedure Bulletin 4000.

ATTACHMENT III

CERTAIN 2017 MODEL YEAR F-250 TO F-750 F-SUPER DUTY VEHICLES EQUIPPED WITH A 6.7L DIESEL ENGINE — ENGINE OIL PRESSURE INSPECTION

OVERVIEW

In some of the affected vehicles, the engine may lack oil pressure at start up after a cold soak due to concerns with the oil pump. This condition may lead to engine failure at very low mileage. Before demonstrating or delivering any new in-stock vehicles involved in this program, dealers are to inspect for a lack of engine oil pressure and if necessary contact the SSSC for further repair direction following these technical instructions.

The minimum 30 minute engine RPM increase is needed to achieve 90C (194F) engine oil temperature to complete the engine oil pressure inspection.

A review of service part requests and IDS recordings indicate that some dealers are incorrectly identifying vehicles as having a lack of engine oil pressure (fail condition). Dealers are requested to repeat Phase Two of the technical instructions on new unsold vehicles currently being held for parts. Vehicles that pass inspection may be demonstrated and delivered immediately.

NOTE: It is not necessary to repeat Phase One on vehicles that have already been tested in order to repeat Phase Two.

NOTE: Less than 1% of the affected vehicles are expected to require engine front cover replacement based on this inspection.

NOTE: To ensure a positive customer delivery experience, dealers are requested to immediately conduct this procedure on all affected new in-stock vehicles in your inventory. The inspection procedure is a two-phase operation with an 8 hour wait between phases. Please ensure that adequate time is allotted to perform this procedure prior to the demonstration or delivery of vehicles affected.

SERVICE PROCEDURE

Phase One

NOTE: If the vehicle has been stored in ambient temperatures -18C (0F) or below, allow the vehicle to warm inside the shop before starting this procedure. Otherwise in extremely cold temperatures, the Integrated Diagnostic Software (IDS) Desired Idle Speed RPM (RPMDSD) control function will not increase the RPM to the level required in step 2. For in-shop repair efficiency, consider beginning the pre-soak procedure just prior to shop close.

NOTE: This procedure has two phases and both can be conducted outside the shop/service bay if the ambient temperature is above -18C (0F) at the start of the initial phase.

