| “This site contains affiliate links for which OEMDTC may be compensated” |

| General Service Bulletin (GSB): | Module Programming |

| GSB Overview: | This General Service Bulletin will cover the proper tool usage along with programming procedures to use and tips on how to perform these procedures |

| NOTE: This information is not intended to replace or supersede any warranty, parts and service policy, Work Shop Manual (WSM) procedures or technical training or wiring diagram information. | |

This General Service Bulletin covers the following topics:

- Where to go in the Integrated Diagnostic System (IDS) Tool to Access Module Programming

- The Different Module Programming Types

- Programmable Module Installation

- Module Reprogramming

- Programmable Parameters

- As-Built

- Central Car Configuration

- Module Reprogramming/Programming Tips

- Module Programming Failures and Corrective Actions 5. Detecting Unauthorized/Non-Factory PCM Calibrations

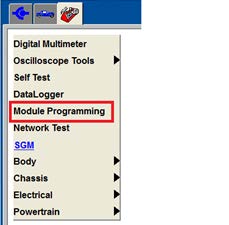

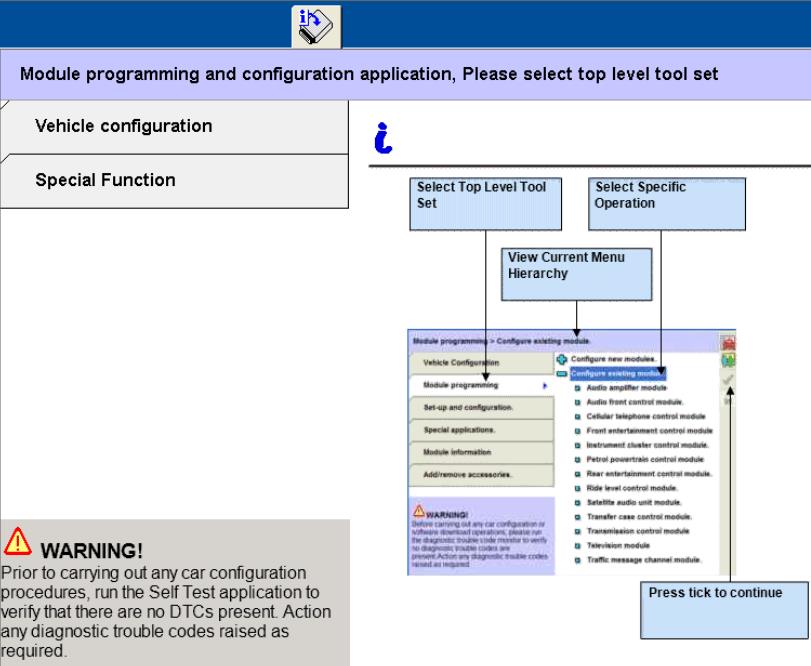

Module Programming Menu

- Module Programming Menu (figure 1) is available in the Toolbox tab after starting a session with a vehicle.

NOTE: The module programming tab is disabled when a manual vehicle session is started

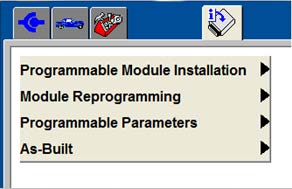

- When selecting the Module Programming Menu (figure 2) you will see 4 tabs

NOTE: Some tabs may not be present on all vehicles.

- Programmable Module Installation (PMI)

- Module Reprogramming

- Programmable Parameters

- As-Built

Figure 1

Figure 1

Programmable Module Installation (PMI)

- When replacing a module, this function ensures the correct software/calibration and configuration data are loaded onto the new module. This is required regardless of whether or not the original module is available.

- Software/calibration files are what determine how a module processes data and commands outputs. PMI downloads these files from a Ford

server, then loads the files to a new module through software download or “flash”.

server, then loads the files to a new module through software download or “flash”. - The configuration data is vehicle specific, and provides reference points for the software about a vehicle’s build level or option content – including customer preference settings. Configuration data is “inhaled” or copied from the original module and “exhaled” or written to the new module.

Note: PCMs support flash and configuration, but other modules may support only one or the other. PMI will automatically determine what is necessary.

- When running PMI, start the IDS session with the original module installed in the vehicle. Vehicle ID will inhale the original software/calibration part numbers, and configuration data.

- PMI will compare the original part numbers to the newly installed module to determine if it is the correct part, and to determine if it requires a software flash (it may already have the appropriate software).

- The configuration data will be stored and later exhaled to the new module. This ensures customer preference (daytime running lights, belt minder, etc) and dynamic data (oil minder, transmission characterization, etc) will carryover to the new module.

- Starting a session and running PMI when the original module does not communicate, (or is not available) creates the need for IDS to pull part numbers and configuration data from As-built. This will occur automatically during PMI and if not, you will be referred to the As-Built menu. See page 7 for more info on As-built.

