| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10212177

Manufacturer Communication Number: TSB-17-0044

Summary

EXHAUST ODOR IN VEHICLE

Explorer

Explorer

2 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

FORD | EXPLORER | 2016-2017 |

FORD :

:

2016-2017 Explorer

ISSUE:

Some 2016-2017 Explorer/Police Utility vehicles may exhibit an exhaust odor in the vehicle while the climate control system is in auto or recirculation mode. This may be more pronounced after a hard acceleration, driving in hilly conditions and/or towing a trailer. Customers may indicate the odor smells like sulfur. Whether and to what extent any customer or occupant of a 2016-2017 Explorer vehicle experiences the exhaust odor will be affected by driving habits, weather and individual sensitivities.

ACTION:

Follow the Service Procedure steps to improve the condition.

SERVICE PROCEDURE

- Does the vehicle have upfitter (Police or other aftermarket) content installed?

- No – proceed to Non Police/Aftermarket Upfitter Service Procedure.

- Yes – proceed to Police/Aftermarket Up-fitter Service Procedure.

Police/Aftermarket Upfitter Service Procedure

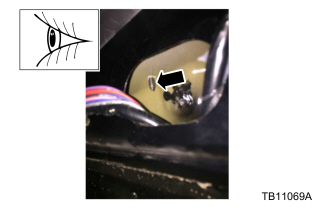

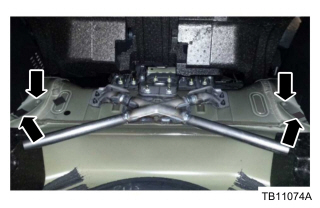

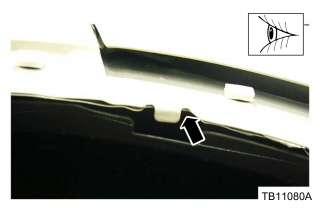

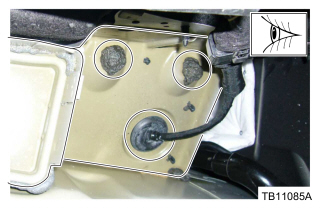

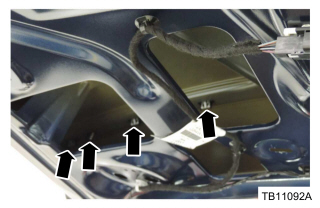

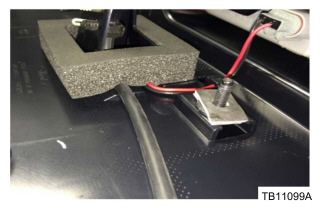

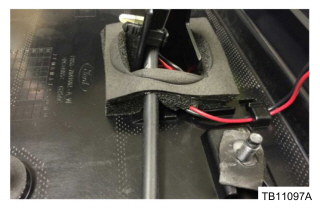

Any hole or added fasteners in the body must be thoroughly and permanently sealed with Motorcraft Seam Sealer or foil backed mastic patch. (Figure 1)

1. Inspect all pass through locations created for wiring and brackets. Areas commonly affected by aftermarket upfitters include but are not limited to the following:

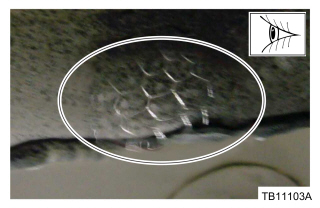

a. Liftgate outer sheet metal.

b. Liftgate primary seal.

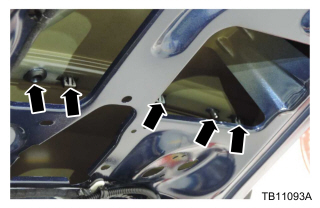

c. Rear end sheet metal.