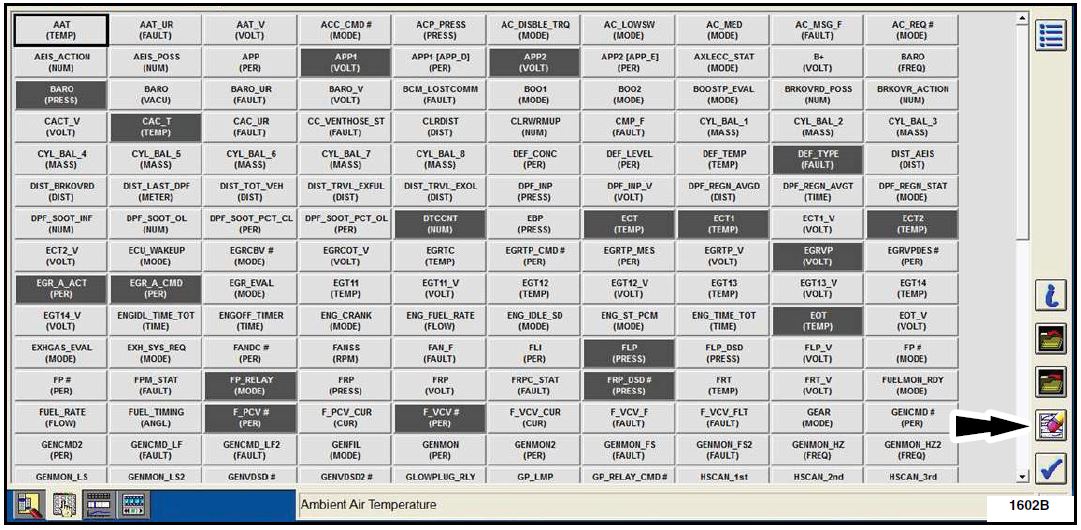

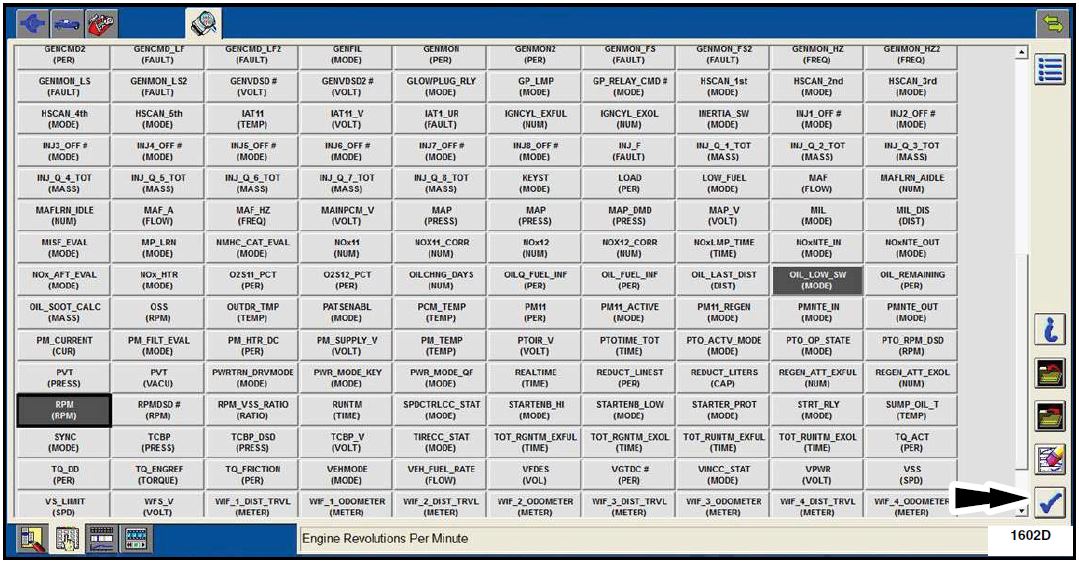

- Connect IDS and navigate to the RPMDSD Parameter Identification (PID). See Figures 1 and 2.

- A. Select Tool Box > Data Logger > Powertrain > Engine.

- B. Clear all pre-selected Parameter Identification (PID) boxes by pressing the clear button in the lower right corner of the screen. See Figure 1.

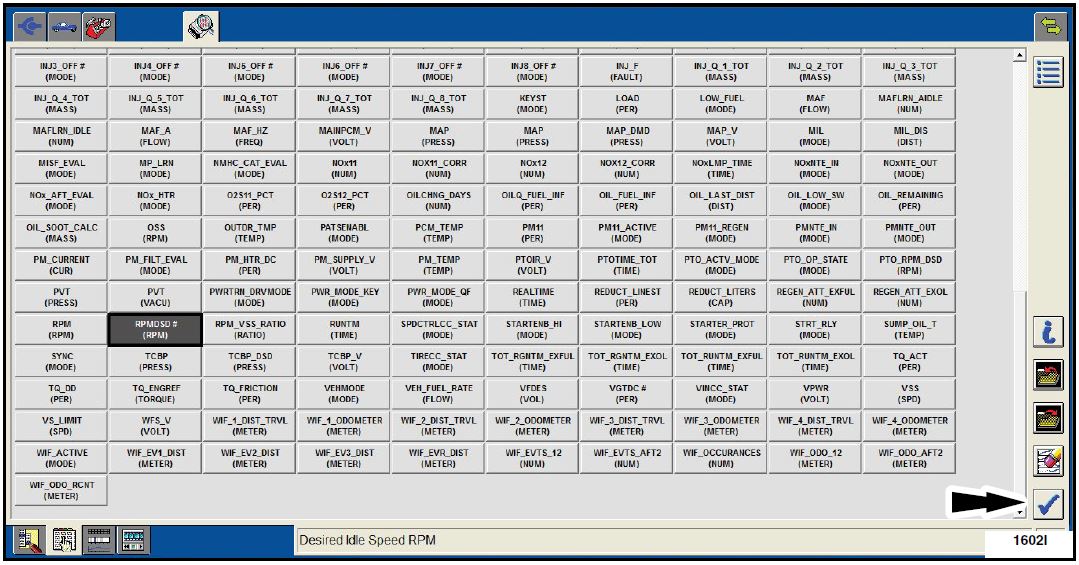

- C. Select the RPMDSD PID. Click the check mark. See Figure 2.