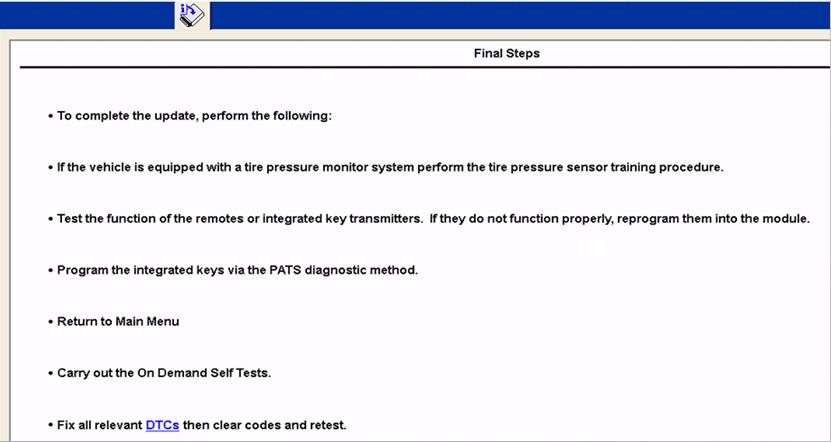

After the calibration and configuration have been loaded and checked, the Final Steps screen will appear giving additional steps required to complete the installation process. Refer to the workshop manual for complete installation procedures required for the module being replaced.

Module Reprogramming

- Module Reprogramming will update the software/calibration of a module when directed by a FSA, TSB, SSM or Workshop Manual procedure. In rare cases it may also update configuration data inside the module.

- Module Reprogramming will look at the current software levels within the module (captured during Vehicle ID) and compare this information with the IDS database. If there is an update, it will be displayed on the IDS screen.

NOTE: Module Reprogramming should not be attempted unless directed by a Technical Service Bulletin(TSB) , Special Service Message(SSM), Field Service Action(FSA) or the Workshop Manual.

As-Built

- As-Built data is a record of the module part numbers and configuration data created at the assembly plant for each vehicle. This is done as a backup resource in the event that PMI must be performed without data from the original module.

- Note: As-Built data may not be available or required for all modules

- PTS will display only the raw As-built configuration data(the data found on PTS), but the part numbers are also included when IDS downloads the As-built file for the VIN.

- The As-built menu option lets you decide whether you want to utilize part numbers or configuration data from the As-built file. This will overwrite the data gathered (if any) for the selected module during Vehicle ID.

- In the figure below, answer Yes to obtain part numbers, and answer No to restore factory configuration data.

Central Car Configuration

- This programming jointly programs the Instrument Panel Cluster (IPC) and the Body Control Module (BCM). This is required after either module is replaced. Refer to workshop manual removal and installation procedures.

- Provides another means for changing customer preference parameters. Ex: Remote Start, DRLs, Climate Control parameters( if applicable to vehicle). Refer to workshop manual section 418-01 a for list of changeable parameters on the vehicle.

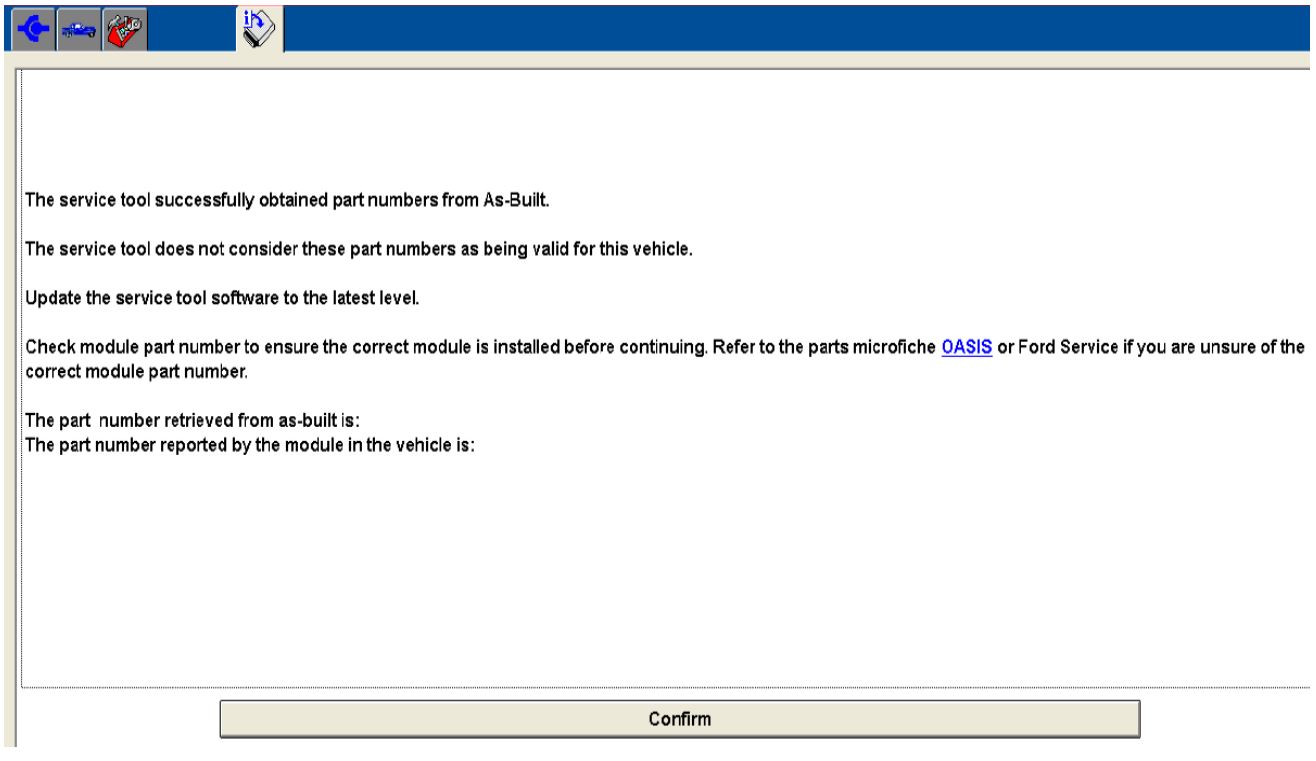

Part Number Error Message During Programming

During Programmable Module Installation(PMI) and during Module Reprogramming, the IDS will read the part number of the module installed and verify it’s correct for this model/year. If IDS does not recognize the part as being correct for the model/year, programming will end with an error message.