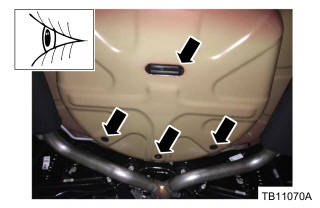

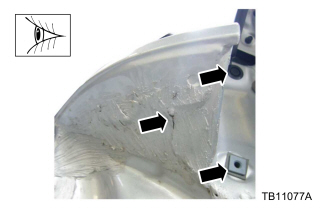

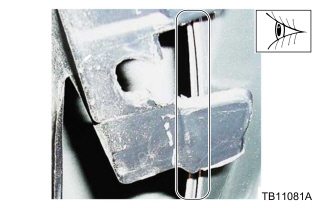

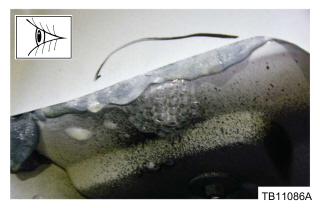

d. Rear end underbody sheet metal/body plugs. (Figure 2)

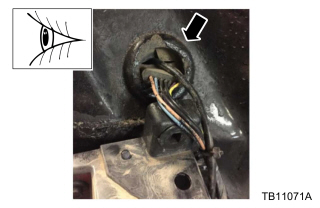

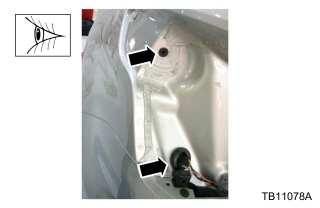

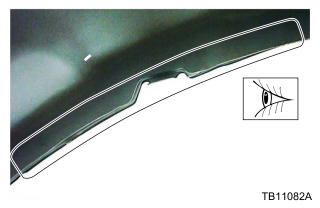

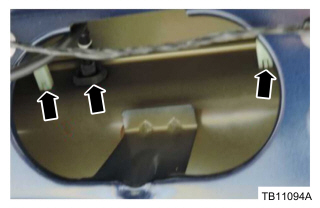

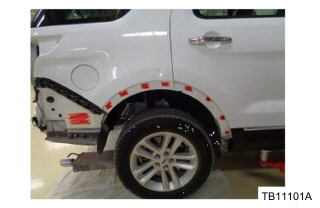

e. Behind left and right rear lamp assemblies. (Figure 3)

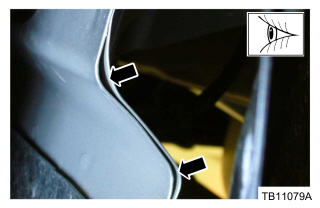

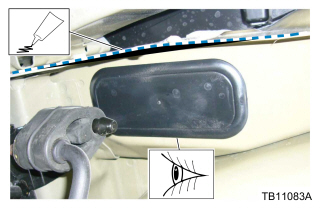

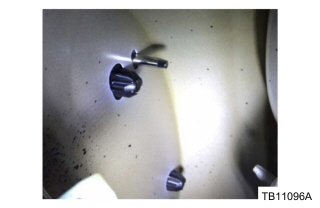

f. Spoiler attachment to the liftgate sheet metal. Improper spoiler sealing. (Figure 4)

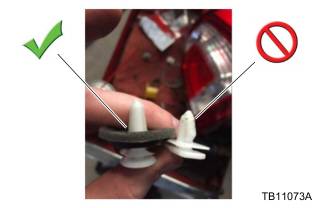

(1) Correct spoiler to liftgate fastener (left) incorrect fastener (right) (Figure 5)

g. Rear load floor bolt holes (may require removal of hardware and/or electronics). Under the rear load floor there are 4 threaded bolt holes (2 on the left side and 2 on the right). On police units with no third row seat the front bolt hole is used to secure the load floor. The rear load floor bolt hole on each side should be sealed with mastic patch. (Figure 6)

(1) Verify that patches are present over the rear hole on the left and right sides. Complete removal of the load floor may not be required. Remove the two fasteners and partially raise the load floor to inspect for the mastic patch. Seal with mastic patch if not present.