FIGURE 1

FIGURE 2

NOTE: It is not necessary to run the vehicle inside the shop once it has been allowed to warm.

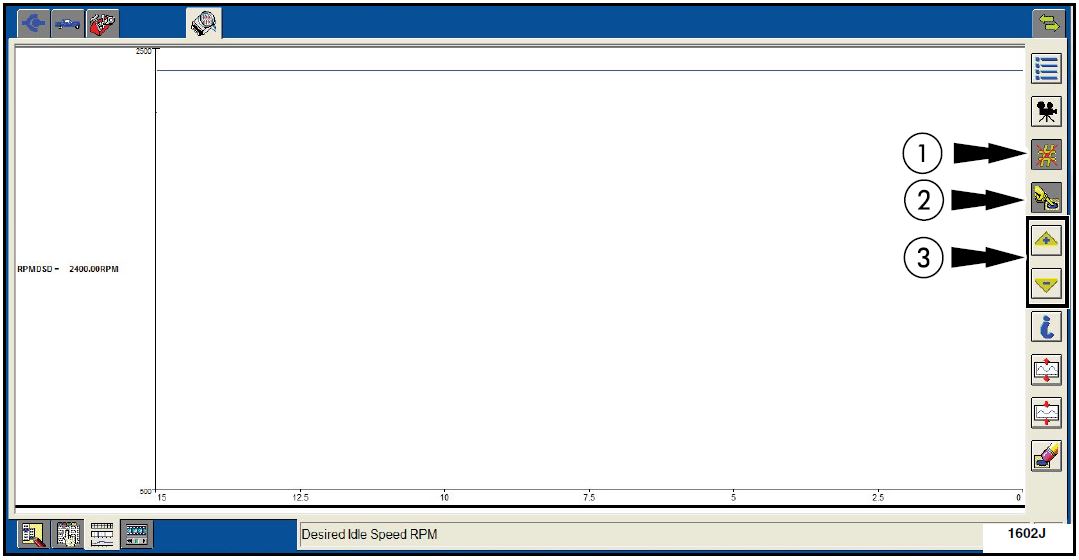

- Start the engine and then select the control function. Use the control function buttons to increase engine RPM between 2,400 to 2,500 RPM for a minimum of 30 minutes. See Figure 3.

FIGURE 3

- Shut off engine at the desired soak location. Allow vehicle to soak for a minimum of 8 hours.

NOTE: Regardless of outside ambient temperatures, the balance of this test procedure may be completed without bringing the vehicle into the shop. The vehicle must NOT be started until the 8 hour soak is completed.

Phase Two

NOTE: If you are repeating Phase Two on a previously tested vehicle, it is not necessary to run the engine at 2,400 to 2,500 RPM for a minimum of 30 minutes again (Phase One).