Corrective Actions;

- Verify a new IDS session started for the VIN you are working on

- Verify your IDS is at the latest available level

- Verify the part number of the module installed is correct

- Verify the Powertrain Control Module(PCM) has not been tuned or modified.

- The IDS session is largely based on the PCM software and calibration strategies.

- Perform as-built programming on the module that failed and when asked the question in the below image, answer it ‘yes’. When done, return to the programming procedure that failed.

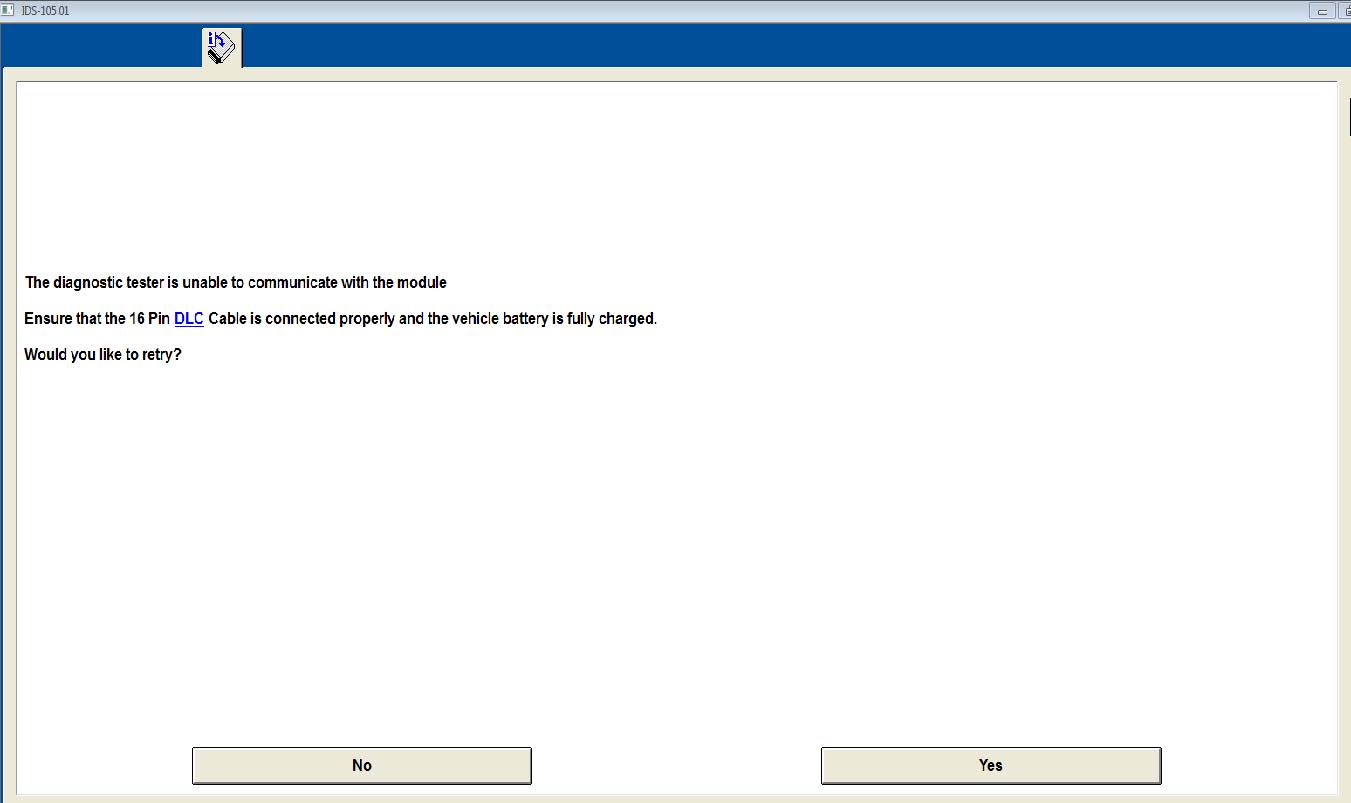

VCM Communication and Module Communication Error Messages

The IDS will verify the module you are trying to program is communicating numerous times during programming. If you can’t talk to the module you are programming over the network, you can’t give it data during programming.

Corrective Actions;

- Verify the 12 volt vehicle battery is fully charged

- Verify the correct Vehicle Communication Module(VCM) is being used for the vehicle

- Attempt disconnecting and reconnecting the VCM to the vehicle and computer . Try using a different VCM

- Verify that the Data Link Connector(DLC) has power to pin 16 and ground at pins 4 and 5.

- Verify that the module is passing a network test

- Refer to workshop manual section 418-00 > Diagnosis and Testing and any published TSBS, SSMs, or GSBs for communication concerns.