2. Proceed to Non Police/Aftermarket Up-fitter Procedure.

Non Police/Aftermarket Up-fitter Service Procedure

The Non Police/Aftermarket Up-fitter Service Procedure consists of 2 separate repair routines. Most vehicles will not require the second procedure.

Non Police/Aftermarket Up-fitter Service Procedure 2 does not apply to vehicles equipped with the 3.7L Twin independent-variable camshaft timing (Ti-VCT), 2.3L gasoline turbocharged direct injection (GTDI) or 3.5L GTDI engines.

The body sealing steps in this procedure are critical elements in helping to manage subjective odor concerns.

1. Is the customer returning with the exhaust odor complaint after Non Police/Aftermarket Up-fitter Procedure 1 was completed?

a. No – proceed to Non Police/Aftermarket Up-fitter Procedure 1.

b. Yes – is the vehicle equipped with the 3.5L Ti-VCT engine?

(1) Yes – proceed to Non Police/Aftermarket Up-fitter Procedure 2.

(2) No – the procedure does not apply. Continue with normal diagnostics.

Non Police/Aftermarket Upfitter Service Procedure 1

1. Reprogram the heating ventilation air conditioning (HVAC) module to the latest calibration using IDS release 105.01 or higher. Make sure you are connected to the internet when entering module programming to obtain the latest updates. Calibration files may also be obtained at www.motorcraftservice.com.

a. When reprogramming the HVAC, IDS will have additional questions which will require a yes response to reprogram the module.

2. Visually inspect the rear liftgate weatherstrip seal.

a. Check for a seal contact mark around the entire liftgate sealing surface. View the weatherstrip contact mark from different angles to make sure that it can be seen clearly. The appearance of a slight gap at the bottom center of the liftgate near the latch area is normal and corresponds with the weatherstrip joint seam. Refer to Workshop Manual (WSM), Section 501-03 to reposition the liftgate as required to obtain a proper seal. (Figure 7)

3. Make sure the three (3) liftgate drain plugs are in place and installed correctly on the liftgate. (Figure 8)

a. Reposition any incorrectly installed drain plugs.

4. Remove the left and right rear lamp assemblies. Refer to WSM, Section 417-01.

5. Inspect the horizontal and vertical surfaces of the rear lamp mounting area for holes in the body sealer. Verify all body plugs and plastic anchor nuts are properly installed. (Figure 9)

6. Verify all rear lamp mounting and wiring harness grommets are sitting flush against the body.

a. Inspect for excess body sealer beneath the grommet preventing it from fully seating thereby creating a leak. (Figure 10)

b. Remove any excess body sealer and seal the grommet.

7. Remove the right and left rear quarter panel mouldings. Refer to WSM, Section 501-08.

8. Remove the right and left rear quarter panel splash shields. Refer to WSM, Section 501-08.

9. Inspect the joined lower inner panels for gaps and/or missing sealer.

a. Inspect the lower edge of the wheel arch for gaps. Seal as necessary using Motorcraft Seam Sealer or equivalent. (Figure 11)

b. Inspect the upper edge of the wheel arch for gaps. Seal as necessary using Motorcraft Seam Sealer or equivalent. (Figure 12)

c. Inspect the lower front edge of the wheel arch for gaps. Seal as necessary using Motorcraft Seam Sealer or equivalent. (Figure 13)

d. Inspect the backside of the upper wheel arch area for gaps. Seal as necessary using Motorcraft Seam Sealer or equivalent. (Figure 14)

10. Remove the rear bumper cover. Refer to WSM, Section 501-19.

11. Inspect the rear underbody spare tire pan plugs and verify plugs are properly installed. (Figure 2)

12. Inspect the left and right rear rectangular underbody plugs and verify plugs are properly installed. (Figure 15)

13. Seal the entire length of the seam that runs rearward of the body plugs.

a. Left side shown, right side similar. (Figure 15)

14. Closely inspect the left and right side boxed sections of the vehicle underbody. Inspect for gaps and/or missing body sealant at joined panels that may allow air to pass through. (Figure 16)

a. If any gaps or missing body sealant are found, seal with Motorcraft Seam Sealer or equivalent.