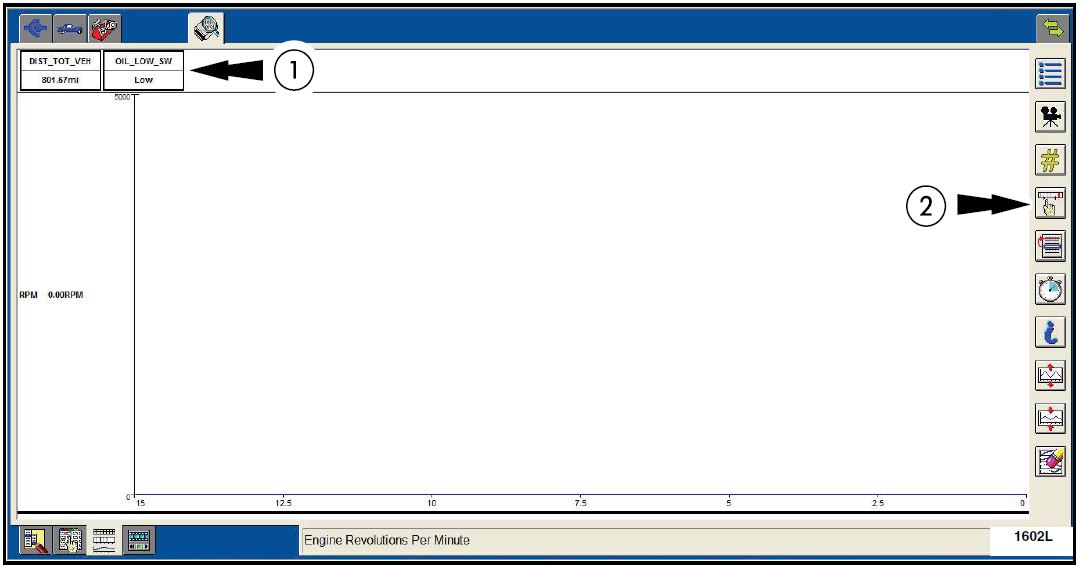

- After 8 hour soak, connect IDS and select Tool Box > Data Logger > Powertrain > Engine.

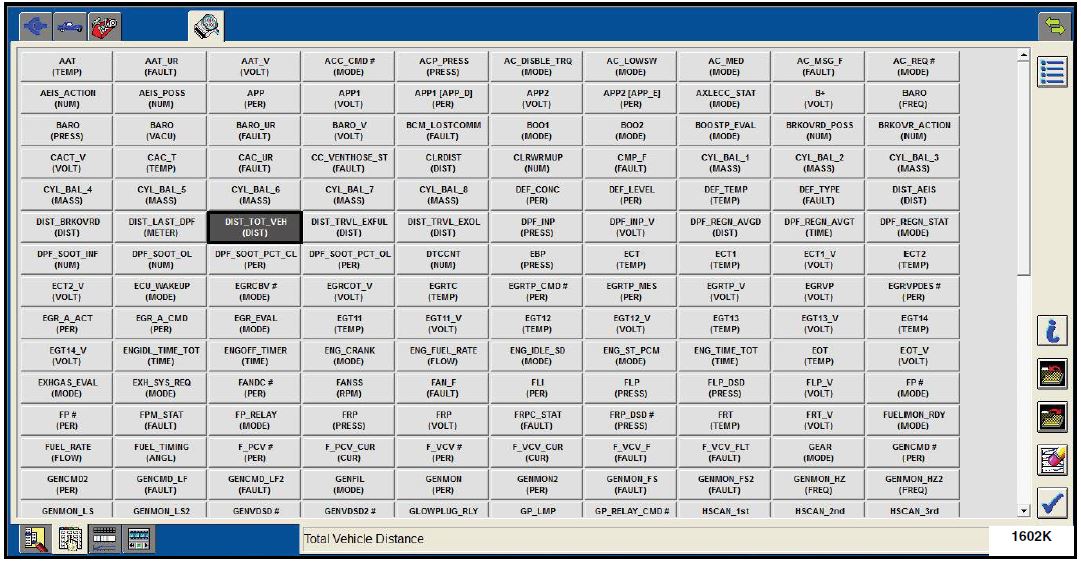

- Clear all pre-selected PID boxes by pressing the clear button in the lower right corner of the screen. See Figure 1.

