| “This site contains affiliate links for which OEMDTC may be compensated” |

August 12, 2022 NHTSA CAMPAIGN NUMBER: 22V623000

Damaged Driveshaft May Fracture

A fractured driveshaft can cause a loss of drive power, or a loss of vehicle control if the driveshaft contacts the ground. Additionally, unintended movement could occur while parked if the parking brake is not engaged. Any of these scenarios increases the risk of a crash.

NHTSA Campaign Number: 22V623

Manufacturer Ford Motor Company

Motor Company

Components POWER TRAIN, STRUCTURE

Potential Number of Units Affected 58,203

Summary

Ford Motor Company (Ford

Motor Company (Ford ) is recalling certain 2021-2022 F-150 vehicles. Underbody heat and noise insulators may loosen and contact the aluminum driveshaft, which could damage the driveshaft and cause it to fracture.

) is recalling certain 2021-2022 F-150 vehicles. Underbody heat and noise insulators may loosen and contact the aluminum driveshaft, which could damage the driveshaft and cause it to fracture.

Remedy

Dealers will inspect and repair the driveshaft, as necessary, and properly attach the underbody insulators, free of charge. Owner notification letters were mailed September 1, 2022. Owners may contact Ford customer service at 1-866-436-7332. Ford

customer service at 1-866-436-7332. Ford ’s number for this recall is 22S53.

’s number for this recall is 22S53.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.nhtsa.gov.

Check if your Vehicle has a Recall

August 15, 2022

NEW VEHICLE DEMONSTRATION / DELIVERY HOLD –

Safety Recall 22S53

Certain 2021-2022 Model Year F-150 Vehicles Equipped with Crew Cab, 145” Wheelbase,

4×4, One-Piece Aluminum Driveshaft, and MFAL BHDAA (Less Sound Insulation Packs)*

Loose/Sagging Underbody Insulators

*This corresponds to Equipment Packages XL & XLT 301A and below, and Tremor 400A.

AFFECTED VEHICLES

| Vehicle | Model Year | Assembly Plant | Build Dates |

| F-150 | 2021-2022 | Dearborn | January 22, 2020 through November 2, 2021 |

| F-150 | 2021-2022 | Kansas City | June 1, 2020 through October 15, 2021 |

The eleventh VIN position is the assembly plant code.

- F – Dearborn Assembly (Dearborn, Michigan) = DTP

- K – Kansas City Assembly (Claycomo, Missouri) = KCAP

Affected vehicles are identified in OASIS and FSA VIN Lists.

REASON FOR THIS SAFETY RECALL

In some of the affected vehicles, underbody insulators may have been installed in error. If installed, the underbody insulators may loosen and contact the aluminum driveshaft, resulting in marking or scoring of the driveshaft. Over time, the aluminum driveshaft may fracture, which can result in loss of motive power while driving, unintended vehicle movement while the vehicle is in park if the parking brake is not applied, and secondary damage to surrounding components. A fractured driveshaft may also contact the ground which may cause loss of control of the vehicle while driving. A fractured driveshaft increases the risk of injury or crash.

SERVICE ACTION

Before demonstrating or delivering any new in-stock vehicles involved in this recall, dealers will inspect if either the driver or passenger-side underbody insulator(s) are present. If either underbody insulator is present, the dealer will secure the underbody insulator(s) and inspect the driveshaft, fuel vapor lines and electrical connectors for damage and repair as required. This service must be performed on all affected vehicles at no charge to the vehicle owner.

OWNER NOTIFICATION MAILING SCHEDULE

Owner letters are expected to be mailed the week of September 5, 2022. Dealers should repair any affected vehicles that arrive at their dealerships, whether or not the customer has received a letter.

PLEASE NOTE:

Federal law requires dealers to complete this recall service before a new vehicle is delivered to the buyer or lessee. Violation of this requirement by a dealer could result in a civil penalty of up to $21,000 per vehicle. Correct all vehicles in your new vehicle inventory before delivery.

SOLD VEHICLES

- Ford

has not issued instructions to stop selling/delivering or driving used vehicles under this safety recall. Owners should contact their dealer for an appointment to have their vehicles remedied as soon as practicable. Owners can continue to safely drive their vehicles.

has not issued instructions to stop selling/delivering or driving used vehicles under this safety recall. Owners should contact their dealer for an appointment to have their vehicles remedied as soon as practicable. Owners can continue to safely drive their vehicles. - Immediately contact any of your affected customers whose vehicles are not on your VIN list but are identified in OASIS. Give the customer a copy of the Owner Notification Letter (when available) and schedule a service date.

- Correct other affected vehicles identified in OASIS which are brought to your dealership.

- Dealers are to prioritize repairs of customer vehicles over repairs of new and used vehicle inventory.

STOCK VEHICLES

- Correct all affected units in your new vehicle inventory before delivery.

- Use OASIS to identify any affected vehicles in your used vehicle inventory.

DEALER-OPERATED RENTAL VEHICLES

The Fixing America’s Surface Transportation (FAST) Act law effective June 2016 prohibits a rental company from selling, renting or leasing vehicles subject to a safety or compliance recall. Please consult your legal counsel for legal advice.

TITLE BRANDED / SALVAGED VEHICLES

Affected title branded and salvaged vehicles are eligible for this recall.

OWNER REFUNDS

- This safety recall must still be performed, even if the owner has paid for a previous repair. Claiming a refund will not close the recall on the vehicle.

- Ford

Motor Company is offering a refund for owner-paid repairs covered by this recall if the repair was performed prior to the date indicated in the reimbursement plan, which is posted with this bulletin. Owners are directed to seek reimbursement through authorized dealers or, at their option, directly through Ford

Motor Company is offering a refund for owner-paid repairs covered by this recall if the repair was performed prior to the date indicated in the reimbursement plan, which is posted with this bulletin. Owners are directed to seek reimbursement through authorized dealers or, at their option, directly through Ford Motor Company at P.O. Box 6251, Dearborn, MI 48121-6251.

Motor Company at P.O. Box 6251, Dearborn, MI 48121-6251. - Dealers are also pre-approved to refund owner-paid emergency repairs that were performed away from an authorized servicing dealer after the end date specified in the reimbursement plan. Non-covered repairs, or those judged by Ford

to be excessive, will not be reimbursed.

to be excessive, will not be reimbursed. - Refunds will only be provided for the cost associated with driveshaft replacement.

RENTAL VEHICLES

- PASS INSPECTION: Vehicles that pass the applicable driveshaft, fuel systems, and electrical inspections are NOT affected and are not approved for rental vehicles. Refer to the 22S53 technical instructions for additional information.

- FAIL INSPECTION: Vehicles that fail either the applicable driveshaft, fuel systems, or electrical inspections

-

- Parts are NOT available:

-

-

- Driveshaft, vapor line, or pigtail is on back-order.

-

-

-

- PARTS ESCALATION PROCESS (Vehicle Off Road) process has been followed and COPIS ticket with VOR flagged has been submitted.

-

-

-

- Prior approval is required from the SSSC, submit contact type long-term rental for consideration and approval if appropriate.

-

- A ten-digit prior-approval code is required from the SSSC for rental vehicles, a new approval code is required from SSSC every 30 days.

- If rental vehicles are needed beyond December 31, 2022, dealers will have to contact SSSC for an extension.

- Approval for all rental vehicles for this program will end on December 31, 2022.

- Follow Extended Service Plan (ESP) guidelines for dollar amounts. Prior approval is required from the SSSC.

PARTS REQUIREMENTS / ORDERING INFORMATION SSSC Web Contact Site:

Parts are not yet available to repair all vehicles. Until parts are available to repair all vehicles, dealers may only order parts and repair vehicles, which are customer-owned vehicles currently in the dealership and unsold vehicles with a signed sales contract.

