| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10136582

Manufacturer Communication Number: TSB18-2062

Summary

Some 2012-2014 Focus vehicles equipped with a 2.0L gasoline direct injection (GDI) engine may exhibit concerns of engine runs rough, crank no-start, loss of power, loss of engine RPM, and/or illuminated MIL with diagnostic trouble codes (DTCs) P0122, P0222, P0320, P0322, P0327, P0332, P0344, P0369, P06A7, P060D, P061C, P1336, P1674, P2111, P2112, P2127 and/or P2135. Follow the Service Procedure steps to correct the condition.

6 Affected Products

Vehicles

TECHNICAL SERVICE BULLETIN2.0L GDI – Various Drivability Concerns And/Or Illuminated Malfunction Indicator Lamp (MIL) | 18-2062

19 February 2018 |

This bulletin supersedes 15-0036. Reason for update: Incorrect or Missing Parts

Model:

2012-2014 Focus

Summary

This article supersedes TSB 15-0036 to update the Service Procedure.

Issue: Some 2012-2014 Focus vehicles equipped with a 2.0L gasoline direct injection (GDI) engine may exhibit concerns of engine runs rough, crank no-start, loss of power, loss of engine RPM, and/or illuminated MIL with diagnostic trouble codes (DTCs) P0122, P0222, P0320, P0322, P0327, P0332, P0344, P0369, P06A7, P060D, P061C, P1336, P1674, P2111, P2112, P2127 and/or P2135.

Action: Follow the Service Procedure steps to correct the condition.

Parts

| Description | Quantity | Part Number |

| Coroplast Electrical Wire Harness Tape | 1 | NAI837X |

| 22 mm (7/8 inch) Diameter Nylon Split Loom Convolute | 1 | Obtain Locally |

| 2.0 mm (0.078 inch) 14 AWG Wire | 1 per circuit | Obtain Locally |

Warranty Status: Eligible Under Provisions Of New Vehicle Limited Warranty Coverage And Emissions Warranty Coverage Warranty/ESP coverage limits/policies/prior approvals are not altered by a TSB. Warranty/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool.

Labor Times

| Description | Operation No. | Time |

| 2012-2014 Focus 2.0L GDI: Retrieve DTCs, Inspect Harness And Repair Any Damaged

Circuits (Includes Time To Repair Up To 4 Wires) Following The Service Procedure | 182062A | 1.3 |

Repair/Claim Coding

| Causal Part: | 12C508 |

| Condition Code: | 30 |

Service Procedure

- Check the vehicle build date. Was the vehicle built on or before 4-Feb-2014 with an automatic transmission or built on or before 19-Feb-2014 with a manual transmission?

(1). Yes – proceed to step 2.

(2). No – this article does not apply. Refer to Powertrain Control/Emissions Diagnosis (PC/ED) Manual for normal diagnostics.

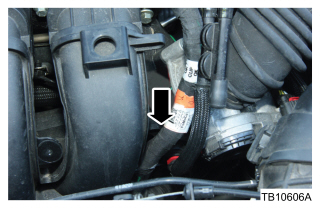

- Visually inspect the engine harness for chafing against the intake manifold, near the throttle body. It may be necessary to use a small mirror to inspect the back side of the harness where the harness may contact the intake manifold. Is a harness chafe condition present? (Figure 1)

(1). Yes – proceed to step 3.

(2). No – this article does not apply. Refer to the PC/ED Manual for normal diagnostics.

Figure 1

- Remove the harness protection and repair any damaged circuits. Refer to Cell 5 in the Wiring Diagram.

(1). When repairing damaged circuits, it is necessary to first disconnect the following electrical connectors. Refer to the Wiring Diagram for component locations.

- High-pressure Fuel Pump/Fuel Injection Pump

- Mass Airflow/Intake Air Temperature (MAF/IAT) sensor

- Evaporative Purge Valve

- Engine Coolant Temperature (ECT) sensor

- Heated Oxygen Sensors (HO2S11 and HO2S12)

- Fuel Rail Pressure (FRP) sensor

- Camshaft Position (CMP11 and CMP12) sensors

- Variable Camshaft Timing (VCT11 and VCT12) solenoids

- Coil-on-plugs (COP), all 4

(2). Remove the air cleaner assembly. Refer to Workshop Manual (WSM), Section 303-12.