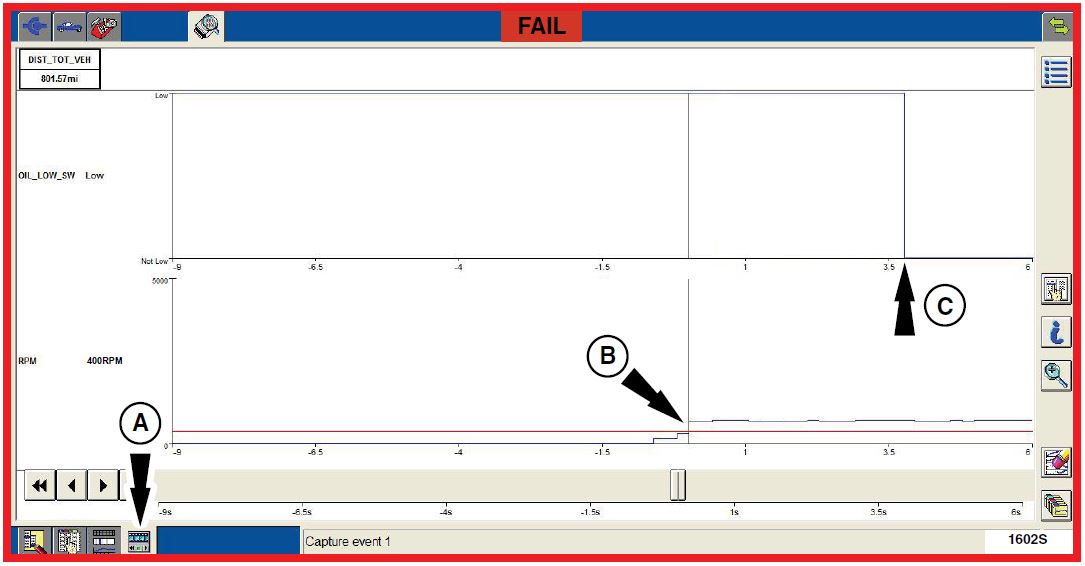

NOTE: Do not start the engine until the DIST_TOT_VEH (DIST) PID, OIL_LOW_SW (MODE) PID and the RPM (RPM) PID are displayed in graph form as shown in Figure 10.

- Select the DIST_TOT_VEH (DIST) PID, OIL_LOW_SW (MODE) PID and the RPM (RPM) PID. Click the check mark. See Figures 4a and 4b.

FIGURE 4a

FIGURE 4b

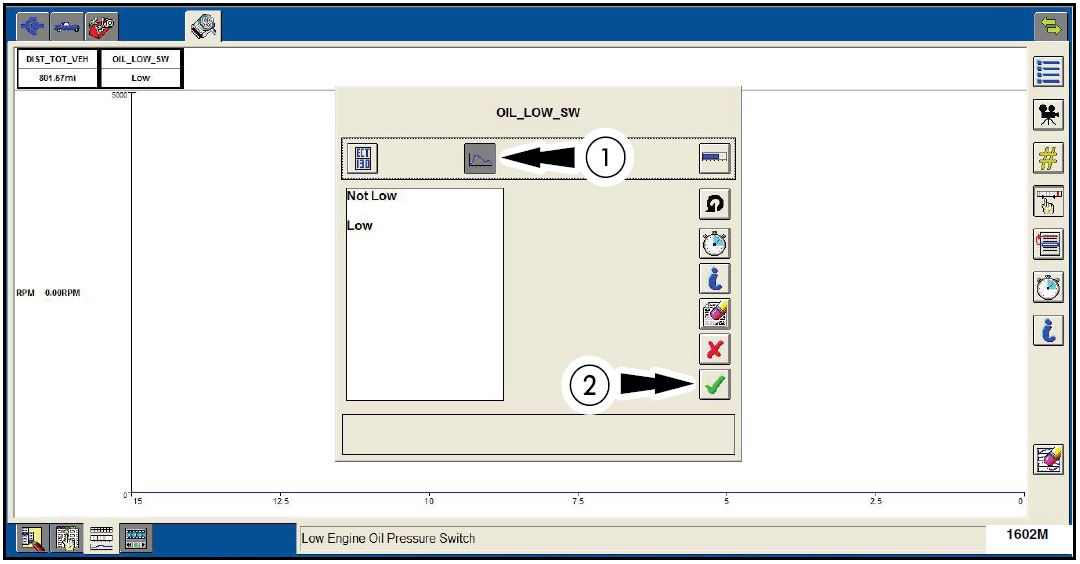

- On the graph screen, select the OIL_LOW_SW PID in the upper LH corner of the screen and then click the plot format button. See Figure 5.

FIGURE 5

- In the OIL_LOW_SW PID dialog box, select the graph button and then click the check mark. See Figure 6.