Driveshaft – Only replace the driveshaft if marks are present per the technical instructions.

| Part Number | Description | Order Quantity |

| *-4602-* | Driveshaft (part number varies by vehicle – use Ford ECat to identify the specific part number by VIN) ECat to identify the specific part number by VIN) | As Required |

NOTE: The Driveshaft flange to pinion flange bolt part number N800594-S100 has been removed from the parts list for this program, and may be reused. Refer to the 22S53 Technical Information on updated instructions for thread cleaning and application of thread adhesive.

| Rivet Part Number’s | Description | Order Quantity | ||||

Any of the following part numbers may be used:

| Rivets

(Pack of 4, 5 needed per DTP vehicles, 2 needed per KCAP vehicles) NOTE: Part numbers ending in S900C are packages of 100 |

2 DTP | ||||

| 1 KCAP |

Aluminum Driveshaft, and MFAL BHDAA (Less Sound Insulation Packs) Loose/Sagging Underbody Insulators

| Driveshaft Replacement | XG-1-E1 | Motorcraft® Premium Long-Life Grease | 1 |

| Driveshaft Replacement | XT-10QLVC | MERCON® LV Automatic Transmission Fluid (12 per case, 1 Quart bottle required) | 1 |

Obtain the parts below locally:

| Part Number | Description | Quantity Needed |

| Obtain Locally | Zinc coated steel or Aluminum washers, ¼ inch ID, 2-inch OD, Thickness 2mm (Max). | 5 needed per DTP Vehicle Claim as Misc. Other |

| 2 needed per KCAP Vehicle Claim as Misc. Other | ||

| Obtain Locally | LOCTITE 243 Blue Medium Strength Threadlocker or equivalent – Specification WSK-M2G349-A7 | 1 tube needed per vehicle Claim as Misc. Other |

CERTAIN 2021-2022 MODEL YEAR F-150 VEHICLES EQUIPPED WITH A CREW CAB, 145″ WHEELBASE, 4X4, ONE-PIECE ALUMINUM DRIVESHAFT, AND MFAL BHDAA (LESS SOUND INSULATION PACKS) – LOOSE/SAGGING UNDERBODY INSULATORS

SERVICE PROCEDURE

GAS ENGINES – VEHICLES MANUFACTURED AT DEARBORN TRUCK ASSEMBLY PLANT

Table Of Contents

Underbody Insulator Presence – 1

Check for DTCs – 3

Inspection – 3

Driveshaft – 3

Zones 1, 3 and 4 – 3

Zone 2 – 5

Driver Side Insulator – 7

Vapor Line – 7

Securing Underbody Insulators – 9

Appendix A – Acceptable Photos – 13

Underbody Insulator Presence

1. With the vehicle in NEUTRAL, position it on a hoist. Please follow Workshop Manual (WSM) procedures in Section 100-02.

2. Are either one or both of the underbody insulators present on the vehicle? See Figure 1.

Yes – Proceed to step 3.

No – This recall is complete.

NOTE: The driver side insulator is located directly above the fuel tank.

NOTE: The passenger side insulator is located directly above the exhaust.

NOTE: Insulators are highlighted for illustration purposes only.

Review the video link below before starting this repair procedure:

Materials List

| Ruler/Scale/Straight Edge | 13 mm (1/2 in) Drill Stop | Small Brush |

| Drill | 6.7 mm (17/64 in) Drill Bit | Marker |

| 1/4″ Rivet Gun | 5.1 mm (13/64 in) Drill Bit – Rivet W719880-S417 | Tape |

NOTE: A ¼” air over hydraulic rivet gun was used for the service trials for this program, however a pneumatic rivet gun or a manual rivet gun may also be used. However, it may not be possible to access and properly secure the rivets into the floor pan using a manual rivet gun. It is important to always confirm the rivet is properly secured to the floor pan of the vehicle.

Check for DTCs

3. Using the Ford Diagnostic and Repair System (FDRS), check the Powertrain Control Module (PCM) for DTCs. Are either of the following DTC’s present in the PCM, P0442 and/or P0456?

Diagnostic and Repair System (FDRS), check the Powertrain Control Module (PCM) for DTCs. Are either of the following DTC’s present in the PCM, P0442 and/or P0456?

Yes – Please follow Workshop Manual (WSM) procedures for pinpoint test HX in Section 303-13, then proceed to step 4.

No – Proceed to step 4.

Inspection

4. Remove the driveshaft. Please follow WSM procedures in Section 205-01.

NOTE: Do NOT discard the driveshaft flange to pinion flange bolts.

Zones 1, 3 and 4

5. Inspect Zones 1, 3 and 4 of the rear driveshaft for any marks caused by the front and/or rear edges of the passenger side insulator. Are there any marks present in Zones 1, 3 or 4? See Figure 2.

Yes – Proceed to step 6.

No – Proceed to step 8.

6. What is the current odometer reading?

> 2,500 miles – Proceed to step 7.

< 2,500 miles – Proceed to step 8.

7. Place a straight edge along the driveshaft over the wear mark and attempt to fit a 0.018in (0.45mm) feeler gauge between the flat edge and the wear mark. Can the feeler gauge fit between the straight edge and anywhere along the wear mark? See Figures 3 and 4.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the driveshaft with the feeler gauge fitting between the straight edge and wear mark. Once approved, rear driveshaft replacement will be required, but do not install at this time. Proceed to step 10.

No – Passes inspection. Proceed to step 8.

Zone 2

8. Inspect Zone 2 (transition from larger tube diameter to smaller diameter section) of the driveshaft tube for any marks caused by the front edge of the passenger side insulator. Are there any marks present? See Figure 5.

Yes – Does not pass inspection. Proceed to step 9.

No – Passes inspection. Driveshaft may be reused. Proceed to step 10.

9. Inspect the marks found on Zone 2. Is the aluminum tube surface grain pattern worn off, completely smooth, or have an appearance of necking? See Figures 6 through 9.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the driveshaft with the grain pattern worn off. Be sure to show a clear image of the grain pattern missing. Once approved, rear driveshaft replacement will be required, but do not install at this time. Proceed to step 10.

No – Passes inspection. Driveshaft may be reused. Proceed to step 10.

Driver Side Insulator

10. Inspect the driver side insulator for any edges hanging down or touching the fuel tank. Is the insulator hanging down or touching the fuel tank? See Figure 10.

Yes – Does not pass inspection. Proceed to step 11.

No – Passes inspection. Proceed to step 13.

11. Remove the fuel tank to gain access to the vapor line. Please follow WSM procedures in Section 310-01.

12. Inspect the vapor line for any damage caused by the driver side insulator. Is there any damage to the line? See Figures 11 through 13.

Yes – Does not pass inspection. Replace the damaged line. Please follow WSM procedures in Section 310-01, then proceed to step 13.

No – Passes inspection. Proceed to step 13.

Securing Underbody Insulators

NOTE: Perform steps 13 through 22 ONLY on the side(s) where the insulator(s) are present.

13. Measure and mark the four locations on the passenger side insulator and mark the one location on the driver side insulator. See Figures 14 and 15.

14. Use the 5.1 mm (13/64 in) drill bit for rivet part number W719880-S417 or the 6.7mm (17/64 in) drill bit for all other rivet part numbers to drill a hole through the insulator and into the floor. See Figure 16.

NOTE: Use the 13 mm (1/2 in) drill stop to ensure you do not drill through the carpet.

15. Repeat step 14 for the remaining four marked locations.

16. Using a small brush, apply a layer of the anti-corrosion coating to the edges of the newly drilled holes.

17. Install the washer onto the rivet. See Figure 17.

NOTE: All approved listed rivet part numbers may not look identical to the photos in the technical instructions.

18. Apply a thick layer of seam sealer to the rivet, and the backside of the washer. See Figure 18.

19. Using a 1/4″ rivet gun, install the rivet and washer to the drilled hole. See Figure 19.

NOTE: To ensure the rivet is properly secured, apply as much force to the rivet gun as possible.

20. Attempt to move the washer/rivet to confirm it is properly secured.

21. Using a small brush, apply a layer of the anti-corrosion coating to the washer and rivet.

22. Repeat steps 17-21 for the remaining four drilled holes.

23. Install the fuel tank if it was removed in the inspection. Please follow WSM procedures in Section 310-01.

24. Using an air blow gun, remove any debris from threaded holes in axle flange. See Figure 20.

NOTE: Make sure that the mating faces are clean and free of foreign material.

25. Inspect the original driveshaft flange to pinion flange bolts for rust in the threads and replace if rusted or damaged. Clean threads of the original driveshaft flange to pinion flange bolts with a wire brush and coat the threads with LOCTITE 243 Blue Medium Strength Threadlocker or equivalent. See Figure 21.