Note: Replacement modules should be capable of passing a network test before programming.

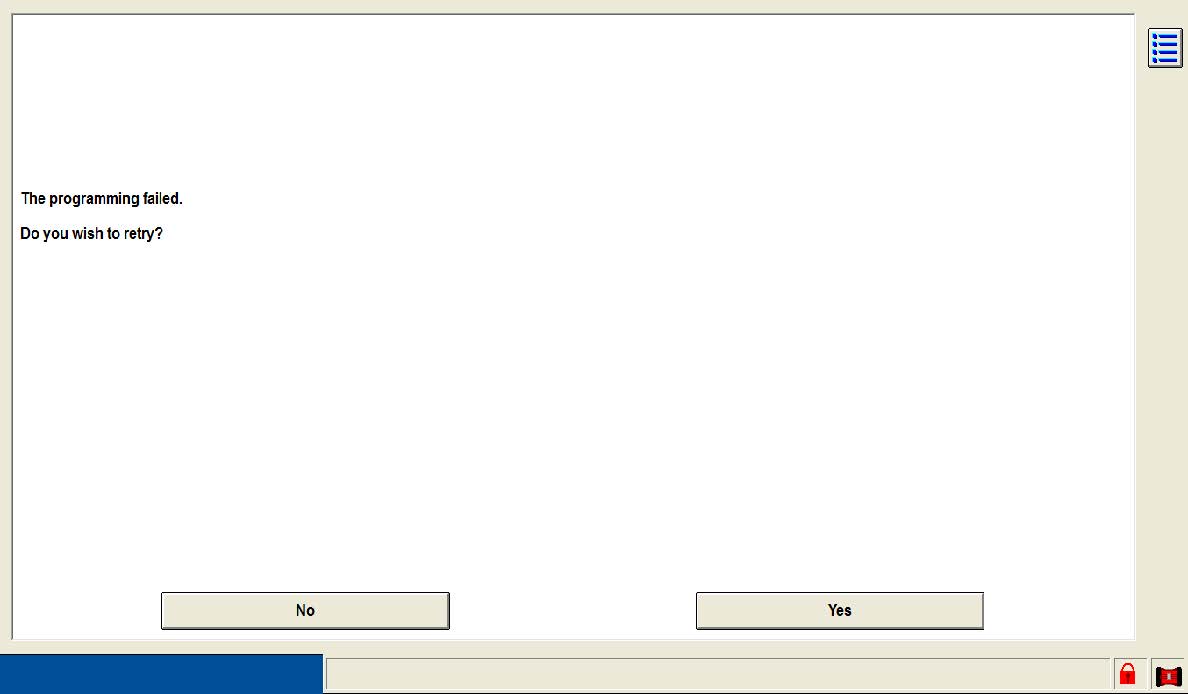

Module Configuration Has Failed Error Message

Module Configuration Has Failed Error Message

This Error Message may be encountered during PMI, As-Built programming or during Module Reprogramming. This error message is encountered when the is trying to load the Configuration Data(As-Built found on PTS) to the module.

Correct Actions:

- Verify the ignition is on. The ignition must be on for the module to complete this step in programming

- If the ignition has timed out and shut off on a push button start vehicle, cycle the ignition off, then on, and then click ‘yes’ to retry. This error message will generally provide the option to retry

- Verify the module is capable of passing a network test. If the module isn’t communicating, it won’t accept the data the IDS is sending to it

- Verify that the battery voltage is within typical operating range and that the battery charger is properly installed on the vehicle(should be installed with negative cable of charger to chassis ground, not on the battery negative post)

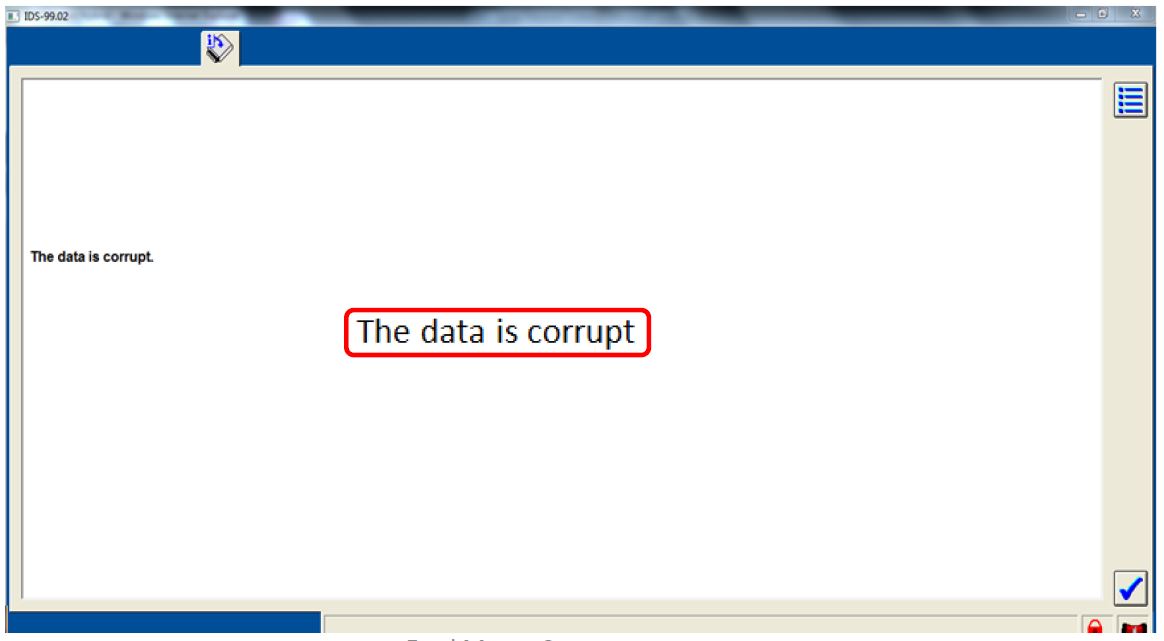

As-Built “Data Corrupt”

- This message is displayed when the IDS has either not found the data or, the data does not match the vehicle session.

