| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10171915

Manufacturer Communication Number: TSB 20-2051

Summary

Some 2017-2018 F-150 vehicles equipped with a 3.5L EcoBoost engine built at Kansas City Assembly Plant on or before 23-Feb-2018 or Dearborn Truck Plant on or before 26-Feb-2018 and Expedition/Navigator vehicles built on or before 19-Mar-2018 may exhibit an oil leak from the oil pan RTV seal. This may be due to a lack of RTV adhesion. This article includes detailed steps to achieve proper RTV adhesion. To correct the condition, follow the Service Procedure steps to replace the oil pan.

This bulletin supersedes 20-2015. Reason for update: Incorrect or Missing Parts

Model:

2017-2018 F-150

2018 Expedition

2018 Navigator

Summary

This article supersedes TSB 20-2015 to update the Parts List.

Issue: Some 2017-2018 F-150 vehicles equipped with a 3.5L EcoBoost engine built at Kansas City Assembly Plant on or before 23-Feb-2018 or Dearborn Truck Plant on or before 26-Feb-2018 and Expedition/Navigator vehicles built on or before 19-Mar-2018 may exhibit an oil leak from the oil pan RTV seal. This may be due to a lack of RTV adhesion. This article includes detailed steps to achieve proper RTV adhesion. To correct the condition, follow the Service Procedure steps to replace the oil pan.

Action: Follow the Service Procedure steps to correct the condition on vehicles that meet all of the following criteria:

- One of the following vehicles:

- 2017-2018 F-150 built at Kansas City Assembly Plant on or before 23-Feb-2018

- 2017-2018 F-150 built at Dearborn Truck Plant on or before 26-Feb-2018

- 2018 Expedition/Navigator built at Kentucky Truck Plant on or before 19-Mar-2018

- 3.5L EcoBoost engine

- Oil leak from oil pan RTV seal

NOTE: Part quantity refers to the number of that service part number required, which may be different than the number of individual pieces. Service part numbers contain 1 piece unless otherwise stated.

Parts

| Description | Quantity | Part Number | |

| – | Oil Pan | 1 | HL3Z-6675-A |

| – | Oil Filter | 1 | AA5Z-6714-A |

| – | Steering Shaft Bolt (2018 F-150) | 1 | N808684S101 |

| – | Steering Shaft Bolt (2018 Expedition/Navigator) | 1 | W702600S439 |

| Package Contains 4

Pieces, 1 Pieces Required | Axle Housing Nut | 1 | W712723S441 |

| Package Contains 4

Pieces, 2 Pieces Required | Axle Housing Bolt | 1 | W712724S439 |

| Package Contains 4

Pieces, 1 Pieces Required | Axle Housing Nut | 1 | W716700S442 |

| Package Contains 4

Pieces, 1 Pieces Required | Axle Housing Bolt | 1 | W712743S439 |

| – | Motorcraft® High Performance Engine RTV Silicone | As Needed | TA-357 |

| – | Motorcraft® Silicone Gasket Remover | As Needed | ZC-30-A |

| – | Motorcraft® Metal Surface Prep Wipes | As Needed | ZC-31-B |

| – | Motorcraft® Metal Brake Parts Cleaner (Compliant With Low Volatile Organic Compound Requirements As Required In Some USA States) | As Needed | PM-4-A |

| – | Motorcraft® Metal Brake Parts Cleaner (Not Compliant With Volatile Organic Compound Requirements) | As Needed | PM-4-B |

| – | Motorcraft® Engine Shampoo and Degreaser | As Needed | ZC-20 |

| – | Motorcraft® SAE 5W-30 Premium Synthetic Blend Motor Oil (All Markets Except Canada) | 6 | XO-5W30Q1SP |

| – | Motorcraft® SAE 5W-30 Super Premium Motor Oil (Canada Only) | 6 | CXO-5W30LSP6 |

Service Procedure

CAUTION: Cleaning and preparation of the engine sealing surface is absolutely critical for proper adhesion of the new oil pan. Improperly cleaned and prepared sealing surfaces will result in an oil leak.

- Remove and discard the oil pan. It is recommended to allow the crankcase to drain overnight to prevent contamination of the engine sealing surface. Refer to the Workshop Manual (WSM), Section 303-01.

- Thoroughly clean the engine sealing surface using Motorcraft® Silicone Gasket Remover and a plastic scraper. Allow the gasket remover to set for several minutes after application to aid in removal of the RTV sealant. Refer to the WSM, Section 303-00.