26. Install the driveshaft. Please follow WSM procedures in Section 205-01.

CERTAIN 2021-2022 MODEL YEAR F-150 VEHICLES EQUIPPED WITH A CREW CAB, 145″ WHEELBASE, 4X4, ONE-PIECE ALUMINUM DRIVESHAFT, AND MFAL BHDAA (LESS SOUND INSULATION PACKS) – LOOSE/SAGGING UNDERBODY INSULATORS

SERVICE PROCEDURE

DIESEL ENGINES

Table Of Contents

Underbody Insulator Presence – 1

Inspection – 3

Driveshaft – 3

Zones 1, 3 and 4 – 3

Zone 2 – 5

Securing Underbody Insulators – 7

Appendix A – Acceptable Photos – 11

Underbody Insulator Presence

1. With the vehicle in NEUTRAL, position it on a hoist. Please follow Workshop Manual (WSM) procedures in Section 100-02.

2. Are either one or both of the underbody insulators present on the vehicle? See Figure 1.

Yes – Proceed to step 3.

No – This recall is complete.

NOTE: The driver side insulator is located directly above the fuel tank.

NOTE: The passenger side insulator is located directly above the exhaust.

NOTE: Insulators are highlighted for illustration purposes only.

Review the video link below before starting this repair procedure:

Materials List

| Ruler/Scale/Straight Edge | 13 mm (1/2 in) Drill Stop | Small Brush |

| Drill | 6.7 mm (17/64 in) Drill Bit | Marker |

| 1/4″ Rivet Gun | 5.1 mm (13/64 in) Drill Bit – Rivet W719880-S417 | Tape |

NOTE: A ¼” air over hydraulic rivet gun was used for the service trials for this program, however a pneumatic rivet gun or a manual rivet gun may also be used. However, it may not be possible to access and properly secure the rivets into the floor pan using a manual rivet gun. It is important to always confirm the rivet is properly secured to the floor pan of the vehicle.

Inspection

3. Remove the driveshaft. Please follow WSM procedures in Section 205-01.

NOTE: Do NOT discard the driveshaft flange to pinion flange bolts.

Zones 1, 3 and 4

4. Inspect Zones 1, 3 and 4 of the rear driveshaft for any marks caused by the front and/or rear edges of the passenger side insulator. Are there any marks present in Zones 1, 3 or 4? See Figure 2.

Yes – Proceed to step 5.

No – Proceed to step 7.

5. What is the current odometer reading?

> 2,500 miles – Proceed to step 6.

< 2,500 miles – Proceed to step 7.

6. Place a straight edge along the driveshaft over the wear mark and attempt to fit a 0.018in (0.45mm) feeler gauge between the flat edge and the wear mark. Can the feeler gauge fit between the straight edge and anywhere along the wear mark? See Figures 3 and 4.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the driveshaft with the feeler gauge fitting between the straight edge and wear mark. Once approved, rear driveshaft replacement will be required, but do not install at this time. Proceed to step 9.

No – Passes inspection. Proceed to step 7.

Zone 2

7. Inspect Zone 2 (transition from larger tube diameter to smaller diameter section) of the driveshaft tube for any marks caused by the front edge of the passenger side insulator. Are there any marks present? See Figure 5.

Yes – Does not pass inspection. Proceed to step 8.

No – Passes inspection. Driveshaft may be reused. Proceed to step 9.

8. Inspect the marks found on Zone 2. Is the aluminum tube surface grain pattern worn off, completely smooth, or have an appearance of necking? See Figures 6 through 9.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the driveshaft with the grain pattern worn off. Be sure to show a clear image of the grain pattern missing. Once approved, rear driveshaft replacement will be required, but do not install at this time. Proceed to step 9.

No – Passes inspection. Driveshaft may be reused. Proceed to step 9.

Securing Underbody Insulators

NOTE: Perform steps 9 through 18 ONLY on the side(s) where the insulator(s) are present.

9. Measure and mark the four locations on the passenger side insulator and mark the one location on the driver side insulator. See Figures 10 and 11.

10. Use the 5.1 mm (13/64 in) drill bit for rivet part number W719880-S417 or the 6.7mm (17/64 in) drill bit for all other rivet part numbers to drill a hole through the insulator and into the floor. See Figure 12.

NOTE: Use the 13 mm (1/2 in) drill stop to ensure you do not drill through the carpet.

11. Repeat step 10 for the remaining four marked locations.

12. Using a small brush, apply a layer of the anti-corrosion coating to the edges of the newly drilled holes.

13. Install the washer onto the rivet. See Figure 13.

NOTE: All approved listed rivet part numbers may not look identical to the photos in the technical instructions.

14. Apply a thick layer of seam sealer to the rivet, and the backside of the washer. See Figure 14.

15. Using a 1/4″ rivet gun, install the rivet and washer to the drilled hole. See Figure 15.

NOTE: To ensure the rivet is properly secured, apply as much force to the rivet gun as possible.

16. Attempt to move the washer/rivet to confirm it is properly secured.

17. Using a small brush, apply a layer of the anti-corrosion coating to the washer and rivet.

18. Repeat steps 13-17 for the remaining four drilled holes.

19. Using an air blow gun, remove any debris from threaded holes in axle flange. See Figure 16.

NOTE: Make sure that the mating faces are clean and free of foreign material.

20. Inspect the original driveshaft flange to pinion flange bolts for rust in the threads and replace if rusted or damaged. Clean threads of the original driveshaft flange to pinion flange bolts with a wire brush and coat the threads with LOCTITE 243 Blue Medium Strength Threadlocker or equivalent. See Figure 17.

21. Install the driveshaft. Please follow WSM procedures in Section 205-01.

CERTAIN 2021-2022 MODEL YEAR F-150 VEHICLES EQUIPPED WITH A CREW CAB, 145″ WHEELBASE, 4X4, ONE-PIECE ALUMINUM DRIVESHAFT, AND MFAL BHDAA (LESS SOUND INSULATION PACKS) – LOOSE/SAGGING UNDERBODY INSULATORS

SERVICE PROCEDURE

HYBRID ENGINES

Table Of Contents

Underbody Insulator Presence – 1

Inspection – 3

Driveshaft – 3

Zones 1, 3 and 4 – 3

Zone 2 – 5

ECT Sensor Connectors – 7

Remove Passenger Side Insulator – 8

Clean Sheet Metal Surface – 8

Secure Driver Side Insulator – 9

Appendix A – Acceptable Photos – 13

Underbody Insulator Presence

1. With the vehicle in NEUTRAL, position it on a hoist. Please follow Workshop Manual (WSM) procedures in Section 100-02.

2. Are either one or both of the underbody insulators present on the vehicle? See Figure 1.

Yes – Proceed to step 3.

No – This recall is complete.

NOTE: The driver side insulator is located directly above the fuel tank.

NOTE: The passenger side insulator is located directly above the exhaust.

NOTE: Insulators are highlighted for illustration purposes only.

Review the video link below before starting this repair procedure:

Materials List

| Ruler/Scale/Straight Edge | 13 mm (1/2 in) Drill Stop | Small Brush |

| Drill | 6.7 mm (17/64 in) Drill Bit | Marker |

| 1/4″ Rivet Gun | 5.1 mm (13/64 in) Drill Bit – Rivet W719880-S417 | Tape |

NOTE: A ¼” air over hydraulic rivet gun was used for the service trials for this program, however a pneumatic rivet gun or a manual rivet gun may also be used. However, it may not be possible to access and properly secure the rivets into the floor pan using a manual rivet gun. It is important to always confirm the rivet is properly secured to the floor pan of the vehicle.

Inspection

3. Remove the driveshaft. Please follow WSM procedures in Section 205-01.

NOTE: Do NOT discard the driveshaft flange to pinion flange bolts.

Zones 1, 3 and 4

4. Inspect Zones 1, 3 and 4 of the rear driveshaft for any marks caused by the front and/or rear edges of the passenger side insulator. Are there any marks present in Zones 1, 3 or 4? See Figure 2.

Yes – Proceed to step 5.

No – Proceed to step 7.

5. What is the current odometer reading?

> 2,500 miles – Proceed to step 6.

< 2,500 miles – Proceed to step 7.

6. Place a straight edge along the driveshaft over the wear mark and attempt to fit a 0.018in (0.45mm) feeler gauge between the flat edge and the wear mark. Can the feeler gauge fit between the straight edge and anywhere along the wear mark? See Figures 3 and 4.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the driveshaft with the feeler gauge fitting between the straight edge and wear mark. Once approved, rear driveshaft replacement will be required, but do not install at this time. Proceed to step 9.