(3). Remove the bolt from ground G103.

(4). With the engine harness retainers disconnected from the top of the engine, the engine harness can be lifted and moved forward to gain access to the circuits in the chafing location.

(5). Additional wire of approximately 2 mm (0.078 in.) must be added to the repaired circuits to maintain proper circuit length. Refer to the Wiring Diagram Cell 5 and use the solder method.

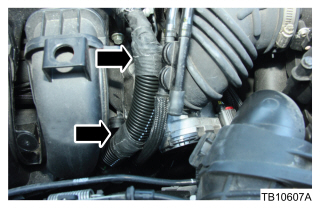

- Install protective shielding on the wire harness to prevent future circuit damage.

(1). Obtain a 15 cm (6 in.) length piece of 22 mm (7/8 in.) diameter flexible nylon split loom convolute and Coroplast tape or equivalent. Secure the convolute to the engine wire harness. Coroplast tape or equivalent must be applied in the location where the harness crosses the intake manifold near the throttle body and also to secure the convolute to the wire harness. (Figure 2)

(2). Clean and install the ground G103 bolt and tighten to 10 Nm (89 lb-in).

Figure 2

- To install, reverse the removal procedure. Refer to WSM, Section 303-12

1 Associated Document

Manufacturer Communications

18-2062

19 February 2018

https://www.nhtsa.gov/recalls?nhtsaId=10136582

MC-10136582-9999.pdf 135.555KB

Loading...

Loading...

15-0036

Loading...

Loading...

- Size: Inner diameter: 1/4"| Length: 25 Feet | Color: Black. Our wire loom is made of 100% new and high quality polyethylene

- Our split loom is split and easy to put wires in. Our split loom tubing is thick enough to provide full protection for the wires

- Operating temp (degree F.):-94 to 257 | our split wire loom is used to protect electrical wiring in industry,automotive,home & office

- Our wire loom tubing is resistance to abrasion & harmful chemicals corrosion.Good chemical stability

- Our wire protector tubing is used to wrap wires,and make cables wires neat and orderly

- Proper Size: with dimensions of approximately 1/4, 3/8, 1/2, 3/4 inch x 10 feet, our split wire protector tubing provides ample space to encase multiple wires at once while maintaining the compactness for easy management; Despite its generous length and capacity, this conduit remains lightweight to ensure high portability and installation convenience

- Long Lasting Material: manufactured from quality PE plastic, this split wire protector is engineered to keep in wide applications; This resilient material is capable of withstanding temperatures of 65 °C ( 149 degrees Fahrenheit) continuously and 90 °C ( 194 degrees Fahrenheit) for a short period, ensuring a reliable and long lasting solution for your wire management needs

- Protect Your Wires: for families with pets such as rabbits, cats, and dogs, it is also a solution to preserve pets from chewing wires, because our wire tubes are durable and wear resistant, and can efficiently manage and protect your wires, making your room look tidy and convenient for your life

- Practical Design: our split wire conduit not only provides functionality but also incorporates aesthetics with a pleasant black color; The split opening design enables easy wire insertion and removal, making the wire maintenance effortless and efficient; Encasing your wires has never looked so classy and neat

- Versatile Applications: showcasing a nice level of versatility, our plastic wire cover tubing is suitable for a wide range of industries; Regardless of whether you are in automotive, electronics, farm or agricultural, marine, recreation vehicles, telecommunications, construction, etc., this conduit will serve as an essential piece in your wire management strategy

- More High Operation Temperature Range: -40 to 257 | It is more high-quality and safer than other products with a lower operating temperature range. Great wire tubing for automotive, marine, industrial, office, home…

- High quality material and high operating range flex tubing will protect your wires from oil or heat or a chewing-like pet.