(1). The engine block skirt stiffener sealing surface must be clean and free of any residual RTV. Do not use metal scrapers, wire brushes, or rotary tools of any type on the engine sealing surface. These tools will cause damage to the sealing surface including scratches or gouges that will create leak paths. A second application of Motorcraft® Silicone Gasket Remover may be required.

CAUTION: When cleaning the engine sealing surface it must be wiped clean using a lint free cloth. Spraying the surface with brake cleaner and air drying will not adequately remove the oil and other contaminates from the surface and may leave residue from the brake cleaner that may interfere with RTV adhesion.

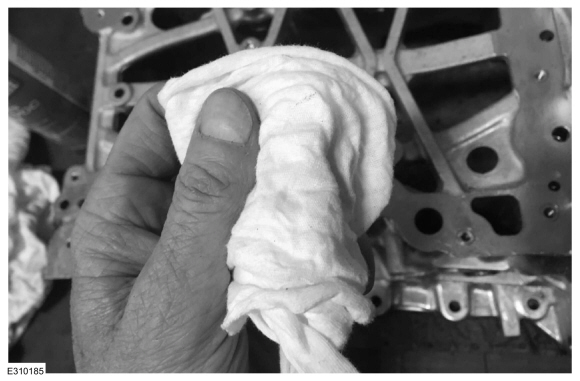

- Use a lint free towel and Motorcraft® Metal Brake Parts Cleaner to remove all residual sealant and oil from the engine sealing surface until a clean lint free towel no longer shows any residual oil when wiping the surface. (Figures 1-2)

(1). Use only Motorcraft® Metal Brake Parts Cleaner to clean the engine sealing surface. Some unapproved brake parts cleaners contain chemicals that will inhibit RTV adhesion or may evaporate without removing all of the residual oil from the sealing surface which will result in a repeat leak condition.

Figure 1

Figure 2

CAUTION: Motorcraft® Engine Shampoo and Degreaser is used to remove residual brake cleaner which can cause RTV failure and prepare the surface for the Motorcraft® Metal Surface Prep Wipes. The use of any other brand engine shampoo or engine cleaner can compromise the sealing surface and could lead to failure of the RTV seal and a fluid leak.

- Use Motorcraft® Engine Shampoo and Degreaser to clean the surface of any remaining oil contamination and prepare the surface for the Motorcraft® Metal Surface Prep Wipes. After Motorcraft® Engine Shampoo and Degreaser, dry the surface with a lint free towel.

CAUTION: Do not use Motorcraft® Metal Surface Prep Wipes on the replacement oil pan. Using Motorcraft® Metal Surface Prep Wipes on the oil pan will contaminate the treated oil pan sealing surface causing reduced RTV adhesion and a potential oil leak.

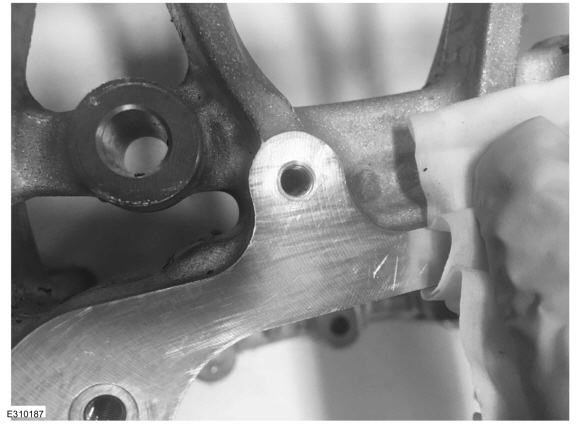

- Wipe the metal engine block skirt stiffener sealing surface using Motorcraft® Metal Surface Prep Wipes. Thoroughly coat the surface with the fluid. Discard wipes after a single use.

(1). Motorcraft® Metal Surface Prep Wipes create a conversion coating providing an improved base for RTV sealing. The fluid is a water-based, slightly acidic solution that will etch and bond to the metal to provide a microscopic layer to which the RTV can adhere. If the surface is oily, the solution will bead and the surface will not be treated properly. If the solution beads when applied to the sealing surface, the surface must be cleaned again and Motorcraft® Metal Surface Prep Wipes reapplied. (Figures 3-4)

Figure 3

Figure 4

NOTE: If the sealing surface or an area of the sealing surface becomes contaminated after it has been prepared, use a lint-free towel soaked in isopropyl alcohol to clean the area. Prepare the area again using Motorcraft® Metal Surface Prep Wipes.

- Allow the surface to air dry for approximately 2 minutes.

(1). Do not dry the surface using any other method. Attempting to dry the surface may result in sealing surface contamination that may cause oil leaks.