No – Passes inspection. Proceed to step 7.

Zone 2

7. Inspect Zone 2 (transition from larger tube diameter to smaller diameter section) of the driveshaft tube for any marks caused by the front edge of the passenger side insulator. Are there any marks present? See Figure 5.

Yes – Does not pass inspection. Proceed to step 8.

No – Passes inspection. Driveshaft may be reused. Proceed to step 9.

8. Inspect the marks found on Zone 2. Is the aluminum tube surface grain pattern worn off, completely smooth, or have an appearance of necking? See Figures 6 through 9.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the driveshaft with the grain pattern worn off. Be sure to show a clear image of the grain pattern missing. Once approved, rear driveshaft replacement will be required, but do not install at this time. Proceed to step 9.

No – Passes inspection. Driveshaft may be reused. Proceed to step 9.

9. Inspect the front Engine Coolant Temperature (ECT) sensor connectors for any damage caused by the passenger side insulator. Is there any damage? See Figure 10.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the damage for proper technical instructions and part numbers, then proceed to step 10.

No – Proceed to step 10.

10. Is the passenger side insulator present on the vehicle?

Yes – Proceed to step 11.

No – Proceed to step 14.

Remove Passenger Side Insulator

11. Carefully remove and discard the passenger side insulator from the underside of the pickup bed. See Figure 11.

NOTE: Do NOT use metal scrapers, wire brushes, power sanding or grinding discs, or any abrasive means to clean surfaces. These tools cause scratches and gouges which make leak paths.

Clean Sheet Metal Surface

12. Using both hands and/or a plastic scraper, remove as much of the remaining substrate material as possible. See Figure 12.

13. Using Mineral Spirits/Goo-Gone/3M Adhesive Remover/Brake Cleaner and lint-free rags or equivalent, clean the sheet metal surface.

Secure Driver Side Insulator

14 Measure and mark the one location on the driver side insulator. See Figures 13 and 14.

15. Use the 5.1 mm (13/64 in) drill bit for rivet part number W719880-S417 or the 6.7mm (17/64 in) drill bit for all other rivet part numbers to drill a hole through the insulator and into the floor. See Figure 15.

NOTE: Use the 13mm (1/2 in) drill stop to ensure you do not drill through the carpet.

16. Using a small brush, apply a layer of the anti-corrosion coating to the edges of the newly drilled hole.

17. Install the washer onto the rivet. See Figure 16.

NOTE: All approved listed rivet part numbers may not look identical to the photos in the technical instructions.

18. Apply a thick layer of seam sealer to the rivet, and the backside of the washer. See Figure 17.

19. Using a 1/4″ rivet gun, install the rivet and washer to the drilled hole. See Figure 18.

NOTE: To ensure the rivet is properly secured, apply as much force to the rivet gun as possible.

20. Attempt to move the washer/rivet to confirm it is properly secured.

21. Using a small brush, apply a layer of the anti-corrosion coating to the washer and rivet.

22. Using an air blow gun, remove any debris from threaded holes in axle flange. See Figure 19.

NOTE: Make sure that the mating faces are clean and free of foreign material.

23. Inspect the original driveshaft flange to pinion flange bolts for rust in the threads and replace if rusted or damaged. Clean threads of the original driveshaft flange to pinion flange bolts with a wire brush and coat the threads with LOCTITE 243 Blue Medium Strength Threadlocker or equivalent. See Figure 20.

24. Install the driveshaft. Please follow WSM procedures in Section 205-01.

CERTAIN 2021-2022 MODEL YEAR F-150 VEHICLES EQUIPPED WITH A CREW CAB, 145″ WHEELBASE, 4X4, ONE-PIECE ALUMINUM DRIVESHAFT, AND MFAL BHDAA (LESS SOUND INSULATION PACKS) – LOOSE/SAGGING UNDERBODY INSULATORS

SERVICE PROCEDURE

GAS ENGINES – VEHICLES MANUFACTURED AT KANSAS CITY TRUCK ASSEMBLY PLANT

Table Of Contents

Underbody Insulator Presence – 1

Check for DTCs – 3

Inspection – 3

Driveshaft – 3

Zones 1, 3 and 4 – 3

Zone 2 – 5

Secure Passenger Side Insulator – 7

Appendix A – Acceptable Photos – 11

Underbody Insulator Presence

1. With the vehicle in NEUTRAL, position it on a hoist. Please follow Workshop Manual (WSM)

procedures in Section 100-02.

2. Is the passenger side underbody insulator present on the vehicle? See Figure 1.

Yes – Proceed to step 3.

No – This recall is complete.

NOTE: If ONLY the driver side insulator is present, no action is required.

NOTE: The driver side insulator is located directly above the fuel tank.

NOTE: The passenger side insulator is located directly above the exhaust.

NOTE: Insulators are highlighted for illustration purposes only.

Review the video link below before starting this repair procedure:

Materials List

| Ruler/Scale/Straight Edge | 13 mm (1/2 in) Drill Stop | Small Brush |

| Drill | 6.7 mm (17/64 in) Drill Bit | Marker |

| 1/4″ Rivet Gun | 5.1 mm (13/64 in) Drill Bit – Rivet W719880-S417 | Tape |

NOTE: A ¼” air over hydraulic rivet gun was used for the service trials for this program, however a pneumatic rivet gun or a manual rivet gun may also be used. However, it may not be possible to access and properly secure the rivets into the floor pan using a manual rivet gun. It is important to always confirm the rivet is properly secured to the floor pan of the vehicle.

Check for DTCs

3. Using the Ford Diagnostic and Repair System (FDRS), check the Powertrain Control Module (PCM) for DTCs. Are either of the following DTC’s present in the PCM, P0442 and/or P0456?

Diagnostic and Repair System (FDRS), check the Powertrain Control Module (PCM) for DTCs. Are either of the following DTC’s present in the PCM, P0442 and/or P0456?

Yes – Please follow Workshop Manual (WSM) procedures for pinpoint test HX in Section 303-13, then proceed to step 4.

No – Proceed to step 4.

Inspection

4. Remove the driveshaft. Please follow WSM procedures in Section 205-01.

NOTE: Do NOT discard the driveshaft flange to pinion flange bolts.

Zones 1, 3 and 4

5. Inspect Zones 1, 3 and 4 of the rear driveshaft for any marks caused by the front and/or rear edges of the passenger side insulator. Are there any marks present in Zones 1, 3 or 4? See Figure 2.

Yes – Proceed to step 6.

No – Proceed to step 8.

6. What is the current odometer reading?

> 2,500 miles – Proceed to step 7.

< 2,500 miles – Proceed to step 8.

7. Place a straight edge along the driveshaft over the wear mark and attempt to fit a 0.018in (0.45mm) feeler gauge between the flat edge and the wear mark. Can the feeler gauge fit between the straight edge and anywhere along the wear mark? See Figures 3 and 4.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the driveshaft with the feeler gauge fitting between the straight edge and wear mark. Once approved, rear driveshaft replacement will be required, but do not install at this time. Proceed to step 10.

No – Passes inspection. Proceed to step 8.

Zone 2

8. Inspect Zone 2 (transition from larger tube diameter to smaller diameter section) of the driveshaft tube for any marks caused by the front edge of the passenger side insulator. Are there any marks present? See Figure 5.

Yes – Does not pass inspection. Proceed to step 9.

No – Passes inspection. Driveshaft may be reused. Proceed to step 10.

9. Inspect the marks found on Zone 2. Is the aluminum tube surface grain pattern worn off, completely smooth, or have an appearance of necking? See Figures 6 through 9.

Yes – Does not pass inspection. Contact the SSSC and provide a picture of the driveshaft with the grain pattern worn off. Be sure to show a clear image of the grain pattern missing. Once approved, rear driveshaft replacement will be required, but do not install at this time. Proceed to step 10.

No – Passes inspection. Driveshaft may be reused. Proceed to step 10.

Secure Passenger Side Insulator

10. Measure and mark the two locations on the passenger side insulator. See Figure 10.

11. Use the 5.1 mm (13/64 in) drill bit for rivet part number W719880-S417 or the 6.7mm (17/64 in) drill bit for all other rivet part numbers to drill a hole through the insulator and into the floor. See Figure 11.