- Verify that a brand new IDS session was started on the vehicle. Verify the VIN displayed is correct on the vehicle confirmation screen and was correct in the beginning steps of the module programming process being performed.

NOTE: If the data is missing from PTS > OASIS > As-Built, refer to page 16

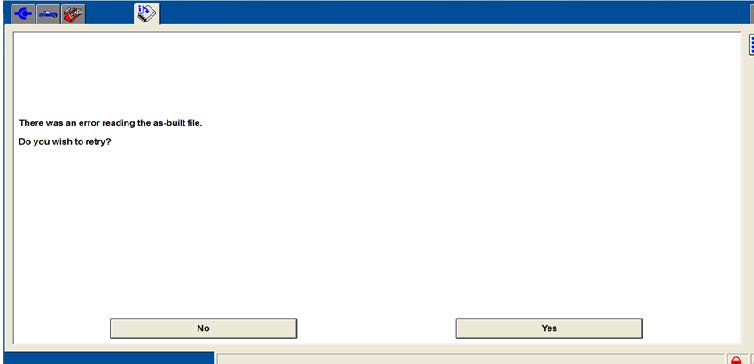

How to obtain Missing As-Built Data from PTS

- Begin the Programmable Module Installation(PMI) on the module missing data

- When the error below is encountered, answer this question ‘no’

- This will force IDS to request the data

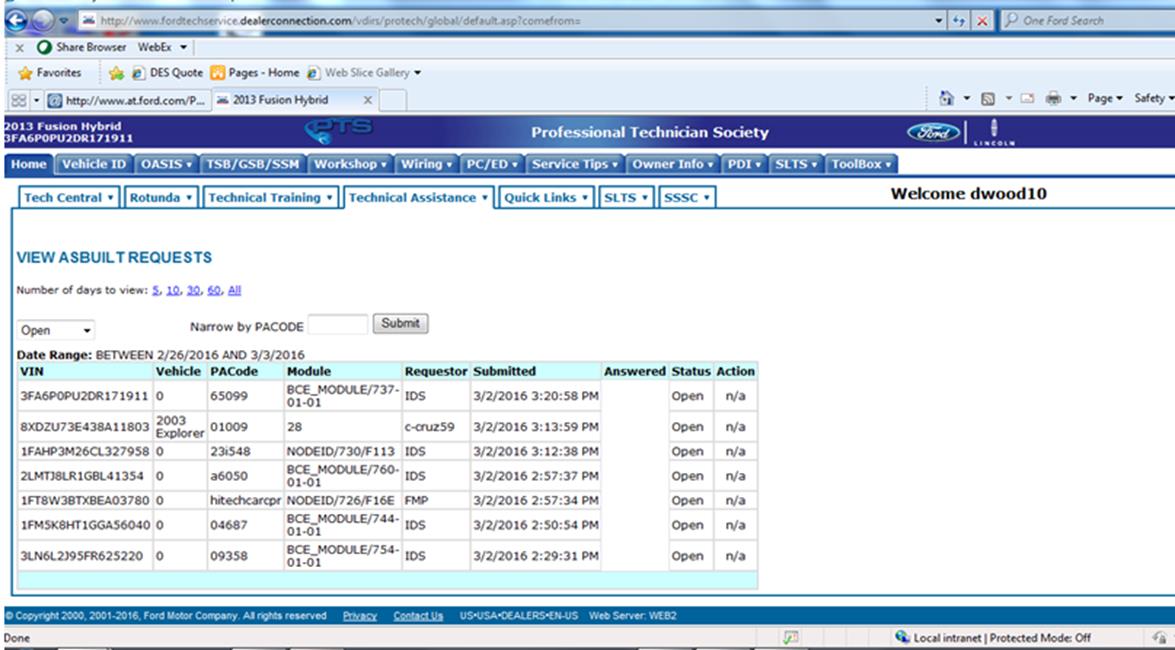

- Navigate to PTS > Technical Assistance > As-Built Request Status and search for the VIN. ** this screen is shown below

- The requester will be listed as ‘IDS’ and the “Status” will change to ‘Answered’ when the data is available. Once answered, you can use the IDS that programming failed on and attempt the PMI one more time as normal.

Module Programming and Reprogramming Service Tips

Use the following tips to help ensure programming completes without errors:

- Ensure that the session is created (Key ON Engine OFF (KOEO))

- Connect vehicle to a battery charger set on the optimal charge setting

- Connect the IDS tool (computer) to a power source

- Inspect the VCM and cables for any damage and ensure cables remain connected throughout programming

- A hardwired internet connection is strongly recommended

- Turn off all accessories (radio, heated/cooled seats, headlamps, HVAC, close all doors, etc.)