15. Inspect the seams of all joined panels at the rear underside of the vehicle for any gaps or missing seam sealer. (Figure 17)

a. If any gap and/or missing body sealer is present, enough that may allow air to pass through, seal with Motorcraft Seam Sealer or equivalent.

16. Inspect the area behind the wheel arch and reseal if necessary. (Figure 18)

a. A leak in this area may only show up during a cabin pressurization test.

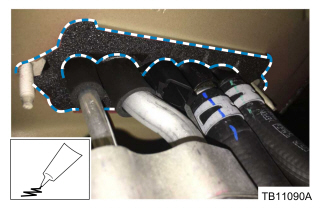

17. Locate the wiring/grommet in the right rear floor area (Figure 19)

a. Thoroughly wrap the wiring harness with Rotunda Coroplast electrical wire harness tape where the 3 leads meet underneath the vehicle, up to the grommet to completely seal the harness.

b. Wrap approximately 6 inches of the wiring harness on the vehicle interior side of the harness up to the grommet using Rotunda Coroplast electrical wire harness tape. (Figure 20)

c. Make sure the grommet is fully seated and seal if necessary with Motorcraft Seam Sealer. (Figure 21)

18. Inspect the rear evaporator inlet line seal where the evaporator lines enter the vehicle. Make sure the foam seal is undamaged and fully seated with no gaps between the seal and the body and the seal and the evaporator pipes.

a. Rear evaporator inlet line seal viewed from underneath . Inspect for gaps and seal if needed with Motorcraft Seam Sealer. (Figure 22)

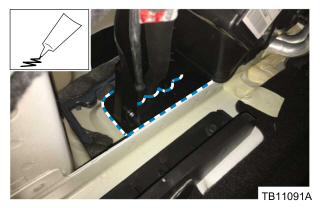

b. From inside the vehicle, remove the driver side load space trim panel to reveal the rear A/C evaporator lines. Refer to WSM, Section 501-05. Apply Motorcraft Seam Sealer between the lines and in any gaps to thoroughly seal the pass through. (Figure 23)

19. Remove the lower liftgate interior trim panel. Refer to WSM, Section 501-05.

20. From inside the vehicle locate the applique, Ford name plate and license plate attachments and apply sealant from the inside using Motorcraft Seam Sealer or equivalent.

name plate and license plate attachments and apply sealant from the inside using Motorcraft Seam Sealer or equivalent.

a. Rear applique attachments, left side. (Figure 24)

b. Rear applique attachments, right side. (Figure 25)

c. Rear applique attachments, center. (Figure 26)

d. Rear license plate attachments. (Figure 27)

e. Ford name plate. (Figure 28)

name plate. (Figure 28)

21. Remove the rear spoiler. Refer WSM, Section 501-08.

22. Inspect the foam tower seal and make sure the wiring and washer line are routed properly and are not compromising the sealing interface. There are two designs of the tower foam. Both designs are acceptable to use. (Figures 29-30)

a. Washer line routed improperly. Line is not seated between locating tabs and sealing foam highly compressed. (Figures 31-32)

b. Washer line routed properly. Line is seated in locating tabs and sealing foam relaxed. (Figure 29)

c. Repair and reseal as necessary using Motorcraft Seam Sealer or equivalent

23. Replace the plastic spoiler retention w-clips with the clips and foam washers from the spoiler service kit.

24. Inspect the liftgate sheet metal for distortion at the 4 clip locations and flatten with a rubber mallet as needed. Reinstall the spoiler. Refer to WSM, Section 501-08.

25. Pressure test the cabin for any additional leaks.

a. Before beginning the pressurization process, allow all recently sealed areas to dry for 30 minutes.