FIGURE 6

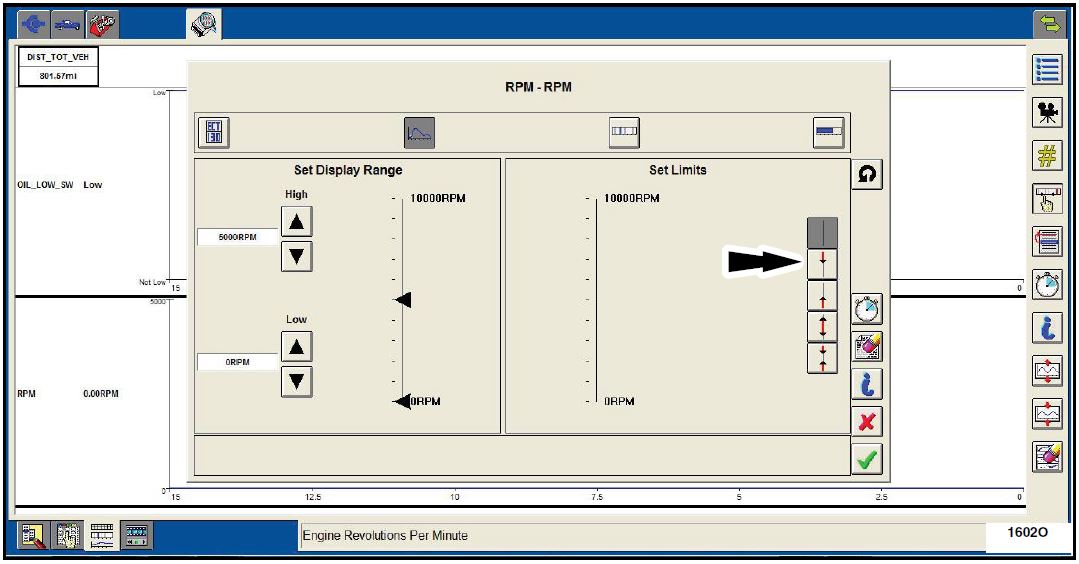

- On the graph screen, select the RPM PID and then click the plot format button. See Figure 7.

FIGURE 7

- In the RPM PID dialog box, select upper limit button. See Figure 8.

FIGURE 8

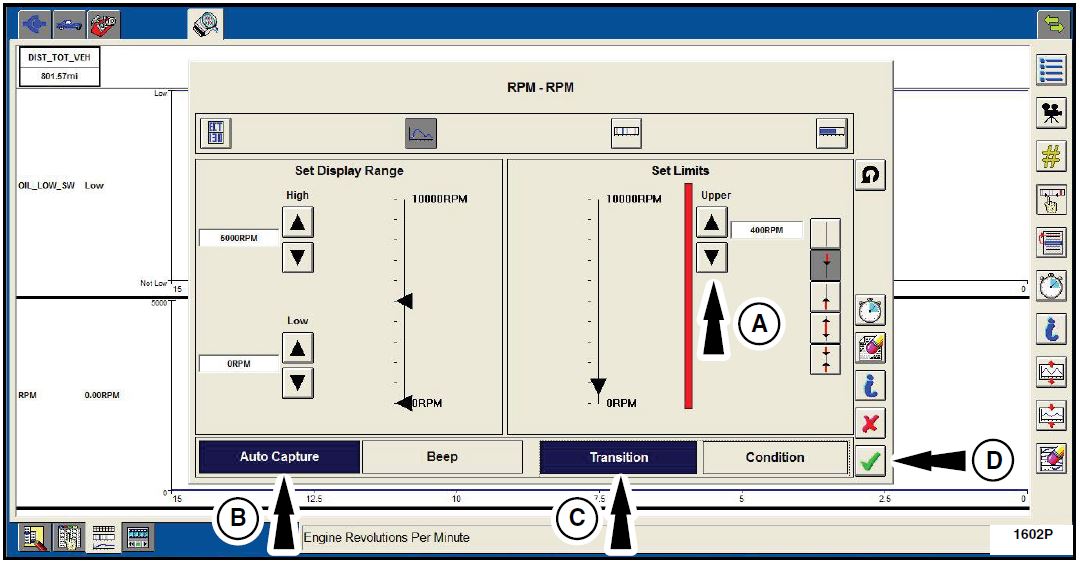

- Set the Auto Capture limits for the RPM PID. See Figure 9.