- For Plug-In EVs, disconnect any external EVSEs/HV Charge Cords from the charge port.

- Follow all on-screen instructions carefully, especially any key cycle movements the IDS directs you to perform. Allow the startup/power down routines to complete

- Disable Microsoft Windows sleep mode, screensaver, hibernation modes

- On many vehicles, a validation will be performed of the configuration of other modules on the network by the module being reprogrammed. An overall loss of communication with a module may prevent a module reprogramming action from completing. The cause of the communication concern must be corrected before reprogramming will complete.

NOTE: Disconnect any aftermarket items (remote start, alarm, power inverter, insurance devices, etc.)

Recovering a PCM/SJB When Programming has Resulted in a Blank Module

IMPORTANT: Never Delete the Original Session

- Obtain the original IDS used when the programming error occurred during Module Reprogramming or Programmable Module Installation (PMI).

- Disconnect the VCM from the IDS and then the DLC.

- Reconnect VCM to the IDS and then the DLC. The VCM icon should appear in the corner of the IDS screen. If the VCM icon does not appear, troubleshoot the IDS-to-VCM connection.

- Attempt to start a new IDS session for the vehicle, if the IDS can read the VIN it will default into the failed programming session. If it cannot read the VIN, locate the original vehicle session used when programming failed. In most cases this would be the last session used. If you cannot locate the original vehicle session, use the session created on the date the programming failed. Using an IDS with the latest release available, sessions with failed programming will be highlighted in RED.

NOTE: If the original session is not in the previous list, click the Recycling Bin icon in the lower right of the Previous Sessions screen. This will load any deleted session, double click on the session to restore.

- Once the session is loaded, the failed process should resume automatically.

- If programming does not resume automatically, proceed to the Module Programming menu and select the previously attempted process (PMI or Module Reprogramming).

- Follow all on-screen instructions to complete the programming process. Near the end of programming, IDS will prompt you to select certain parameters. It is important to make a selection for ALL parameters listed, even if the correct selection is highlighted you need to click that selection before clicking the Tick mark to complete the configuration.

- The last screen on IDS may list additional steps required to complete the programming process. Ensure all applicable steps are performed in the order listed on the screen.

Detecting Unauthorized/Non-Factory PCM Calibrations

Unauthorized/non-factory PCM calibrations may not be detectable using standard tools or diagnostic equipment. Customer acknowledgement is the only conclusive method to verify an unauthorized PCM calibration has been utilized. Two methods often misused to verify the presence of an unauthorized PCM calibration are:

The PCM Filename of the software file in the PCM.

Due to the design of unauthorized calibration equipment (Aftermarket Tuners) and the inherent possibility that this equipment will utilize a factory PCM Filename, the PCM Filename cannot be used to verify the presence of an unauthorized calibration. For example, the aftermarket calibration may have the same filename as a valid Ford Motor Company Calibration.

Motor Company Calibration.

The Ignition Counter (IGN_CTR) located in Mode 9

This data displays the number of ignition key cycles since the most recent PCM calibration update. The PCM calibration may be updated at a dealership or a 3rd party facility with an IDS or other scan tool causing the Ignition Counter to reset. The accuracy of this value cannot be determined as this value resets with any calibration update.

To ensure an accurate repair and prevent repeat failures, follow any applicable publications in OASIS. If no applicable service publications are available refer to the following:

- Determine extent of damage and complete the repair per the Warranty and Policy Manual and published Workshop Manual procedures.

- After the repair is completed, install the factory calibration in the PCM (use the procedure shown on pg. 10).

- After the PCM calibration is restored, refer the customer to the Warranty and Policy Manual regarding the vehicle warranty and risks of unauthorized calibrations.

Returning PCM calibration to the factory setting

- Start a normal IDS session. If a previous session is present, select None of the Above.

- Select “No” when verifying the information on the “Vehicle Specification” screen.

- Enter the Tear Tag into the IDS to identify the vehicle.

- NOTE: The Tear Tag is located under the As-Built screen from the OASIS tab on PTS.

- There will be a second “Vehicle Specification” screen. Verify information and select “Yes”

- When the session is started, “Module Programming” should automatically begin. If it does not, select Programmable Module Installation (PMI) from the IDS menu and select PCM.

This procedure will only install the latest factory calibration and will not verify if an unauthorized calibration was installed. Following the repair, attach the PCM Filename, Ignition Counter and any DTCs to the repair order for documentation.

G0000150

Loading...

Loading...

G0000095

Loading...

Loading...

Reprogramming

Service Information & Reprogramming

Module Reprogramming

| Diagnostic Software | Interface Device | Complete Vehicle Diagnostics | Module Programming | ||

| 1996-2017 Model Year |

2018-Present Model Year |

1996-2017 Model Year |

2018-Present Model Year |

||

| IDS/FDRS | VCM, VCM II , VCMM , VCMM |

X | X | X | X |

| FJDS/FDRS | Compatible J2534 Devices (Including VCM II  and VCMM) and VCMM) |

X | X | X | |

Detailed system requirements, installation, and support information for each product is located under the diagnostics tool support tab for each product.