- High Quality Polyethylene Material: with newly high tech to heighten density, our wire protector tubing is thermostable and inflaming retarding!

- Protect Your Wires: resistant to abrasion, corrosion, gasoline, oil, and other harmful chemicals. This split loom tubing is perfect for indoor or outdoor wire cover.

- Easy Installation: With side-cut corrugated wire loom tubing is much easier to use. Great plastic cover for electrical wires and cables.

- Split Loom Tube

- 3/4 Inch Coil 19 mm

- 100 Foot Roll

- Inner Diameter: 1/2 Inch | Length: 25 Feet | Material: Thick & flame retardant POLYPROPYLENE (PP), raw material for better performance and safety

- Comes with a wire loom insertion tool, makes feeding wires through the split loom so much easier and quicker

- Operating temperature range: -22 °F to 221 °F, ideal for use on automotive, industrial, office and home applications

- Designed with a slit along its length, easy to add or remove cables without the need to disconnect the entire length

- Excellent abrasion, chemical and heat resistance, the wire protector tubing will protect your wires in a variety of harsh environments

- Split Loom Tube

- Color: Black

- 20 Foot Roll

- 1 Inch 25mm

- Use to protect electrical wiring in automotive, marine, hydralic applications

- Size: Inner diameter: 3/4", length: 60 feet, color: black. Our split loom is split and easy to put wires in

- High Quality Material: our wire loom 3/4 inch is made of high quality polyethylene. The automotive wire looms are safer, excellent heat resistance can be used under-hood in a car,but away from exhaust manifold

- Operating Temp: the electrical conduit temperature range -40F To 200F. Preventing and minimizing damage from electrical fires, or heating up of any cables or wires around your home

- Wide Application: our wire loom can be used for computer leads, television cables and any other electronic device in and around your home. Great wire tubing for automotive, marine, industrial, office, home etc

- Easy to Use: cut the length of the pipe to the size you want, then find the slit and put the wire in. Once the wire is insert, the slit will remain closed. This split loom tubing is perfect for indoor or outdoor wire cover

- Material: High Quality Polyethylene - Our Polyethylene Conduit Tubing is almost twice the density of our nearest competitor. Guaranteed to outlast and outperform any other Polyethylene Conduit Tubing being sold today. Flexible Ribbed Tube Design allows for a clean and easy install

- Resistant to abrasions, gasoline, oil, and other harmful chemicals

- Ideal for a wide range of applications: automotive, marine, industrial, office, home, etc.

- Operating range of -40? to 200?F (-40?C to 93?C)

- Sizes are measured by the inner diameter

- Size: Diameter: 1/4"| Length: 25 Feet | Color: Black. Our wire loom is split and easy to load wires. Once loaded, our cable sleeve will close on itself and perfect wire wrap

- Operating temp (degree F.):-103 to 257|Melt temp: 446. Our cable management sleeve is used for Hifi speaker hdmi automotive wires

- Our cord protector keeps cat from chewing cables. Our cable protector is insulated

- Our wire sleeve: UL Recognized

- Our cable organizer keeps the cords organized with no more messy cables in your home and office

- Split loom Size: Inner diameter: 1/4"| Length: 16.5 Feet | Color: Black. Our split loom is split and easy to put wires in.

- High Quality: Our wire loom is made of 100% new and high-quality polyethylene. Wire protector tubing operating temp (degree F.):-94 to 257; Can be used to protect electrical wiring in industries, automotive engine compartment wiring, home, and office.

- Protect Your Wires: Resistant to abrasion, corrosion, oil, and other harmful chemicals. Install our cord cover will prevent cable wear and prevent pets from chewing on the wires. The split loom tubing is perfect for indoor or outdoor wire cover.

- Wide Application: Idea to organize and protect power cords, entertainment system wiring, ethernet cables, wire harnesses, small hoses, and cable conduit.

- Easy To Installation: Cut the length of the pipe to the size you want, then find the slit and put the wire in.Great plastic cover for electrical wires and cables.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.