NOTE: The oil pan must be installed within 10 minutes of applying the RTV.

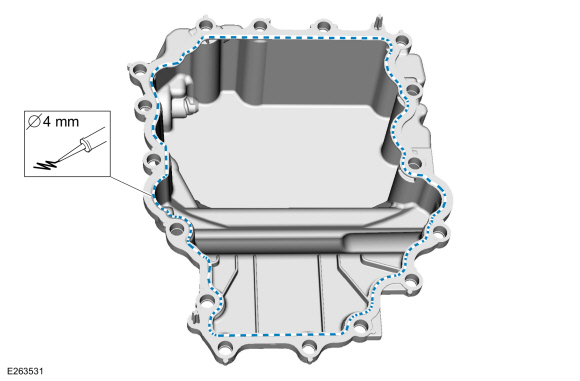

- Apply a 4 mm (0.16 in) bead of Motorcraft® High Performance Engine RTV Silicone to the new oil pan. (Figure 5)

(1). Using too little sealant may result in oil leaks and using too much sealant may result in oil contamination and engine damage.

Figure 5

4 Affected Products

Vehicles

1 Associated Document

Manufacturer Communications

20-2051

25 February 2020

MC-10171915-0001.pdf 538.365KB

Loading...

Loading...

NHTSA ID Number: 10170916

Manufacturer Communication Number: TSB 20-2015

Summary

Some 2017-2018 F-150 vehicles equipped with a 3.5L EcoBoost engine built at Kansas City Assembly Plant on or before 23-Feb-2018 or Dearborn Truck Plant on or before 26-Feb-2018 and Expedition/Navigator vehicles built on or before 19-Mar-2018 may exhibit an oil leak from the oil pan RTV seal. This may be due to a lack of RTV adhesion. This article includes detailed steps to achieve proper RTV adhesion. To correct the condition, follow the Service Procedure steps to replace the oil pan.

1 Associated Document

Manufacturer Communications

20-2015

17 January 2020

MC-10170916-0001.pdf 528.487KB

Loading...

Loading...

- Non-Corrosive Formula - Ultra Black Maximum Oil Resistance Silicone Gasket Maker Is Sensor-safe; With A Non-Corrosive Formula Designed For Superior Adhesion To Oily Surfaces And Long Term Durability

- Superior Resistance - Powertrain Fluids Including Engine Oil, Transmission Fluid, Gear Lube And Coolants To Keep Your Application Locked In Place To Create A Strong Long Lasting Seal

- High Flexibility - Ultra Black Silicone Gasket Maker Retains High Flexibility And Oil Resistant Properties And Can Be Used To Replace Pre Cut Gaskets Or Be Used As A Gasket Maker Or Gasket Sealant

- Long-lasting And Durable - Ultra Black Resists Aging, Weathering And Thermal Cycling Without Hardening, Shrinking Or Cracking. With A Temperature Range Of -65°f To 500°f (-54°c To 260°c) Intermittent

- Suggested Applications: Valve Covers And Valve Guides, Oil Pans, Transmission Pans, Intake Manifold End Seals, Timing Gear Covers, And Differential Covers

- Professional Formula - This Clear Silicone Adhesive Sealant is a Sensor-Safe, General Purpose Clear RTV Sealant that can be used inside or outside for all your jobs

- Do It All- Seal, Bond, Repair, Mend And Secure Glass, Metal, Plastics, Fabric, Vinyl, Weather Stripping, Vinyl Tops, And More With This Clear Rtv Silicone Sealant

- Resist The Elements- Permatex Clear Silicone Adhesive Sealant Is Waterproof And Flexible, Resists Water, Weather, And Vibration On All Your Applications

- Multipurpose Formula- With A Temperature Range From : -75°f To 400°f (-59°c To 204°c) Clear RTV Silicone Can Be Used All Around And Can Be Used To Protect And Repair Electrical Wiring

- Suggested Applications- Door Frames, Seams And Roofs, Vinyl Tops, Windshields, Housings And Coverings, (Not Recommended For Engine Gasket Applications)

- High Performance Formula - Ultra Grey Silicone Gasket Maker is Sensor-Safe, With a Non-Corrosive Formula Designed to Provide Reliable “Formed-in-Place” Gaskets for Mechanical Assemblies

- Vibration Resistant - Permatex Ultra Grey Offers Maximum Vibration Resistance, Withstanding High Torque Loads While Creating a Tough, Flexible, Silicone Rubber Gasket

- Long-Lasting Durable Silicone Gasket - Resists Aging, Weathering, and Thermal Cycling Without Hardening, Shrinking, or Cracking with Temperature Resistance from -65°F to 500°F (-54°C to 260°C).