NOTE: Use the 13 mm (1/2 in) drill stop to ensure you do not drill through the carpet.

12. Repeat step 11 for the second marked location.

13. Using a small brush, apply a layer of the anti-corrosion coating to the edges of the newly drilled holes.

14. Install the washer onto the rivet. See Figure 12.

NOTE: All approved listed rivet part numbers may not look identical to the photos in the technical instructions.

15. Apply a thick layer of seam sealer to the rivet, and the backside of the washer. See Figure 13.

16. Using a 1/4″ rivet gun, install the rivet and washer to the drilled hole. See Figure 14.

NOTE: To ensure the rivet is properly secured, apply as much force to the rivet gun as possible.

17. Attempt to move the washer/rivet to confirm it is properly secured.

18. Using a small brush, apply a layer of the anti-corrosion coating to the washer and rivet.

19. Repeat steps 14-18 for the second drilled hole.

20. Using an air blow gun, remove any debris from threaded holes in axle flange. See Figure 15.

NOTE: Make sure that the mating faces are clean and free of foreign material.

21. Inspect the original driveshaft flange to pinion flange bolts for rust in the threads and replace if rusted or damaged. Clean threads of the original driveshaft flange to pinion flange bolts with a wire brush and coat the threads with LOCTITE 243 Blue Medium Strength Threadlocker or equivalent. See Figure 16.

22. Install the driveshaft. Please follow WSM procedures in Section 205-01.

Chronology :

May 2022

On May 26, 2022, Ford ’s Critical Concern Review Group (CCRG) initiated an investigation into reports of aluminum driveshaft fracture on F-150 Crew Cab units that were not included in Ford

’s Critical Concern Review Group (CCRG) initiated an investigation into reports of aluminum driveshaft fracture on F-150 Crew Cab units that were not included in Ford Field Service Action (FSA) 21S56 (NHTSA Campaign Number 21V-986). The prior safety recall was approved in December 2021 to address potential aluminum driveshaft fracture resulting from underbody insulator contact on units designed and built with underbody insulators.

Field Service Action (FSA) 21S56 (NHTSA Campaign Number 21V-986). The prior safety recall was approved in December 2021 to address potential aluminum driveshaft fracture resulting from underbody insulator contact on units designed and built with underbody insulators.

June – July 2022

The CCRG investigation found that underbody insulators were installed in error on certain F-150 Crew Cab vehicles that were neither designed nor intended to be built with underbody insulators. The CCRG team reviewed records from the assembly plant and product designs to understand how vehicles could be manufactured with the unintended underbody insulators. The underbody insulators, which were installed in error, may experience the same issue of inadequate adhesion to the vehicle underbody as was addressed by FSA 21S56. This can result in loosening and sagging of the insulators, which may then contact the driveshaft.

Over time, contact of the sagging underbody insulator with the rotating aluminum driveshaft may result in material reduction and fracture of the aluminum driveshaft.

As of August 3, 2022, the team is aware of four (4) warranty reports in the United States for fractured aluminum driveshafts due to apparent underbody insulator contact on vehicles not intended to be equipped with the underbody insulators. The reports were received on November 10, 2021, May 12, 2022, May 24, 2022, and June 1, 2022.

On August 5, 2022, Ford’s Field Review Committee reviewed the concern and approved a field action.

Ford is not aware of any reports of accident or injury related to this condition.

2 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

| FORD | F-150 | 2021-2022 |

9 Associated Documents

Recall Acknowledgement

RCAK-22V623-6975.pdf 645.308KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Dealer Bulletin re NEW VEHICLE DEMONSTRATION / DELIVERY HOLD – Safety Recall 22S53 Certain 2021-2022 Model Year F-150 Vehicles Equipped with Crew Cab, 145” Wheelbase, 4×4, One-Piece Aluminum Driveshaft, and MFAL BHDAA (Less Sound Insulation Packs)* Loose/Sagging Underbody Insulators

RCMN-22V623-8744.pdf 6137.286KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-22V623-2762.PDF 216.02KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Dealer Bulletin re NEW VEHICLE DEMONSTRATION / DELIVERY HOLD – Safety Recall 22S53 Certain 2021-2022 Model Year F-150 Vehicles Equipped with Crew Cab, 145” Wheelbase, 4×4, One-Piece Aluminum Driveshaft, and MFAL BHDAA (Less Sound Insulation Packs)* Loose/Sagging Underbody Insulators

RCMN-22V623-0847.pdf 11207.15KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-22V623-8611.pdf 54.356KB

Loading...

Loading...

Recall Quarterly Report #1, 2022-3

RCLQRT-22V623-3911.PDF 211.133KB

Loading...

Loading...

ISSUED Renotification Notice

RCRN-22V623-2488.pdf 544.583KB

Loading...

Loading...

Recall Quarterly Report #2, 2022-4

RCLQRT-22V623-2937.PDF 211.238KB

Loading...

Loading...

Recall Quarterly Report #3, 2023-1

RCLQRT-22V623-6689.PDF 211.328KB

Loading...

Loading...

Latest Recalls Documents

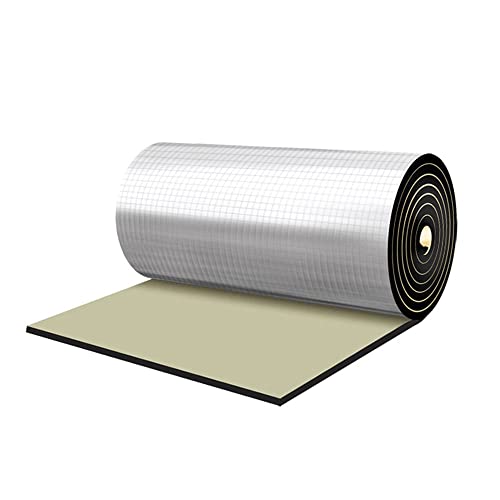

- Reflective Foam Core w/ Self Adhesive Car Heat Insulation Mat- Aluminum Foil Car Heat Shield Insulation Mat can reflective engine,header,exhaust heat and effectively blocks 97% of the suns radiant heat transfer reducing air conditioning energy consumption.

- 1/4inch (5-6mm) Nominal Thickness Heavy Duty Strong Sound Deadener Performance - Closed Cell foam Car Noise deadening proof insulation Mat excellent sound absorption reduces wind noise,road noise,engine noise etc improving driving comfort.

- Good Vibration Resistant Reduce noise- Automotive Sound Proof Heat Insulation Materials suitable for various car models can also reduce car's vibrating and rattling extending the life of the parts in the car.

- Waterproof and Weatherproof / Sound and Heat Insulation / Puncture, Crush, and Heat Resistant (ASTM Class 1 Class A Fire Heat Rated)

- Sound deadening material size: Nominal thickness 394 mils; Total coverage area of 10.76 sq.feet; Nominal sheet Size 40x40 inches. The thicker the material the more effective insulation you get! working Temperature Range: -40°F ~ 300°F

- Heat Insulation and Vibration Deadener: Effectively blocks 98% of radiant heat transfer. Sound deadening mat is a very versatile insulation material with excellent thermal barrier properties that will block engine, exhaust, & summer heat, ensuring your vehicle stays cooler in the summer and warmer in the winter, making your ride more pleasant!

- Automotive self-adhesive insulation is a waterproof lightweight thermal deadener with a highly compressible closed-cell foam formulation, it absolutely doesn’t absorb moisture and has no odor

- The sound dampening mat can be applied to external partitions, firewalls, hoods, engine compartments, engine compartments, trunks, wheel arches, body panels, load floors, and internal partitions under the seat floor.

- The sound dampening material comes in handy size sheets which make it easier in terms of the cutting and installation process and it’s flexible which makes it easy to install with or without a roller.

- Sound deadening material size: Nominal thickness 394 mils; Total coverage area of 6.5 sqft; Nominal sheet Size 40x24 inches. working Temperature Range: -40°F ~ 300°F

- Heat Insulation and Vibration Deadener: Effectively blocks 98% of radiant heat transfer. Sound deadening mat is a very versatile insulation material with excellent thermal barrier properties that will block engine, exhaust, & summer heat, ensuring your vehicle stays cooler in the summer and warmer in the winter, making your ride more pleasant!

