| “This site contains affiliate links for which OEMDTC may be compensated” |

| TECHNICAL SERVICE BULLETIN Body Creak/Pop Noise Over Bumps – Right Front Subframe Bolt Area – Built On Or Before 31-Jan-2016 | 18-2239 13 August 2018 |

This bulletin supersedes 16-0021. Reason for update: New Part/Procedure For Same Condition

Model:

Ford

2016 Explorer |

Summary

This article supersedes TSB 16-0021 to update the Service Procedure.

Issue: Some 2016 Explorer vehicles built on or before 31-Jan-2016 may exhibit a pop or creak noise from the right front mounting bolt of the front subframe. This condition may be due to a mispositioned weld between the barrel nut and the subframe mounting bracket.

Action: Follow the Service Procedure steps to correct the condition.

Parts

| Part Number | Description | Quantity |

| Obtain Locally | ValuGard™ Rust Inhibitor, VG-104/VG-104A | 1 |

| Obtain Locally | ValuGard™ Premium Undercoating, VG-101/VG-101A | 1 |

Warranty Status: Eligible Under Provisions Of New Vehicle Limited Warranty Coverage Warranty/ESP coverage limits/policies/prior approvals are not altered by a TSB. Warranty/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool.

Labor Times

| Description | Operation No. | Time |

| 2016 Explorer: Diagnose And Repair The Front Subframe Following The Service Procedure (Do Not Use With Any Other Labor Operations) | 182239A | 1.3 Hrs. |

Repair/Claim Coding

| Causal Part: | 16054 |

| Condition Code: | 01 |

Service Procedure

The steps below will add an additional weld to eliminate the possibility of the barrel nut creak/pop noise.

1. Attach Rotunda Wireless Chassis Ears JSP97202 or equivalent to the subframe. Does diagnosis with the chassis ears indicate the noise is originating from the right front mounting bolt of the front subframe?

(1). Yes – proceed to Step 2.

(2). No – this article does not apply. Refer to Workshop Manual (WSM), Section 100-04 for normal diagnostics.

2. Disconnect the negative battery cable. Refer to WSM, Section 414-01.

3. Remove the right front wheel and tire assembly. Refer to WSM, Section 204-04.

4. Remove the right side fender splash shield. Refer to WSM, Section 501-02.

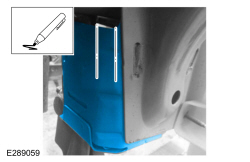

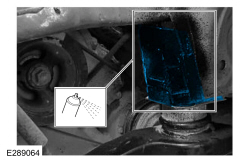

5. Locate the front subframe bolt mounting tower bracket on the right side frame member and mark 2 cut lines approximately 63 mm (2.50 in) long as shown. (Figure 1)

Figure 1

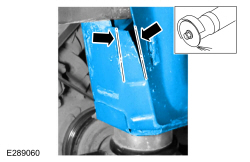

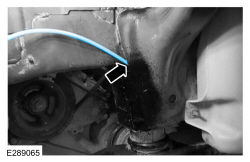

6. Using an abrasive cut off wheel, cut the bracket sheet metal along the marked lines. (Figure 2)

(1). Make sure to only cut through the outer layer.

Figure 2

7. Position the sheet metal out of the way to allow access to the barrel nut. (Figure 3)

Figure 3

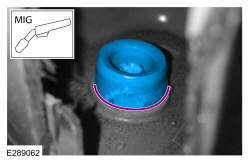

8. Using a MIG welder, weld the barrel nut to the bracket along the seam. The weld bead should span as far along the seam as possible. Refer to WSM, Section 501-25 Body Repairs – General Information > General Procedures > Welding Precautions. (Figure 4)

Figure 4

9. Position the sheet metal back to the original location.

10. Prepare the area for welding by grinding and cleaning.

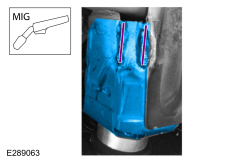

11. Using a MIG welder, weld the previously cut sheet metal to repair the bracket. (Figure 5)

Figure 5

12. Clean the welded area to prepare it for corrosion protection.

13. Apply ValuGard™ Premium Undercoating or equivalent corrosion protection to the repaired cut line area. Refer to WSM, Section 501-25. (Figure 6)

Figure 6

14. Apply ValuGard™ Rust Inhibitor or equivalent to the welded barrel nut. Refer to WSM, Section 501-25.

(1). Use an appropriate spray nozzle to access the cavity. (Figure 7)

Figure 7

15. Install the right side fender splash shield. Refer to WSM, Section 501-02.

16. Install the right front wheel and tire assembly. Refer to WSM, Section 204-04.

17. Reconnect the negative battery cable. Refer to WSM, Section 414-01.

18-2239

13 August 2018

Loading...

Loading...

- Perfect for use on bare or primed metal underbodies of cars, trucks, trailers, RVs and more

- Rubberized formula protects against corrosion and damage from water, salt and other chemicals

- Dries to the touch in 30 minutes and covers up to 10-12 sq. ft. per can

- Undercoating helps deaden sound and reduce damage to parts

- Features a wide, comfort spray tip and any-angle spray technology for easy painting even upside down

- Perfect for use on bare or primed metal underbodies of cars, trucks, trailers, RVs and more

- Professional-grade formula provides superior protection against corrosion and damage from water, salt and other chemicals

- Dries to the touch in 1 hour and covers up to 10-15 sq. ft. per can

- Undercoating helps deaden sound and reduce damage to parts

- Features a wide, comfort spray tip and any-angle spray technology for easy painting even upside down

- Easy to use spray seals and protects metal surfaces from corrosion and moisture

- Flexible, rubberized coating provides superior chemical and abrasion resistance

- Dries to touch in 1-2 hours and covers 85-175 sq. ft. per qt. with rust protection

- Apply by brush, roller or spray to repair rust problems and prevent future issues

- Creates a protective coating with no shine, flat finish on rusted or bare metal

- FRAME COATING: This special aerosol spray is both a rust prevention and rust destroyer formula rolled into one. It will not only protect your chassis from the start of rust formation and allow you to maintain a clean finish, it also eliminates the need for any future maintenance or repairs, ensuring that it will be as good as new for years to come.