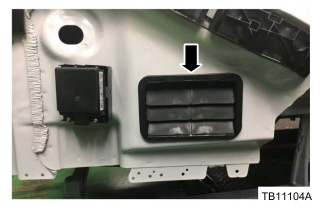

b. Using masking tape, seal the rear air extractors and any fascia or trim attachment holes. (Figures 33-34)

c. Start the vehicle, set the front A/C to fresh air mode and set the front blower speed to maximum.

d. Close all doors and make sure windows are fully closed.

e. Use soapy water in a spray bottle to help locate air leaks. Spray around the following areas:

(1) Underbody seams

(2) Rear decklid seals

(3) Underbody rubber grommet

(4) Side panel glass seals

(5) Rear wheel well seams

(6) Rear tail light seams

(7) License plate area

26. Air leaks can be identified by the presence of air bubbles. (Figure 35)

27. Mark all areas identified to have air leaks.

28. Turn off A/C.

29. Turn off vehicle.

30. Clean and dry all areas marked earlier.

31. Seal using Motorcraft Seam Sealer or equivalent.

32. Allow sealant to dry for 30 minutes and retest.

33. Remove the masking tape applied in Step 25.

34. Inspect the left and right side air extractors for proper fit to the body and operation/sealing of the rubber flaps.

a. Replace the air extractor if it is warped or damaged or flaps do not lay flush to their sealing surface. (Figure 36)

35. Reinstall rear bumper cover. Refer to WSM, Section 501-19.

36. Reinstall right rear and left rear quarter panel splash shields.

a. Installation of the rear quarter panel splash shields requires two (2) rivets per side.

37. Reinstall the right rear and left rear quarter panel moulding. Refer to WSM, Section 501-08.

38. Reinstall the stoplamp assemblies. Make sure they are not installed over the liftgate seal. Refer to WSM, Section 417-01.

39. Reinstall the liftgate and load space trim panels. Refer to WSM, Section 501-05.

Non Police/Aftermarket Upfitter Service Procedure 2

1. Click here to access Guided Routine. Does the vehicle meet necessary conditions?

a. Yes – proceed to Step 2.

b. No – return the vehicle to the customer. No additional repairs are available.

2. Inform the customer of the redesigned exhaust tips and the appearance will remain the same but the exhaust will exit the tip from bottom. Upon acceptance, replace the muffler assembly with the updated part containing the downturned exhaust tips. Refer to WSM, Section 309-00. (Figures 37-38)

Obtain Part Locally

| Part Number | Part Description |

| NAI837X |

Rotunda Coroplast Electrical Wire Harness Tape |

| PART NUMBER | PART NAME |

| BB5Z-61280B62-B | Air Extractor |

| FB5Z-7829164-AA | Quarter PanelMoulding Right Side |

| FB5Z- 7829165-AA |

Quarter PanelMoulding Left Side |

| W-706092-S300 | Splash Shield Rivets |

| TA-2-B |

Motorcraft Seam Sealer |

| FB5Z-78442K03-B | Spoiler Service Kit |

| 4M8Z-54280B62-A |

Liftgate Drain Valve Assembly |

| 4L3Z-18203A16-AA |

Foil-Backed Mastic Patch |

| FB5Z-5230-B | Muffler Assembly |

1 Associated Document

Manufacturer Communications

TSB 17-0044

SB-10212177-1234.pdf 7516.49KB

Loading...

Loading...

- Bonds to All Surfaces: Our seam sealer automotive formula bonds strongly with primed, painted, or bare metal surfaces, offering a fast curing solution. Ready for paint in just 30 minutes, it serves as an effective RV roof sealant and polyurethane auto body filler without the need for sanding.

- All-Weather Performance: Designed to deliver a long-lasting seal, our automotive seam sealer withstands extreme weather without shrinking or cracking. Seam seal technology ensures it remains flexible and durable for both indoor and outdoor applications, making it a versatile automotive sealant.