- Automotive self-adhesive insulation is a waterproof lightweight thermal deadener with a highly compressible closed-cell foam formulation, it absolutely doesn’t absorb moisture and has no odor

- The sound dampening mat can be applied to external partitions, firewalls, hoods, engine compartments, engine compartments, trunks, wheel arches, body panels, load floors, and internal partitions under the seat floor.

- The sound dampening material comes in handy size sheets which make it easier in terms of the cutting and installation process and it’s flexible which makes it easy to install with or without a roller.

- Strong sound insulation and absorption performance,heat insulation mat

- Easily installs,fit all kinds of vehicle type.Self sticking backing & Waterproof,dustproof.

- The surface high-fiber cloth is fiberglass. Heatproof.Block transmit sunlight, engine, exhaust pipe heat to the cab, reduce air conditioning energy consumption, saving fuel

- Slow down the car paint ageing.Because of hot weather, the front outer cover through the direct sun, high temperature inside and outside the engine, accelerated paint aging

- Keeps Heat In-Cold Out in the Winter, Keeps Cold in-Heat Out in the Summer.In the winter, the engine temperature is very high, but outside is very low when driving, which make car parts damaged easier

- 【Fireproof and Waterproof】: This car muffler mat is made of universal nbr material, flexible and stable, with strong flame retardant properties, open flame ignition, no spontaneous combustion. It is lightweight and waterproof, moisture-proof and odorless, able to isolate most of the liquid on the surface, easy to wipe dry and anti-scratch.

- 【Sound Absorption & Noise Reduction】: Three-dimensional mesh porous material, can absorb noise, install it at the engine hatch, can absorb a lot of engine noise. Installed at the door, the sound of closing the door will become dull and heavy, no longer harsh. Installed at the car roof, reduce the knocking sound of rain.

- 【Heat Insulation & Vibration Damping】: It has a good heat insulation effect, installed at the car roof, it can effectively block outdoor heat and keep the car cool. It prevents heat loss inside the car in winter, reduces the energy consumption of air conditioning and saves fuel. This product also has excellent vibration absorption capacity, inhibit engine vibration, reduce internal vibration, and extend the life of parts.

- 【Easy to Install】: The size of this car muffler mat is 39.4 * 19.7 inches, easy to cut and process, easy to install, no tools required. ①Cut the sound deadening mat to the desired size. ②Tear off the protective film on the back and stick the mat to the installation area. ③Apply appropriate pressure and press firmly to ensure a tight fit.

- 【Wide Application】: This product has a wide range of applications and can be applied to the hood, engine compartment, trunk, body panels, load floor, and interior partitions under the seat floor. It can also be used in more occasions, such as: entertainment venues, music training rooms, studios, home venues, etc.

- 🌹【Outstanding insulation】This car heat shield mat has an adhesive layer and is a versatile heat insulation material with excellent heat insulation performance. It can keep the car warm in winter and cool in summer and keep the car at a comfortable temperature.

- 🌹【Noise reduction】Car sound insulation mat are made of closed-cell foam sound insulation materials, which can effectively eliminate and block engine noise, vibration and friction noise during driving, giving you a quiet driving space and greatly improving driving comfort.

- 🌹【Advantages】The sound deadener damping mat is light in weight, does not absorb water, is resistant to oil and high temperature, and is also fire-resistant and flame-retardant.

- 🌹【Widely used】Widely used in car roofs, hoods, firewalls, chassis, interior and exterior partitions, trunks, wheel arches, body panels, under seats, trunk covers, etc.

- 🌹【Heat Shield Material】100% Brand New heat shield Car Sound Deadener, PE with aluminum material, Thickness: 10mm, High quality tri-layer, twin density lightweight foam laminate.

- 59 x 39 inch heat-resistant aluminum coating foam sound deadener and heat dampener

- Water Resistant Insulation - Protect your vehicle from rusting

- Workable Thickness for the maximum effectiveness: Abahub 0.236 inch aliminum sound dampening can be cut with scissors easily, works great over 0.079 inch butyl vibration deadening mat to reach the maximum heat insulation and sound dampening.

- Fire Resistant Hood & Firewall Insulation : Abahub aluminum coating fire-resistant insulation provides a heat barrier, which blocks the noise coming out of your engine; prevents the heat from the engine from damaging the paint on the hood.

- What You Get - a lightweight and rolled 16 sqft heat shield insulation, easy to work on your car, truck, rv, or any other vehicle.

- Specifications&SIZE:Thickness 394 mil / 10mm,1pcs 40x60inch Sound Deadener (single piece 16.36 sqft),Total coverage area - 16.36 ft²,Material: Aluminum foil/PE Foam,working Temperature Range: -40°F ~ 300°F.

- Heat Insulation Material - Sound dampening mat is made of high density closed cell foam, with waterproof Aluminum surface,so it can reflects and blocks most of the heat from the sun, machine or operation of the engine,, reduce air conditioning energy consumption, saving fuel.

- Block Noise- Car Sound Deadening Foam Mat made of insulation foam which blocks the noise coming out of your engine; prevents the heat from the engine from damaging the paint on the hood.

- Easy to Cut and Install-Easily installs,fit all kinds of vehicle type. this insulation foam is easy to cut, peel and apply,Self sticking backing & Waterproof,dustproof.

- Widely used - Noise sound deadener can be applied to car roofs, hoods, firewalls, chassis, interior and exterior partitions, trunks,chassis, trunk, engine, seat and so on,Widely used in trucks, SUV, cars, boats and more.

- Specifications - The car engine sound deadener measures approx. 40 inch x 60 inch/ 1 x 1.5m, Thickness: 394mil/10mmm, Total coverage area - 16.36sqft, working Temperature Range: -40°F ~ 300°F.

- Outstanding insulation - Heat Sound Deadening Insulation Mat has excellent sound insulation and vibration absorption performance, reduce the vibration sound of the engine, the collision sound of the door, the noise outside the car, etc, giving you a quiet driving space and greatly improving driving comfort.

- Heat Insulation Material - Sound dampening mat is made of high density closed cell foam, with waterproof Aluminum surface,so it can reflects and blocks most of the heat from the sun, machine or operation of the engine,reduce air conditioning energy consumption, saving fuel.

- Easy to Cut and Install - our Sound deadening mat is Easy to cut and install,fit all kinds of vehicle type. this insulation foam is easy to cut, peel and apply,Self sticking backing & Waterproof,dustproof.

- Widely used - Noise sound deadener can be applied to car roofs, hoods, firewalls, chassis, interior and exterior partitions, trunks,chassis, trunk, engine, seat and so on,Widely used in trucks, SUV, cars, boats and more.

- Sound deadening material size: Nominal thickness 197 mils; Total coverage area of 21.6 sq.feet; Nominal sheet Size 40x40 inches-2pack. The thicker the material the more effective insulation you get! working Temperature Range: -40°F ~ 300°F

- Heat Insulation and Vibration Deadener: Effectively blocks 98% of radiant heat transfer. Sound deadening mat is a very versatile insulation material with excellent thermal barrier properties that will block engine, exhaust, & summer heat, ensuring your vehicle stays cooler in the summer and warmer in the winter, making your ride more pleasant!

- Automotive self-adhesive insulation is a waterproof lightweight thermal deadener with a highly compressible closed-cell foam formulation, it absolutely doesn’t absorb moisture and has no odor

- The sound dampening mat can be applied to external partitions, firewalls, hoods, engine compartments, engine compartments, trunks, wheel arches, body panels, load floors, and internal partitions under the seat floor.

- The sound dampening material comes in handy size sheets which make it easier in terms of the cutting and installation process and it’s flexible which makes it easy to install with or without a roller.