Integrated Diagnostic Software (IDS) / Ford Diagnosis & Repair System (FDRS)

Diagnosis & Repair System (FDRS)

For use with VCM I, VCM II , VMM and VCMM hardware devices only. The complete factory Ford

, VMM and VCMM hardware devices only. The complete factory Ford Motor Company vehicle diagnostic tool that provides complete dealership level vehicle diagnostic coverage for all 1996 to present Ford

Motor Company vehicle diagnostic tool that provides complete dealership level vehicle diagnostic coverage for all 1996 to present Ford , Lincoln

, Lincoln and Mercury

and Mercury vehicles. The IDS software includes time based access to the IDS software, software updates and calibration files.

vehicles. The IDS software includes time based access to the IDS software, software updates and calibration files.

Ford J2534 Diagnostic Software (FJDS) / Ford

J2534 Diagnostic Software (FJDS) / Ford Diagnosis & Repair System (FDRS)

Diagnosis & Repair System (FDRS)

For use with compatible J2534 hardware devices. FJDS software provides Ford Module Programming functionality that covers 1996 to present Ford , Lincoln

, Lincoln and Mercury

and Mercury module reprogramming functions, plus complete dealership level vehicle diagnostic software for all 2018 to present Ford

module reprogramming functions, plus complete dealership level vehicle diagnostic software for all 2018 to present Ford and Lincoln

and Lincoln vehicles. The FJDS software license includes time based access to the FJDS software, software updates and calibration files.

vehicles. The FJDS software license includes time based access to the FJDS software, software updates and calibration files.

| CarDAQ-Plus 3 All Makes J2534 Reprogramming Tool | |

| CarDAQ-Plus 2 Diagnostic Code Reader and J2534 Programming Tool | |

| CarDAQ-Plus | |

| CarDAQ-M | |

| VSI J2534 ECU Reprogrammer | |

Latest Calibration Information

Module Build Data (As-Built)

Use VIN to obtain As-Built data

- J2534 Pass-Thru Programmer: TOPDON RLink J2534 is an advanced diagnostic and reprogramming tool that support all J2534 protocols, as well as D-PDU, CAN-FD and DoIP, ensuring compatibility with a wide range of modern vehicles. It offers extensive versatility with support for over 17 major automotive brands, including Chrysler, Ford

, GM, Nissan, Toyota, Honda, Subaru, Land Rover/Jaguar, Volvo, Wuling, Volkswagen, Mercedes-Benz, and BMW, and so on, enjoy dealership-level functions at your fingertips

, GM, Nissan, Toyota, Honda, Subaru, Land Rover/Jaguar, Volvo, Wuling, Volkswagen, Mercedes-Benz, and BMW, and so on, enjoy dealership-level functions at your fingertips - All-in-One OEM Diagnostics: This J2534 ECU programming tool elevates your automotive repair capabilities to new heights by delivering complete OEM diagnosis. Boasting comprehensive full-system diagnostics, intuitive repair guides, advanced ECU programming and coding, common reset services, a vast library of repair information and more, this all-in-one solution empowers technicians to effortlessly tackle complex vehicle issues with ease

- Proven Performance You Can Trust: Backed by over 10000 real vehicle tests and benefit from a wealth of practical experience, this OEM reprogramming tool guarantees stable and exceptional performance. Supported by TOPDON's dedicated technical experts with in-depth knowledge of both auto repair and J2534 Pass-Thru programming, the RLink J2534 provides prompt and professional assistance, ensuring a smooth setup and reliable compatibility

- Integrated Excellence, Always Up-to-Date: Featuring the exclusive RLink Platform to provide a streamlined experience with one-click driver installation and management, ensuring flawless integration with your OE software, maintaining the original performance quality. The built-in operation guide makes mastering OE software quick and easy, so you can get started right away. Plus, with lifetime free updates, your diagnostics will stay current with the latest drivers and innovations

- Efficiency Meets Versatility: Engineered to support three CAN channels simultaneously - CAN FD and CAN-CC included, giving you the edge in fast troubleshooting. To perfectly synchronized with the OE software, please diagnose with active subscriptions and make sure your computer system is running a compatible 64-bit Windows version (7, 8, 10 or later) to fully leverage the power of RLink J2534. *We don't provide extra OE software

- 【J2534 PROTOCOL WITH SMARTLINKC】 LAUNCH X431 PRO3S+ ELITE scan tool with newly upgraded smartlinkC V2.0. The SmartLinkC is a communication interface supporting J2534 specifications. Of course, it also can be used as a J2534 PassThru device, working together with the PC installed with the OEM diagnostic software to perform the J2534 protocol.J2534 protocol is the only solution for problems ranging from driveability and loss of power to poor fuel economy.

- 【INTELLIGENT TOPOLOGY MAP TO FASTER FULL SYSTEMS DIAGNOSIS】 X431 PRO3S+ELITE bidirectional scan tool with new-added intuitive topology mapping. Harnesses intuitive topology mapping for comprehensive visualization of the vehicle all system. It shows all available control units in different colors, the numbers of system, the scanned system, and the scan results, bringing maximum convenience & superfast speed for you to do swift diagnosis & high-level repairs.

- 【TOP HARDWARE CONFIGURATION, UPGRADED OF LAUNCH X431 PRO3S+】 LAUNCH X431 PRO3S+ELITE diagnostic scanner possess with Android 10.0 OS; CPU 4-Core Processor, 2.0 GHz. Greatly increased the speed of running multiple task. 2.4GHz/5GHz; 6300mAh/7.6V stronger battery capacity; 10.1 Inch Touchscreen with 8MP camera; AUTO VIN; 4GB+64GB storage memory; 20X faster transmission rate, save more vehicle documents and customer data; Supports 25+ Software Languages, such as EN, DE, FR, SP nd JP and so on.