- Multi-Purpose Gasket Material - Ultra Grey Silicone Gasket Maker Retains High Torque and Vibration Resistance and Can Be Used to Replace Pre Cut Gaskets or Be Used as a Gasket Maker or Gasket Sealant

- Suggested Applications: Valve Covers, Water Pump Housings, Intake Manifold End Seals, Thermostat Housings, Timing Gear Covers, Transmission Pans, and Oil Pans

- Professional Formula - This Black Silicone Adhesive Sealant Is A Sensor-safe, General Purpose Black RTV Sealant That Can Be Used Inside Or Outside For All Your Jobs

- Do It All- Seal, Bond, Repair, Mend And Secure Glass, Metal, Plastics, Fabric, Vinyl, Weather Stripping, Vinyl Tops, And More With This Black RTV Silicone Sealant

- Resist The Elements- Permatex Black Silicone Adhesive Sealant Is Waterproof And Flexible; Resists Water, Weather, And Vibration On All Your Applications

- Multipurpose Formula- With A Temperature Range From -75°f To 450°f (-59°c To 232°c) Black RTV Silicone Can Be Used All Around And Can Be Used To Protect And Repair Electrical Wiring

- Suggested Applications- Door Frames, Electrical Connections, Seams And Roofs, Vinyl Tops, Weather Stripping, Housings And Coverings, (not Recommended For Engine Gasket Applications)

- High flexibility and oil resistance

- Sensor-safe, non-corrosive formula

- Resist to powertrain fluids

- Eliminates the need for pre-formed, pre-cut gaskets

- OEM specified and approved for dealership warranty requirements

- Clear Silicone Sealant & Adhesive: Is A General Purpose Sealant Adhesive, Rtv (Room Temperature Vulcanized)Silicone Designed For Use In Household Or Mechanical Assembly Applications.

- 100% WATERPROOF: This 100% silicone formula offers ultimate protection from water damage, providing a reliable seal in areas prone to consistent water exposure

- UV Protection and 50 Years Durability Guarantee: No Yellow No Color Change

- No Odor = No Smell

- 30-MINUTE WATER-READY: Ready for water exposure in as little as 30 minutes

- SHRINK & CRACK-PROOF: Withstands extreme expansion or contraction associated with temperature fluctuations

- Formulated For Hi-Temp Applications, Or Heavy-Duty Use

- Replaces Almost Any Cut Gasket, And Coats Pre-Cut Gaskets To Increase Reliability

- Makes Reliable 'Formed-In-Place' Gaskets That Resist Cracking, Shrinking And Migrating

- Temperature Range Of -65F To 650F Intermittent

- Adhesives & Sealants

- Country of manufacture: United States

- Manufacturer: Pro-Seal

- Package Weight: 0.11 kilograms

- J-B Weld Hi-Temp Red Silicone Gasket Maker and Sealant is an RTV Silicone gasketing material, designed for use in mechanical assemblies where the existence of higher, continuous temperatures up 650°F.

- Upon curing, which occurs when the product is exposed to the moisture in air, the silicone forms a tough, waterproof seal on most surfaces.

- It will not shrink or crack, resists weathering, and is great for many automotive applications.

- Great for oil pans, valve covers, exhaust manifolds, differential covers and more

SEOCONTENT-START

Warranty Status: Eligible under provisions of New Vehicle Limited Warranty (NVLW)/Service Part Warranty (SPW)/Special Service Part (SSP)/Extended Service Plan (ESP) coverage. Limits/policies/prior approvals are not altered by a TSB. NVLW/SPW/SSP/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool. Labor Times Operation Description Time No. 2017 F-150 4X2 3.5L EcoBoost: Inspect And Replace The Engine Oil Pan (Do Not 202051A 3.2 Use With Any Other Labor Operations) Hrs. F-150 4X4 3.5L EcoBoost: Inspect And Replace The Engine Oil Pan (Do Not 202051B 6 Use With Any Other Labor Operations) Hrs. Expedition/Navigator/F-150 4X2 3.5L EcoBoost: Inspect And Replace The 202051C 3 Engine Oil Pan (Do Not Use With Any Other Labor Operations) Hrs. 2018 Expedition/Navigator/F-150 4X4 3.5L EcoBoost: Inspect And Replace The 202051D 2.9 Engine Oil Pan (Do Not Use With Any Other Labor Operation) Hrs. Repair/Claim Coding Causal Part: 6675 Condition Code: D8

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.