SEOCONTENT-START

January, 2023 * * * IMPORTANT SAFETY RECALL REMINDER * * * According to our records, your 2021 F-150 Ford Truck has not had necessary safety recall repairs made. We urge you to have the free repair performed at your local dealership as soon as possible. Recall Number and Description: 22S53 – F-150 Loss of Mobility What is the issue? On your vehicle, underbody insulator(s) may have been installed in error. When present, underbody insulators may loosen and contact the aluminum driveshaft, resulting in marking or scoring of the driveshaft. Continued contact may result in driveshaft fracture. A fractured driveshaft poses the risks of loss of motive power while driving, unintended vehicle movement while the vehicle is in park if the parking brake is not applied, and secondary damage to surrounding components. A fractured driveshaft may also contact the ground which may cause loss of control of the vehicle while driving. A fractured driveshaft increases the risk of injury or crash. If you have questions or concerns, please contact our Ford Customer Relationship Center at 1-866-436-7332. If you wish to contact us through the Internet, our address is: ford.com/support. Thank you for your attention to this very important matter. Enero de, 2023 * * * RECORDATORIO IMPORTANTE PROGRAMA DE SEGURIDAD * * * SegUR nuestros registros, no se realizaron en sur 2021 F-150 Ford Truck las reparaciones necesarias correspondientes a la campaña de seguridad. Le solicitamos que realice esta reparación gratuita en su distribuidor local lo antes posible. Número y descripción de la campaña: 22S53 – F-150 Pérdida de movilidad ¿Cuál es el problema? Es posible que en su vehículo, por error, se hayan instalado aisladores en la parte inferior de la carrocería. Cuando están presentes, los aisladores de la parte inferior de la carrocería podrían aflojarse y tener contacto con la flecha de mando de aluminio, lo que genera marcas o rayados de la flecha de mando. El contacto continuo podría tener como resultado la fractura de la flecha de mando. Una fractura de la flecha de mando pone en riesgo la pérdida de la potencia motriz mientras maneja, un movimiento accidental del vehículo mientras está en estacionamiento si el freno de estacionamiento no se aplica y daño secundario en los componentes de los alrededores. Una flecha de mando fracturada también podría entrar en contacto con la tierra que podría causar la pérdida de control del vehículo mientras maneja. Una flecha de mando fracturada aumenta el riesgo de choque o de sufrir lesiones o choque. Si tiene dudas o preguntas, comuníquese con nuestro Centro de Relación con Clientes Ford al 1-866-436-7332. Si desea ponerse en contacto con nosotros a través de Internet, nuestra dirección es: ford.com/support. Gracias por su atenciic en este asunto sumamente importante. © Copyright 2023 Ford Motor Company 1 of 2 000000000000062 / 123 / 62 62 SEE OTHER SIDE FOR OPENING INSTRUCTIONS SEE OTHER SIDE FOR OPENING INSTRUCTIONS REMOVE THESE SIDE EDGES FIRST Š THEN FOLD, CREASE AND TEAR THIS STUB ALONG PERFORATION Š REMOVE THESE SIDE EDGES FIRST Š THEN FOLD, CREASE AND TEAR THIS STUB ALONG PERFORATION Š P.O. BOX 1904 DEARBORN, MI 48121-1904 Presorted STD US Postage PAID R K C 0004088 A / 000000000000062 / 62 ²À À À²