- Easy Application & No Prep Needed: Seamlessly compatible with any standard urethane caulk gun, this auto glass sealant offers excellent adhesion without the need for surface prep. Our car seam sealer ensures quick and professional-grade gap filling.

- Versatile Application Across Vehicles: Perfect as car body filler for boats, trucks, and RVs, this automotive paintable seam sealer ensures a seamless fit on body panel and seams. Acting as an RV seam sealer, it meets diverse automotive repair needs effectively.

- Professional Results Guaranteed: Trusted by auto repair experts across the USA, our auto body seam sealer ensures high-quality, professional repairs with every use. Satisfaction guaranteed—see the difference in your repairs!

- [2-Pack] Plug Any Void –– Easily patch large cracks with confidence when using this thick auto seam sealer. This single-component panel bond compound provides superior adhesion on bare, primed, or painted metal surfaces on your vehicle or RV. Seam sealer is black in color.

- Complete Kit –– Comes with nitrile gloves and an application tip to make the process ...seamless. This joint and seam filler set comes with everything you need and more. The sealant is compatible with any standard caulking gun

- Permanently Fill Gaps –– Don't settle for a body panel adhesive sealant that doesn't hold up. Trust in a non-shrinking, non-cracking and low odor formula that stays remarkably flexible over time. Prevent leaks and debris from infiltrating your vehicle, and promote corrosion resistance

- Primer and Paint Ready –– Get your project ready for the road in just 24 hours. Smooth out and let the quick-curing seam sealant settle in for 45 minutes. Then you're ready to prime and paint the automotive body filler for a flawless finish that blends right in. Seam sealer is black in color.

- All-Weather Performance –– High heat and humidity are no match for this car sealant. Enhanced moisture curing properties ensure a durable hold for interior or exterior use. Use a urethane sealer that is worlds ahead of any solvent-based solutions

- Bonds to All Surfaces: Our seam sealer automotive formula bonds strongly with primed, painted, or bare metal surfaces, offering a fast curing solution. Ready for paint in just 30 minutes, it serves as an effective RV roof sealant and polyurethane auto body filler without the need for sanding.

- All-Weather Performance: Designed to deliver a long-lasting seal, our automotive seam sealer withstands extreme weather without shrinking or cracking. Seam seal technology ensures it remains flexible and durable for both indoor and outdoor applications, making it a versatile automotive sealant.

- Easy Application & No Prep Needed: Seamlessly compatible with any standard urethane caulk gun, this auto glass sealant offers excellent adhesion without the need for surface prep. Our car seam sealer ensures quick and professional-grade gap filling.

- Versatile Application Across Vehicles: Perfect as car body filler for boats, trucks, and RVs, this automotive paintable seam sealer ensures a seamless fit on body panel and seams. Acting as an RV seam sealer, it meets diverse automotive repair needs effectively.

- Professional Results Guaranteed: Trusted by auto repair experts across the USA, our auto body seam sealer ensures high-quality, professional repairs with every use. Satisfaction guaranteed—see the difference in your repairs!

- Plug Any Void –– Easily patch large cracks with confidence when using this thick auto seam sealer. This single-component panel bond compound provides superior adhesion on bare, primed, or painted metal surfaces on your vehicle or RV

- Complete Kit –– Comes with nitrile gloves and an application tip to make the process seamless This joint and seam filler set comes with everything you need and more. The sealant is compatible with any standard caulking gun

- Permanently Fill Gaps –– Don't settle for a body panel adhesive sealant that doesn't hold up. Trust in a non-shrinking, non-cracking and low odor formula that stays remarkably flexible over time. Prevent leaks and debris from infiltrating your vehicle, and promote corrosion resistance

- Primer and Paint Ready –– Get your project ready for the road in just 24 hours. Smooth out and let the quick-curing seam sealant settle in for 45 minutes. Then you're ready to prime and paint the automotive body filler for a flawless finish that blends right in

- All-Weather Performance –– High heat and humidity are no match for this car sealant. Enhanced moisture curing properties ensure a durable hold for interior or exterior use. Use a urethane sealer that is worlds ahead of any solvent-based solutions