- HOW TO USE: Shake the can vigorously for at least 1 minute before and occasionally during use. Insert extension tube into spray nozzle then insert extension nozzle into frame openings, bolt holes, etc.Depress spray button and apply coating while pulling the extension nozzle back from the opening. Continue in all areas you can for complete coverage.

- EASTWOOD QUALITY: Eastwood offers solutions which combines our 4,000+ unique products with the know-how to “Do The Job Right”. With an In-house product design, development and testing and a strong track record of high-quality, innovative products. Used and trusted by top builders to beginners and also provides a Lifetime Tech Support.

- SAFETY INFORMATION: Always wear eye, skin and respiratory protection when applying this product.Use in a well ventilated area away from open flame. Store spray in a cool dry place. Warning: This product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

- WARRANTY: Comes with a 90-day limited warranty and 90-day return.

- MULTI-PURPOSE UNDERCOATING may be applied to cars, truck and recreational vehicles

- SOUND DEADENING PROPERTIES help reduce road noise

- ASPHALT-BASED product is excellent for wheel wells, quarter panels, interior fenders, under the hood and more

- PROTECTS THE UNDERCARRIAGE of vehicles from rust and abrasion

- AEROSOL DISPENSER allows for easy spray-on application

- ✅ WHY CHOOSE POR-15 RUST PREVENTIVE COATING – POR-15 is the gold standard in high performance coatings. Trusted by DIY and professionals to stop rust permanently by forming an impenetrable barrier that protects a variety of surfaces from water, chemicals, salt, corrosive contaminants and everyday wear and tear. No other paint, coating, or even powder coat can match POR-15 Rust Preventive Coating when applied using the 3-Step Stop Rust System.

- ✅ CURED BY MOISTURE – The secret strength lies in the curing process. Unlike most paints that dry through evaporation, POR-15 Rust Preventive Coating dries faster when moisture is present. It has the opposite chemistry of ordinary paints. Once cured, the coating forms an indestructible, hammer tough finish.

- ✅ APPLICATION - Remove grease, oil, and other foreign substances using POR-15 water-based Cleaner Degreaser followed with POR-15 Metal Prep to etch the surface and neutralize rust. Stir POR-15 Rust Preventive Coating thoroughly, DO NOT SHAKE. Always apply thin coats, minimum of two. May be recoated or top coated when dry to the touch, typically 2 to 5 hours. Topcoat when surface will have exposure to UV light.

- ✅ WHEN DO I NEED THIS – Automotive, Farm, industrial, commercial marine, and construction industries all use POR-15 Rust Preventive Coating to protect valuable equipment against rust, abrasion, & corrosion. Our coating has excellent surface tolerance on porous surfaces, such as wood, fiberglass, concrete, bricks, and more!

- ✅ OUR SATISFACTION COMMITMENT – At POR-15 we strive to bring the ultimate in rust prevention. Known for the unbeatable 3-step stop rust system, POR-15 is trusted by DIY & Professionals. We are committed to innovation, quality control, and excellent customer service.

- FLUID FILM BLACK offer powerful corrosion protection for all metals and superior lubrication for moving parts. The long lasting thixotropic liquids and gels is aptly used in the highly corrosive marine environment and vehicle undercoating in the automotive and snow handling industries

- HOW IT WORKS. The wet barrier creeps and migrates into tight seams and into the metal chassis to provide corrosion protection from salts and brines. Protects your vehicle while restoring a rich black color to the chassis or cover existing rust

- NO SOLVENT. Formulated from specially processed wool-wax, highly refined petroleum oils and selected agents, providing a non-toxic, non-irritating, non-flammable coating for corrosion control, penetration, metal wetting and water displacement

- WIDELY USED for maintenance of locks & hinges at home, lawn & garden tools & equipment, as well as in the aviation and automobile industries. In government and commercial facilities. Equipment in fishing, gas companies, farming, salt, power and industrial plants

- Comprehensive Protection: Provides a durable, rubberized coating that safeguards vehicle undercarriages from corrosion caused by moisture, salt, and other environmental factors.

- Sound Dampening: Effectively reduces road noise by dampening vibrations, contributing to a quieter ride.

- Easy Application: The aerosol spray format ensures a uniform application without running, suitable for cars, trucks, and recreational vehicles.

- Professional Grade: Trusted by professionals for its high-quality formulation, delivering reliable performance in various conditions.

- Pack of 6: Includes six 16 oz cans, providing ample coverage for multiple vehicles or extensive projects.

- Versatile Pneumatic Application Gun: Ideal for automotive rust proofing, undercoating, chip guard, truck bed liner, and various oil, solvent, or water-based coatings.

- Precision & Texture Control: Lightweight, balanced, and precisely machined for applying different viscosity coatings and achieving various textures.

- Includes Two 22" Flexible Extension Wands: One multi-directional nozzle for hard-to-reach areas and hollow frames; one straight single-direction nozzle.

- Aluminum Body with Comfortable Grip & Air Regulator: Features a die-cast aluminum alloy body, easy-grip trigger handle for extended use, built-in air pressure regulator with gauge and a 25-ounce suction feed aluminum fluid cup.

- Designed for Professional & DIY Use: Suitable for both professional auto body shops and DIY enthusiasts looking for reliable coating application.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.