**************************************************************************************************************

September 2022 Ford Motor Company Ford Customer Service Division P. O. Box 1904 Dearborn, Michigan 48121 1904 * * * IMPORTANT SAFETY RECALL * * * Safety Recall Notice 22S53 / NHTSA Recall 22V623 2021 F-150 Ford Truck Your Vehicle Identification Number (VIN): This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. Ford Motor Company has decided that a defect which relates to motor vehicle safety exists in your vehicle, with the VIN shown above. We apologize for this situation and want to assure you that, with your assistance, we will correct this condition. Our commitment, together with your dealer, is to provide you with the highest level of service and support. What is the issue? On your vehicle, underbody insulator(s) may have been installed in error. When present, underbody insulators may loosen and contact the aluminum driveshaft, resulting in marking or scoring of the driveshaft. Continued contact may result in driveshaft fracture. What is the risk? A fractured driveshaft poses the risks of loss of motive power while driving, unintended vehicle movement while the vehicle is in park if the parking brake is not applied, and secondary damage to surrounding components. A fractured driveshaft may also contact the ground which may cause loss of control of the vehicle while driving. A fractured driveshaft increases the risk of injury or crash. What will Ford and your dealer do? Ford Motor Company has authorized your dealer to inspect for the presence of either the driver or passenger-side underbody insulator(s). If present, your dealer will secure the underbody insulators, and inspect the driveshaft, fuel vapor lines and electrical connectors for damage and repair as necessary free of charge (parts and labor). How long will it take? The time needed for this repair is less than one-half day. However, due to service scheduling requirements, your dealer may need your vehicle for a longer period of time. Additional time may be required to allow the engine to cool prior to performing this repair. In addition, your vehicle will require an inspection to determine if parts need to be ordered. What should you do? Please call your dealer without delay and request a service date for Recall 22S53. Provide the dealer with your VIN, which is printed near your name at the beginning of this letter. Ford has not issued instructions to stop driving your vehicle under this safety recall. You should contact your dealer for an appointment to have your vehicle remedied as soon as practicable. You can continue to safely drive your vehicle. If you do not already have a servicing dealer, you can access ford.com/support for dealer addresses, maps, and driving instructions. Ford Motor Company wants you to have this safety recall completed on your vehicle. The vehicle owner is responsible for making arrangements to have the work completed. Ford Motor Company can deny coverage for any vehicle damage that may result from the failure to have this recall performed on a timely basis. Therefore, please have this recall performed as soon as possible. © Copyright 2022 Ford Motor Company 08367 22S53 NI/DTB122S531 1 of 4 A/1/000001/1 771649467889 A/1/000001/1 JOHN A. SAMPLE 123 SAMPLE ST SAMPLE CITY, MI 12345-6789 What should you do? (continued) Please note: Federal law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days. NOTE: You can receive information about Recalls and Customer Satisfaction Programs through our FordPass App. The app can be downloaded through the App Store or Google Play. In addition there are other features such as reserving parking in certain locations and controlling certain functions on your vehicle (lock or unlock doors, remote start) if it is equipped to allow control. Do you need a rental vehicle? If your dealer determines that driveshaft replacement is required and needs your vehicle overnight, your dealer is authorized to provide a rental vehicle for your personal transportation at no charge (except for fuel and insurance) while your vehicle is at the dealership for repairs. Please see your dealer for guidelines and limitations. Have you previously paid for this repair? If you have previously paid for a repair that addresses the issue described in this letter, you still need to have this recall performed to ensure the correct parts and procedures were used. You may be eligible for a refund of previously paid repairs. Refunds will only be provided for service related to driveshaft replacement. To verify eligibility and expedite reimbursement, give your paid original receipt to your dealer. Refund requests may also be sent directly to Ford Motor Company. To request your refund from Ford, send the refund request with all required documentation, including your original repair receipt (no photocopies), to Ford Motor Company at P.O. Box 6251, Dearborn, Michigan 48121-6251. Refund requests mailed to this address may take up to 60 days to process. Your original receipt will be returned to you. Detailed information regarding eligibility for Ford’s reimbursement program and documentation requirements may be obtained by contacting the Ford Customer Relationship Center at 1-866-436-7332. What if you no longer own this vehicle? If you no longer own this vehicle, and have an address for the current owner, please forward this letter to the new owner. You received this notice because government regulations require that notification be sent to the last known owner of record. Our records are based primarily on state registration and title data, which indicate that you are the current owner. Can we assist you further? If you have difficulties getting your vehicle repaired promptly and without charge, please contact your dealership’s Service Manager for assistance. RETAIL OWNERS: If you have questions or concerns, please contact our Ford Customer Relationship Center at 1-866-436-7332 and one of our representatives will be happy to assist you. If you wish to contact us through the Internet, our address is: ford.com/support. For the hearing impaired call 1-800-232-5952 (TDD). Representatives are available Monday through Friday: 8:00AM – 8:00PM (Eastern Time). FLEET OWNERS: If you have questions or concerns, please contact our Ford Pro Contact Center at 1-800-34-FLEET, choose Option #1, and one of our representatives will be happy to assist you. If you wish to contact us through the Internet, our address is: fleet.ford.com. Representatives are available Monday through Friday: 7:00AM – 11:00PM and Saturday 7:00AM – 5:00PM (Eastern Time). If you are still having difficulty getting your vehicle repaired in a reasonable time or without charge, you may write the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave. S.E., Washington, D.C. 20590 or call the toll free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153) or go to NHTSA.gov. Reference NHTSA Safety Recall 22V623. Thank you for your attention to this important matter. Ford Customer Service Division © Copyright 2022 Ford Motor Company 08367 22S53 NI/DTB122S531 2 of 4 A/2/000001/1 * * * CAMPAÑA DE SEGURIDAD IMPORTANTE * * * Aviso de Campaña de seguridad 22S53 / Campaña 22V623 de la NHTSA 2021 F-150 Ford Truck Número de identificación del vehículo (VIN): Este aviso se le envía de acuerdo con la Ley Nacional de Seguridad de Tránsito y Vehículos Motorizados de los EE. UU. Ford Motor Company ha determinado que existe un defecto relacionado con la seguridad de su vehículo, con el VIN que aparece más arriba. Lamentamos esta situación y deseamos asegurarle que, con su ayuda, corregiremos el problema. Nuestro compromiso, junto con el de su distribuidor, es ofrecerle servicio y apoyo de alto nivel. ¿Cuál es el problema? Es posible que en su vehículo, por error, se hayan instalado aisladores en la parte inferior de la carrocería. Cuando están presentes, los aisladores de la parte inferior de la carrocería podrían aflojarse y tener contacto con la flecha de mando de aluminio, lo que genera marcas o rayados de la flecha de mando. El contacto continuo podría tener como resultado la fractura de la flecha de mando. ¿Qué riesgo existe? Una fractura de la flecha de mando pone en riesgo la pérdida de la potencia motriz mientras maneja, un movimiento accidental del vehículo mientras está en estacionamiento si el freno de estacionamiento no se aplica y daño secundario en los componentes de los alrededores. Una flecha de mando fracturada también podría entrar en contacto con la tierra que podría causar la pérdida de control del vehículo mientras maneja. Una flecha de mando fracturada aumenta el riesgo de choque o de sufrir lesiones o choque. ¿Qué medidas adoptarán Ford y su distribuidor? Ford Motor Company ha autorizado a su distribuidor a inspeccionar si hay presencia de aisladores en la parte inferior de la carrocería, del conductor o del pasajero. Si estuviesen presentes, su distribuidor asegurará los aisladores de la parte inferior de la carrocería e inspeccionará la flecha de mando, las tuberías de vapor de combustible y los conectores eléctricos en busca de daños y reparará, si fuera necesario, sin costo alguno (piezas y mano de obra). ¿Cuánto tiempo tomará? El tiempo necesario para esta reparación será de menos de medio día. Sin embargo, debido a los requisitos de planificación de servicio, es posible que su distribuidor tarde un poco más. Es posible que se necesite más tiempo para permitir que el motor se enfríe antes de realizar esta reparación. Además, se deberá realizar una inspección en su vehículo para determinar si es necesario pedir piezas. ¿Qué debe hacer? Llame a su distribuidor lo antes posible y solicite una cita de servicio para llevar a cabo la Campaña 22S53. Proporcione el VIN a su distribuidor, el cual está impreso debajo de sus datos al comienzo de esta carta. Para esta campaña de seguridad, Ford no ha emitido instrucciones de no manejar el vehículo. Deberá ponerse en contacto con su distribuidor a fin de programar una cita para solucionar este problema lo más pronto posible. Puede continuar manejando su vehículo con seguridad. Si aún no tiene un distribuidor para realizar el servicio, puede acceder a ford.com/support para conocer las direcciones de los distribuidores, ver mapas y obtener las instrucciones para llegar. Ford Motor Company le recomienda realizar esta campaña de seguridad en su vehículo. El propietario del vehículo es responsable de realizar los arreglos para llevar a cabo el trabajo. Ford Motor Company puede negar la cobertura en caso de que el vehículo hubiese sufrido daños por no haber realizado la campaña de manera oportuna. Por lo tanto, le solicitamos que realice esta campaña lo antes posible. 3 of 4 A/3/000001/1 08367 22S53 NI/DTB122S531 Septiembre de 2022 Ford Motor Company División de Servicio al Cliente de Ford P. O. Box 1904 Dearborn, Michigan 48121 © Copyright 2022 Ford, División de Servicio al Cliente 771649467889 A/3/000001/1 JOHN A. SAMPLE 123 SAMPLE ST SAMPLE CITY, MI 12345-6789 ¿Qué debe hacer? (continuación) Tenga presente que: La ley federal exige que los arrendadores de vehículos que reciban este aviso de campaña envíen una copia del mismo al arrendatario en un plazo de diez días. NOTA: Puede recibir información sobre las campañas y los programas de satisfacción del cliente a través de la aplicación FordPass. La aplicación se puede descargar a través de App Store o Google Play. Adicionalmente, existen otras funciones como reserva de estacionamientos en determinados lugares, además de control de ciertas funciones en el vehículo (bloqueo o desbloqueo de puertas, arranque remoto) si así está equipado para permitir el control. ¿Necesita un vehículo de alquiler? Si su distribuidor determina que es necesario efectuar el reemplazo de la flecha de mando y el vehículo debe permanecer en las instalaciones durante la noche, el distribuidor está autorizado a ofrecerle un vehículo de alquiler para su transporte personal sin costo (excepto combustible y seguro) mientras su vehículo se encuentre en reparación. Comuníquese con su distribuidor para conocer las pautas y limitaciones. ¿Ha pagado anteriormente por esta reparación? Si usted ha pagado previamente por una reparación que aborda el problema descrito en esta carta, igualmente se le recomienda realizar esta campaña para garantizar que se hayan utilizado las piezas y los procedimientos correctos. Es posible que cumpla con los requisitos para recibir un reembolso por las reparaciones pagadas previamente. Solo se otorgarán reembolsos por servicios relacionados con el reemplazo de la flecha de mando. Para comprobar si cumple con los requisitos y agilizar el reembolso, proporcione el recibo de pago original a su distribuidor. También puede enviar las solicitudes de reembolso directamente a Ford Motor Company. Para solicitar un reembolso a Ford, envíe la solicitud con toda la documentación requerida, incluido el recibo original de la reparación (no envíe fotocopias), a Ford Motor Company, P.O. Box 6251, Dearborn, Michigan 48121-6251. El procesamiento de las solicitudes de reembolso enviadas a esta dirección puede tardar hasta 60 días. Su recibo original le será regresado. Comuníquese con el Centro de Relación con Clientes al 1-866-436-7332 para obtener información detallada relacionada con el programa de reembolso de Ford y los requisitos de documentación. ¿Qué pasa si usted ya no es el propietario del vehículo? Si usted ya no es el propietario del vehículo y tiene la dirección del propietario actual, le solicitamos que le reenvíe esta carta. Usted recibió este aviso porque las regulaciones del gobierno exigen el envío de notificaciones al propietario conocido más reciente del registro. Nuestros registros se basan principalmente en datos estatales y de propiedad, que indican que usted es el propietario actual del vehículo. ¿Podemos hacer algo más por usted? Si tiene problemas para reparar de inmediato su vehículo y sin costo alguno, comuníquese con el Gerente de Servicio de su distribuidor para solicitar ayuda. PROPIETARIOS MINORISTAS: Si tiene dudas o preguntas, comuníquese con nuestro Centro de Relación con Clientes Ford al 1-866-436-7332 y uno de nuestros representantes con gusto lo atenderá. Si desea comunicarse con nosotros a través de Internet, nuestra dirección es ford.com/support. Las personas con problemas de audición pueden llamar al 1-800-232-5952 (TDD). Los representantes atienden de lunes a viernes, de 8:00 a.m. a 8:00 p.m. (hora del este). PROPIETARIOS DE FLOTAS: Si tiene dudas o preguntas, comuníquese con nuestro Centro de contacto de Ford Pro al 1-800-34-FLEET, elija la opción n.° 1 y uno de nuestros representantes con gusto lo atenderá. Si desea comunicarse con nosotros a través de Internet, nuestra dirección es fleet.ford.com. Los representantes atienden de lunes a viernes de 7:00 a.m. a 11:00 p.m. y sábado de 7:00 a.m. a 5:00 p.m. (hora del este). Si aun así tiene problemas para reparar su vehículo en un periodo de tiempo razonable o sin costo, puede escribir al Administrador de National Highway Traffic Safety Administration, 1200 New Jersey Ave. S.E., Washington, D.C. 20590, llamar a la Línea directa de seguridad vehicular al 1-888-327-4236 (TTY: 1-800-424-9153) o visitar NHTSA.gov. Referencia: Campaña de seguridad 22V623 de la NHTSA. Gracias por su atención en este asunto sumamente importante. Ford, División de Servicio al Cliente 4 of 4 A/4/000001/1 08367 22S53 NI/DTB122S531 © Copyright 2022 Ford, División de Servicio al Cliente

**************************************************************************************************************