- EASY APPLICATIONS: Brushable and paintable consistency

- HIGH ADHESION: Works on both bare metal and painted surfaces

- FAST SKINNING: Starts in about 10 to 15 minutes

- STAYS IN PLACE: Less likely to drip, sag or run out of gaps being sealed

- NON-STAINING: For all-purpose autobody joint and seam sealing

- Permanent Repairs – Seal seams and fix holes in tents, tarps, awnings, rainflies, and gear like Thermarest sleeping pads with a flexible, waterproof adhesive.

- Covers 12 Feet of Seams – One 1 oz tube treats up to 12 feet of seams or patches torn fabric: 8 oz size also available for larger repair needs.

- Durable & Flexible Seal – Cures into a rubber seal that flexes with fabric, bonds to nylon, polyester, canvas, leather, and vinyl for long-lasting performance.

- Won’t Peel or Crack – Designed to stay put through heavy use and weather; ideal for re-proofing or fixing gear that needs to stay waterproof.

- Easy Application – Comes with applicator brush for precise, mess-free repairs at home or in the field.

- Plug Any Void –– Easily patch large cracks with confidence when using this thick auto seam sealer. This single-component panel bond compound provides superior adhesion on bare, primed, or painted metal surfaces on your vehicle or RV

- 2 Pack Value & Complete Kit - Comes with nitrile gloves and an application tip to make the process seamless This joint and seam filler set comes with everything you need and more. The sealant is compatible with any standard caulking gun

- Permanently Fill Gaps - Don't settle for a body panel adhesive sealant that doesn't hold up. Trust in a non-shrinking, non-cracking and low odor formula that stays remarkably flexible over time. Prevent leaks and debris from infiltrating your vehicle, and promote corrosion resistance

- Primer and Paint Ready - Get your project ready for the road in just 24 hours. Smooth out and let the quick-curing seam sealant settle in for 45 minutes. Then you're ready to prime and paint the automotive body filler for a flawless finish that blends right in

- All-Weather Performance - High heat and humidity are no match for this car sealant. Enhanced moisture curing properties ensure a durable hold for interior or exterior use. Use a urethane sealer that is worlds ahead of any solvent-based solutions

- Bonds to All Surfaces: Our seam sealer automotive formula bonds strongly with primed, painted, or bare metal surfaces, offering a fast curing solution. Ready for paint in just 30 minutes, it serves as an effective RV roof sealant and polyurethane auto body filler without the need for sanding.

- All-Weather Performance: Designed to deliver a long-lasting seal, our automotive seam sealer withstands extreme weather without shrinking or cracking. Seam seal technology ensures it remains flexible and durable for both indoor and outdoor applications, making it a versatile automotive sealant.

- Easy Application & No Prep Needed: Seamlessly compatible with any standard urethane caulk gun, this auto glass sealant offers excellent adhesion without the need for surface prep. Our car seam sealer ensures quick and professional-grade gap filling.

- Versatile Application Across Vehicles: Perfect as car body filler for boats, trucks, and RVs, this automotive paintable seam sealer ensures a seamless fit on body panel and seams. Acting as an RV seam sealer, it meets diverse automotive repair needs effectively.

- Professional Results Guaranteed: Trusted by auto repair experts across the USA, our auto body seam sealer ensures high-quality, professional repairs with every use. Satisfaction guaranteed—see the difference in your repairs!