- A. Under the Set Limits section, press the down arrow until the upper limit is set to 400 RPM.

- B. Select the Auto Capture button.

- C. Select the Transition button.

- D. Click the check mark.

FIGURE 9

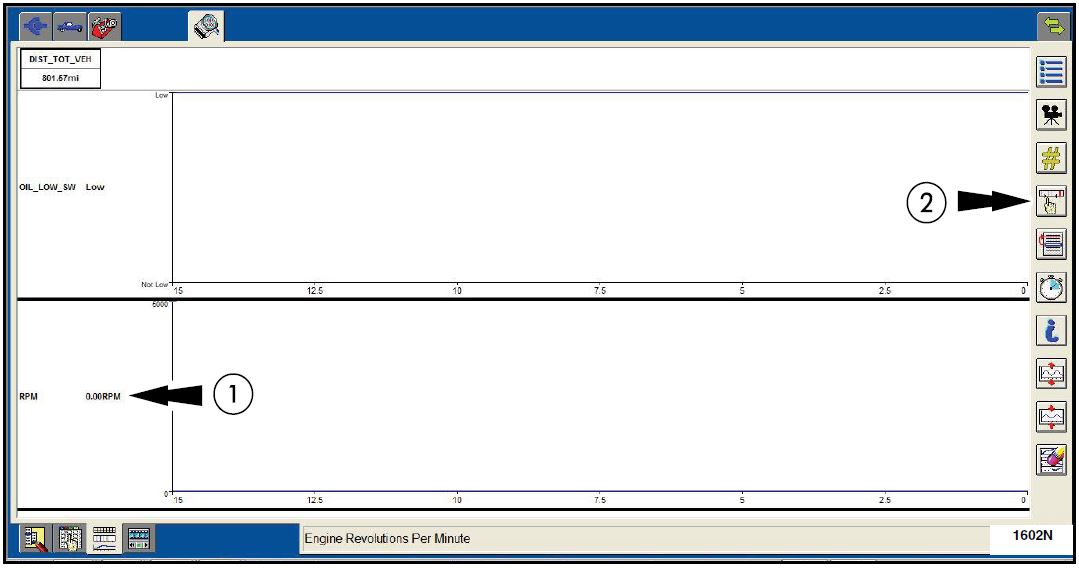

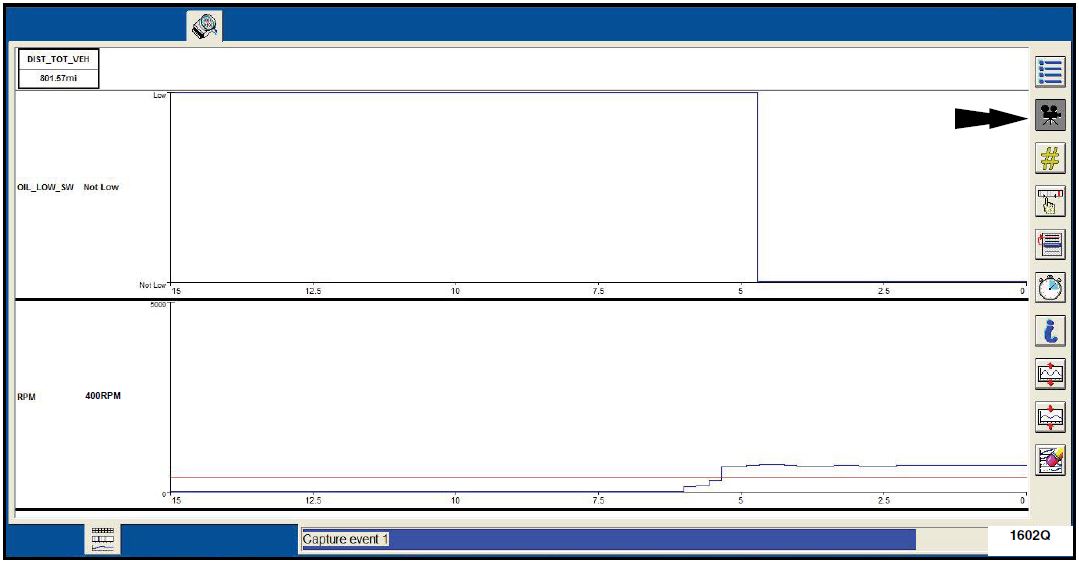

- Once the OIL_LOW_SW (MODE) PID and the RPM (RPM) PID are displayed in graph form, start the engine and the recording will automatically begin when the engine RPM reaches 400. See Figure 10.

NOTE: The data capture button will be automatically selected for you.

FIGURE 10

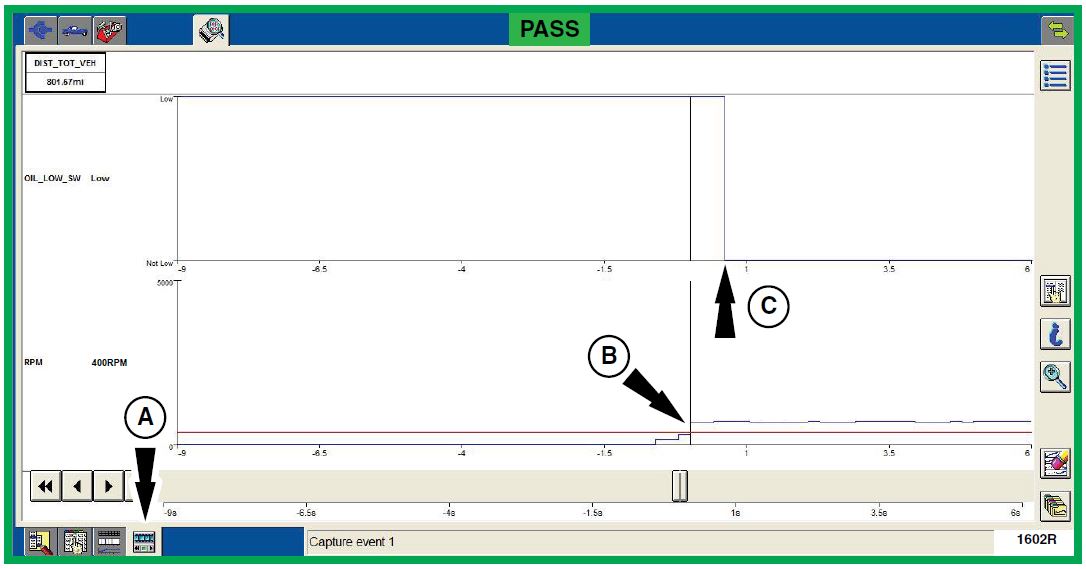

- Evaluate the recording data. See Figures 11 and 12.

- A. Select the Playback Display button to view the IDS recording.

- B. The recording automatically started when the RPM PID crossed the 400 RPM limit. This represents 0 (zero) seconds on the graph.

- C. Observe when the OIL_LOW_SW PID switched from “Low” to “Not Low”.

- If the time is less than 3.25 seconds the inspection is a PASS, no additional service is required.

- If the time is greater than 3.25 seconds the inspection is a FAIL, and the engine front cover must be replaced following the procedures in Workshop Manual (WSM) Section 303-01C.

- To place an order for the engine front cover, submit a VIN-specific Part Order contact via the SSSC Web Contact Site. The Part Order must include a file attachment containing a screen shot of the IDS recording demonstrating the fail condition.

Attachments must be 1MB or smaller. - Send the IDS session file to Ford

. See GSB G0000070 – How To Send An IDS Session File Containing Recordings.

. See GSB G0000070 – How To Send An IDS Session File Containing Recordings.

- To place an order for the engine front cover, submit a VIN-specific Part Order contact via the SSSC Web Contact Site. The Part Order must include a file attachment containing a screen shot of the IDS recording demonstrating the fail condition.

FIGURE 11

FIGURE 12

Loading...

Loading...

Loading...

Loading...