- 【3000+ ACTIVE TEST/BI-DIRECTIONAL CONTROL LAUNCH SCANNER】 LAUNCH X431 PRO3S+ELITE HD automotive scanner is a cost-effective bidirectional scanner that deserves owned by every repairing DIYers and mechanics. You can easily send command signal at fingertips from the scanner to various module actuators to test component integrity and functionality in minutes or even seconds to tell if replacement or repair is needed.

- 【COMPLETE 60+ HOT RESETS, CALIBRATION, INITIALIZATION, RELEARN】 LAUNCH X431 PRO3S+ELITE SmartLinkC escaner automotriz professional enjoys 60+ special service, such as Oil Reset, ABS brake bleed, EPB, SAS, BMS, Suspension, Injector reset, Power Balance, Turbo Calibration, VGT, Transmission Adaption, Throttle Adaptation, matching and etc. rigorous on-site testing has been performed to ensure 100% availability.

- 🌐【Works with Autel Elite II Elite MS908 MS908S Pro II MS908CV II MK908P MK908 Pro II】Autel J2534 work with these tools to program ECUs on specific BM.W/ BE.NZ for specific functions. ★★NOTE: J2534 CANNOT directly work with these single devices. After you received the J2534, you HAVE TO send us both the S/N(12 digits) of your scanner MS908S(etc.) and J2534. So, technically, Autel engineers can help you bind J2534 with your devices. If need any supports, contact us via: 🚘auteldirect @ outlook. com🚘.

- 🌐【SAE J2534-1 & J2534-2 Standards】Autel MaxiFlash Elite J2534 is a fully compliant SAE J2534-1 & SAE J2534-2 (March 2006) device, which performs standard PassThru J2534 functionality: Compatible with for Toyota Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. Autel MaxiFlash J2534 is also specially designed to provide users with P-C communication and ECU reprogramming capabilities on any modern vehicle diagnostic bus, reliability and flexibility.

- 🌐【High-speed Transmission Speed】Autel MaxiFlash Elite Reprogramming Device J2534 supports simultaneous communication definition in J2534-1, running 3 protocols at the same time, which greatly improves reprogramming and diagnostic speed. Embedded with the ARM9 Dual-core processor (clocked up to 500MHz), which further boosts the communicating speed to save more times and win more business.

- 🌐【Multiple Devices Connected with P-C】Autel MaxiFlash Elite J2534 also supports multiple device connections to the P-C, which can operate diagnostic and reprogramming functions on more than one vehicle at the same time. Autel MaxiFlash Elite J2534 built-in wireless and data storage, which can update via Internet. It also ensures quickly reprogramming even the newest controllers.

- 🌐【Extensive Compatibility】Autel MaxiFlash J2534 is compatible with Toyota Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. To check compatibility, please contact 🚘auteldirect @ outlook . com🚘 directly for satisfaction-guaranteed support!

- ALL OF THE J2534 PROTOCOLS - This single unit has all of the protocols you need for your OEM J2534 reprogramming and diagnostics including the latest in DoIP and CanFD

- J2534 TECHNICAL SUPPORT - FREE for the life of the tool. Staffed by technicians who understand vehicle repair and J2534 Pass‑thru

- TOOLBOX WITH OEM APPLICATION DESCRIPTIONS - educational video tutorials and real-time news – Giving you the confidence and up-to-date knowledge to get the job done

- J2534 v05.00 API - The newest version of J2534 to give you the latest in pass-thru technology

- FUTURE PROOF WITH 4 CAN CHANNELS - Going beyond the 3 required by select Chrysler/FCA models, CarDAQ-Plus 3 also provides a 4th to meet the needs of future OEM applications

- CUSTOM-DESIGNED FOR USE WITH FORSCAN: Works with all FORScan compatible vehicles and is recommended by the FORScan Team

- DEALERSHIP-LEVEL DIAGNOSTICS: OBDLink EX supports all Ford protocols, modules, and advanced features of FORScan

- ELECTRONIC SWITCH allows FORScan to access all CAN buses simultaneously and enables advanced functions not possible with “toggle switch” adapters

- MAXIMUM THROUGHPUT -- up to 20 times faster than “toggle switch” adapters

- ROCK-SOLID CONNECTION avoids data corruption and dropped packets

- [J2534 COMPLIANT] - The Mastertech II is a J2534-1 and J2534-2 compliant VCI for OEM reprogramming and diagnostic applications

- [FULLY VALIDATED BY TOP 6 OEMS] - Mastertech II has been fully validated to operate with the top 6 OEM reprogramming applications: GM, Ford, FCA, Nissan/Infinity, Honda/Acura, and Toyota/Lexus

- [PRE-CONFIGURED] - The pre-configured wireless and wired connections make it quick and easy to connect to a vehicle from your PC (requires PC compliant with OE specifications and software)

- [RIGHT TO REPAIR] - Supports 'Right to Repair' (R2R) initiatives

- [COMPREHENSIVE KIT] - Kit includes: VCI, WiFi adapters (wireless PC to VCI), J1962 Cable (connect to vehicle), USB cable (connect to PC for firmware updates and setup), and Quick Start Guide

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.