- High-Quality & Durable Repairs: Our auto seam sealer adopts high-quality urethane, no pungent smell during repairing; cured flexible to the touch, absorb door closing impact; resist heat(-49~239°F), weather & temperature change, never brittle, hardened or softened; no rework and no laborious maintenance

- Tightly Seal All Seams: The auto seam sealer adheres tightly to metal, aluminum, plastic surfaces, never peel or shrink; thick viscosity ensures completely coverage, prevent bare metal & door edge from rust, stop water, dust & wind leak in car from original seam

- Paintable & All-Weather Performance: cocomfix auto body seam sealer needs no primer, no fear of moisture and heat, instantly apply with manual or electric caulk gun; fast set and ready for road in 24 hours, also, you can use paint to change its color or polish to change its shape, until the original gap totally blends with the surrounding car body

- Safe & No Harmful Release & Interior & Exterior Use: Consider unable ventilation after car door closing, our seam sealer adheres an exclusive safe formula, won’t release any volatile gas, no VOC, protect the health of you and your family members sitting in the car

- Full Trust without Concern: If our seam sealer automotive below your expectations, we will provide an intact substitute or indemnify the original value of your order, so please get in touch with us when in need!

- Fast-Drying Automotive Seam Sealer: Specifically designed for automotive use, this sealer dries quickly, saving time on body repairs.

- Flexible & Durable Finish: Remains flexible, preventing cracks, hardening, sinking, or sagging for long-lasting, professional results.

- Easy Brush Application & OEM Match: Applies smoothly with a brush, holding perfect brush marks to replicate OEM seams.

- Excellent Adhesion & Versatile Sealing: Seals cracks, crevices, body seams, and joints with superior adhesion, ideal for lap and flange seams. This auto body seam sealer ensures a strong bond.

- Paintable in 30-60 Minutes, Light Gray: Ready for painting in under an hour, providing a seamless, light gray finish for automotive repairs.

SEOCONTENT-START

OPERATION DESCRIPTION TIME 170044A 2016-2017 Explorer 3.5L Ti-VCT: Perform Web Assessment, Obtain Repair Verification Code (RVC) And Replace The Muffler Assembly Following Procedure 2 (Do Not Use With Any Labor Operations Outside Of This Article) 0.7 Hr. MT170044 2016-2017 Explorer/Police Utility: Reseal The Body Following the Police/ Aftermarket or Retail Procedure (Do Not Use With Any Labor Operations Outside Of This Article) Actual Time WARRANTY STATUS: Eligible Under Provisions Of New Vehicle Limited Warranty Coverage And Emissions Warranty Coverage Warranty/ESP coverage limits/policies/prior approvals are not altered by a TSB. Warranty/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool. DEALER CODING BASIC PART NO. CONDITION CODE 61280B62 42

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-10 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

![Exhaust Odor in Vehicle - 2016-2017 Ford Explorer 51 [Black] Professional Automotive Seam Sealer, Paintable Quick-Set Polyurethane Auto Body Seam Sealer for Metal Surfaces of Cars, Trucks, Etc, Includes Gloves & Tip - Black RV Roof Sealant](https://m.media-amazon.com/images/I/41fApnuHD4L.jpg)

![Exhaust Odor in Vehicle - 2016-2017 Ford Explorer 53 [2-Pack] Black Polyurethane Seam Sealer Automotive Compound Kit - Durable & Flexible Auto Body Filler - Seam & Joint Compound for Bare, Primed or Painted Surfaces - Automotive Seam Sealer [Black]](https://m.media-amazon.com/images/I/4184QW8Um7L.jpg)

![Exhaust Odor in Vehicle - 2016-2017 Ford Explorer 62 [2 Pack] Polyurethane Seam Sealer Automotive Compound Kit - Durable & Flexible Auto Body Filler - Seam & Joint Compound for Bare or Painted Surfaces - Automotive Seam Sealer White - RV Roof Sealant](https://m.media-amazon.com/images/I/413vOkWzIrL.jpg)

![Exhaust Odor in Vehicle - 2016-2017 Ford Explorer 64 [2 Pack] Professional Automotive Seam Sealer, Paintable Quick-Set Polyurethane Auto Body Seam Sealer for Metal Surfaces of Cars, Trucks, Etc, Includes Gloves & Tip - White RV Roof Sealant](https://m.media-amazon.com/images/I/51BnJdNKa5L.jpg)